Troubleshooting

Troubleshooting

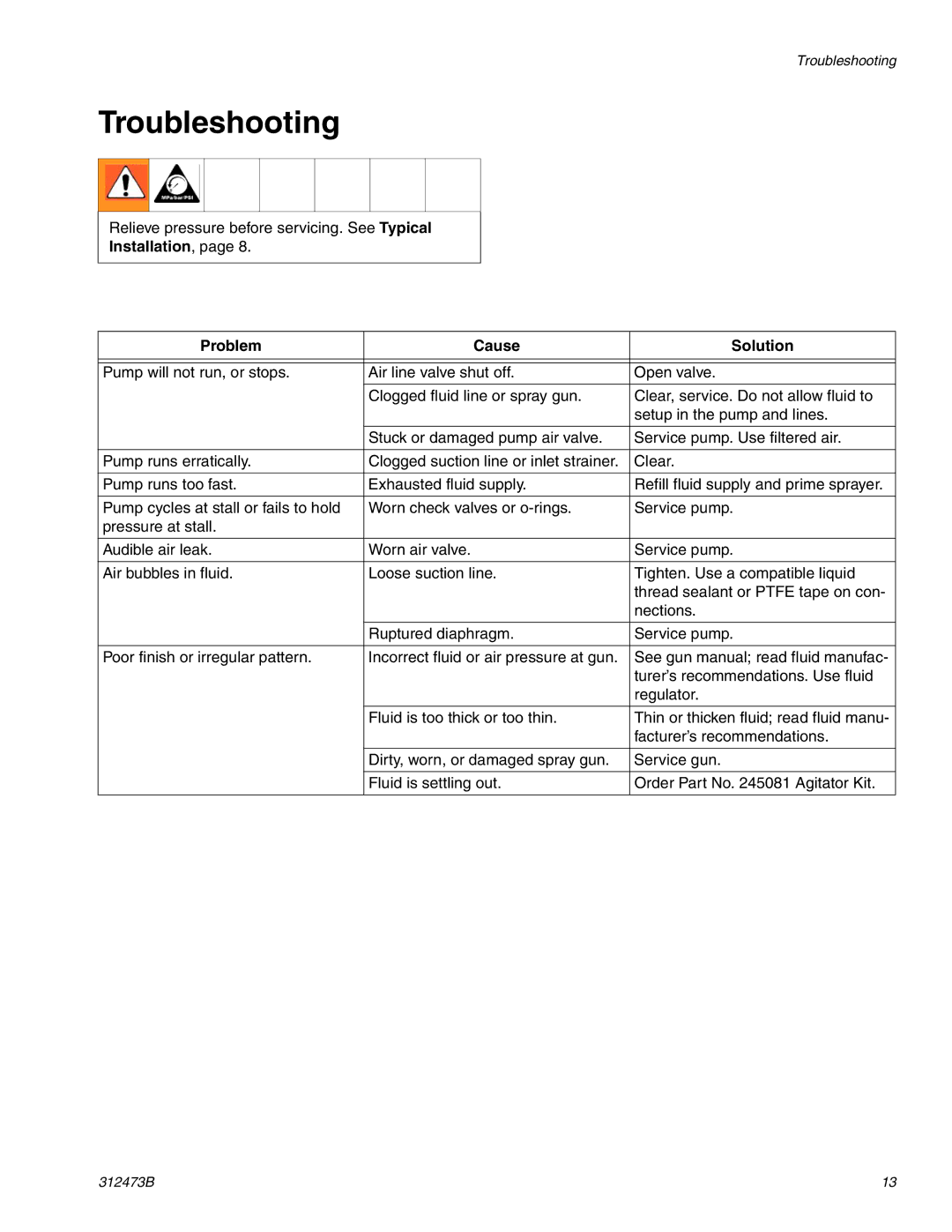

Relieve pressure before servicing. See Typical

Installation, page 8.

Problem | Cause | Solution |

|

|

|

|

|

|

Pump will not run, or stops. | Air line valve shut off. | Open valve. |

|

|

|

| Clogged fluid line or spray gun. | Clear, service. Do not allow fluid to |

|

| setup in the pump and lines. |

|

|

|

| Stuck or damaged pump air valve. | Service pump. Use filtered air. |

|

|

|

Pump runs erratically. | Clogged suction line or inlet strainer. | Clear. |

|

|

|

Pump runs too fast. | Exhausted fluid supply. | Refill fluid supply and prime sprayer. |

|

|

|

Pump cycles at stall or fails to hold | Worn check valves or | Service pump. |

pressure at stall. |

|

|

|

|

|

Audible air leak. | Worn air valve. | Service pump. |

|

|

|

Air bubbles in fluid. | Loose suction line. | Tighten. Use a compatible liquid |

|

| thread sealant or PTFE tape on con- |

|

| nections. |

|

|

|

| Ruptured diaphragm. | Service pump. |

|

|

|

Poor finish or irregular pattern. | Incorrect fluid or air pressure at gun. | See gun manual; read fluid manufac- |

|

| turer’s recommendations. Use fluid |

|

| regulator. |

|

|

|

| Fluid is too thick or too thin. | Thin or thicken fluid; read fluid manu- |

|

| facturer’s recommendations. |

|

|

|

| Dirty, worn, or damaged spray gun. | Service gun. |

|

|

|

| Fluid is settling out. | Order Part No. 245081 Agitator Kit. |

|

|

|

312473B | 13 |