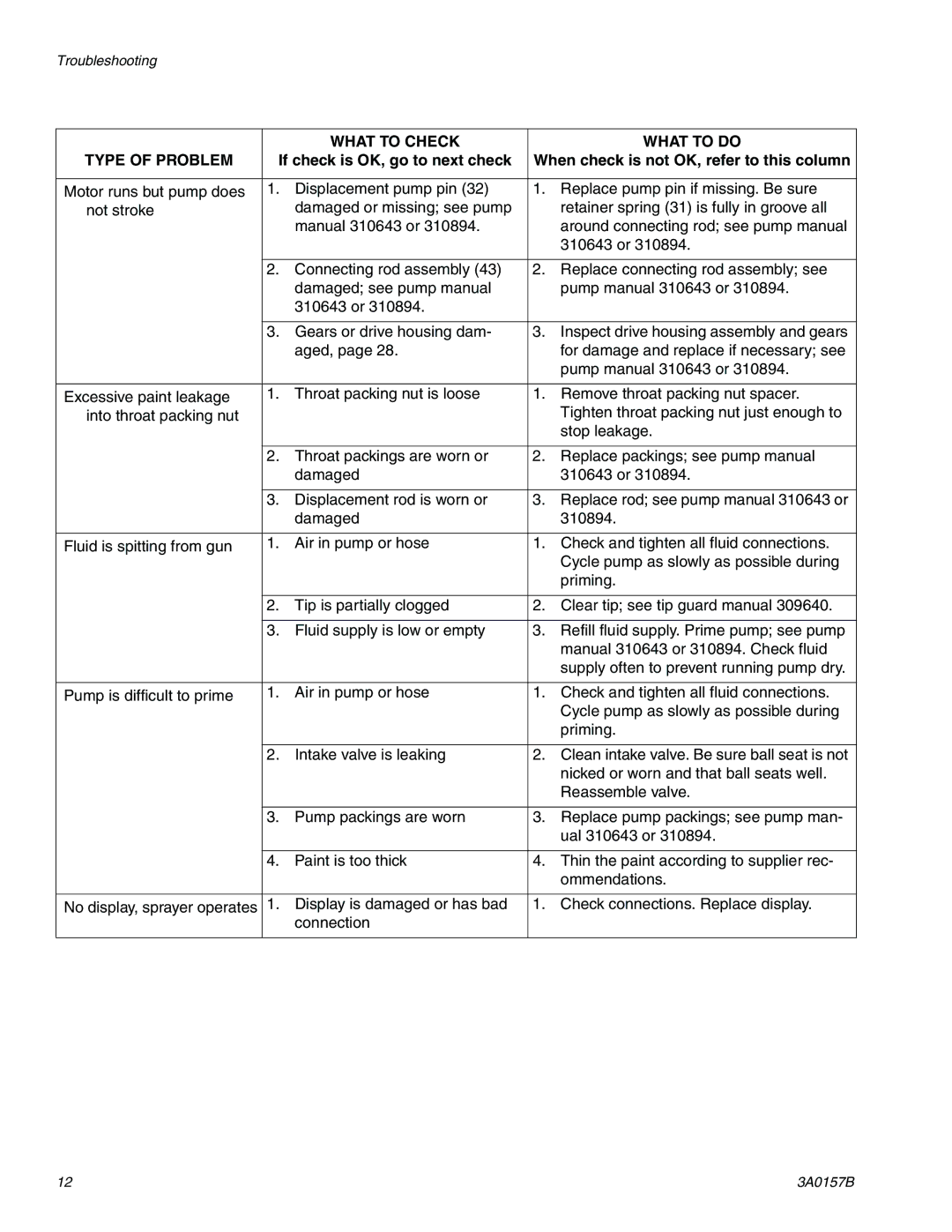

Troubleshooting

|

| WHAT TO CHECK |

| WHAT TO DO |

TYPE OF PROBLEM | If check is OK, go to next check | When check is not OK, refer to this column | ||

|

|

|

|

|

Motor runs but pump does | 1. | Displacement pump pin (32) | 1. | Replace pump pin if missing. Be sure |

not stroke |

| damaged or missing; see pump |

| retainer spring (31) is fully in groove all |

|

| manual 310643 or 310894. |

| around connecting rod; see pump manual |

|

|

|

| 310643 or 310894. |

|

|

|

|

|

| 2. | Connecting rod assembly (43) | 2. | Replace connecting rod assembly; see |

|

| damaged; see pump manual |

| pump manual 310643 or 310894. |

|

| 310643 or 310894. |

|

|

|

|

|

|

|

| 3. | Gears or drive housing dam- | 3. | Inspect drive housing assembly and gears |

|

| aged, page 28. |

| for damage and replace if necessary; see |

|

|

|

| pump manual 310643 or 310894. |

|

|

|

|

|

Excessive paint leakage | 1. | Throat packing nut is loose | 1. | Remove throat packing nut spacer. |

into throat packing nut |

|

|

| Tighten throat packing nut just enough to |

|

|

|

| stop leakage. |

|

|

|

|

|

| 2. | Throat packings are worn or | 2. | Replace packings; see pump manual |

|

| damaged |

| 310643 or 310894. |

|

|

|

|

|

| 3. | Displacement rod is worn or | 3. | Replace rod; see pump manual 310643 or |

|

| damaged |

| 310894. |

|

|

|

|

|

Fluid is spitting from gun | 1. | Air in pump or hose | 1. | Check and tighten all fluid connections. |

|

|

|

| Cycle pump as slowly as possible during |

|

|

|

| priming. |

|

|

|

|

|

| 2. | Tip is partially clogged | 2. | Clear tip; see tip guard manual 309640. |

|

|

|

|

|

| 3. | Fluid supply is low or empty | 3. | Refill fluid supply. Prime pump; see pump |

|

|

|

| manual 310643 or 310894. Check fluid |

|

|

|

| supply often to prevent running pump dry. |

|

|

|

|

|

Pump is difficult to prime | 1. | Air in pump or hose | 1. | Check and tighten all fluid connections. |

|

|

|

| Cycle pump as slowly as possible during |

|

|

|

| priming. |

|

|

|

|

|

| 2. | Intake valve is leaking | 2. | Clean intake valve. Be sure ball seat is not |

|

|

|

| nicked or worn and that ball seats well. |

|

|

|

| Reassemble valve. |

|

|

|

|

|

| 3. | Pump packings are worn | 3. | Replace pump packings; see pump man- |

|

|

|

| ual 310643 or 310894. |

|

|

|

|

|

| 4. | Paint is too thick | 4. | Thin the paint according to supplier rec- |

|

|

|

| ommendations. |

|

|

|

|

|

No display, sprayer operates | 1. | Display is damaged or has bad | 1. | Check connections. Replace display. |

|

| connection |

|

|

|

|

|

|

|

12 | 3A0157B |