Maintenance

Clean the Air Cap and Fluid Nozzle

![]() CAUTION

CAUTION

Do not use metal tools to clean the air cap or spray tip holes as this could scratch them, and make sure the electrode wire is not damaged. Scratches in the air cap or spray tip or a damaged electrode wire can distort the spray pattern.

Equipment needed:

DSoft bristle brush

DCompatible solvent

Procedure:

![]() WARNING

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury, follow the Pressure Relief Procedure on page 11 whenever you stop spraying, before installing or cleaning the fluid nozzle, and whenever you are instructed to relieve the pressure.

1.Relieve the pressure.

2.Remove the air cap assembly.

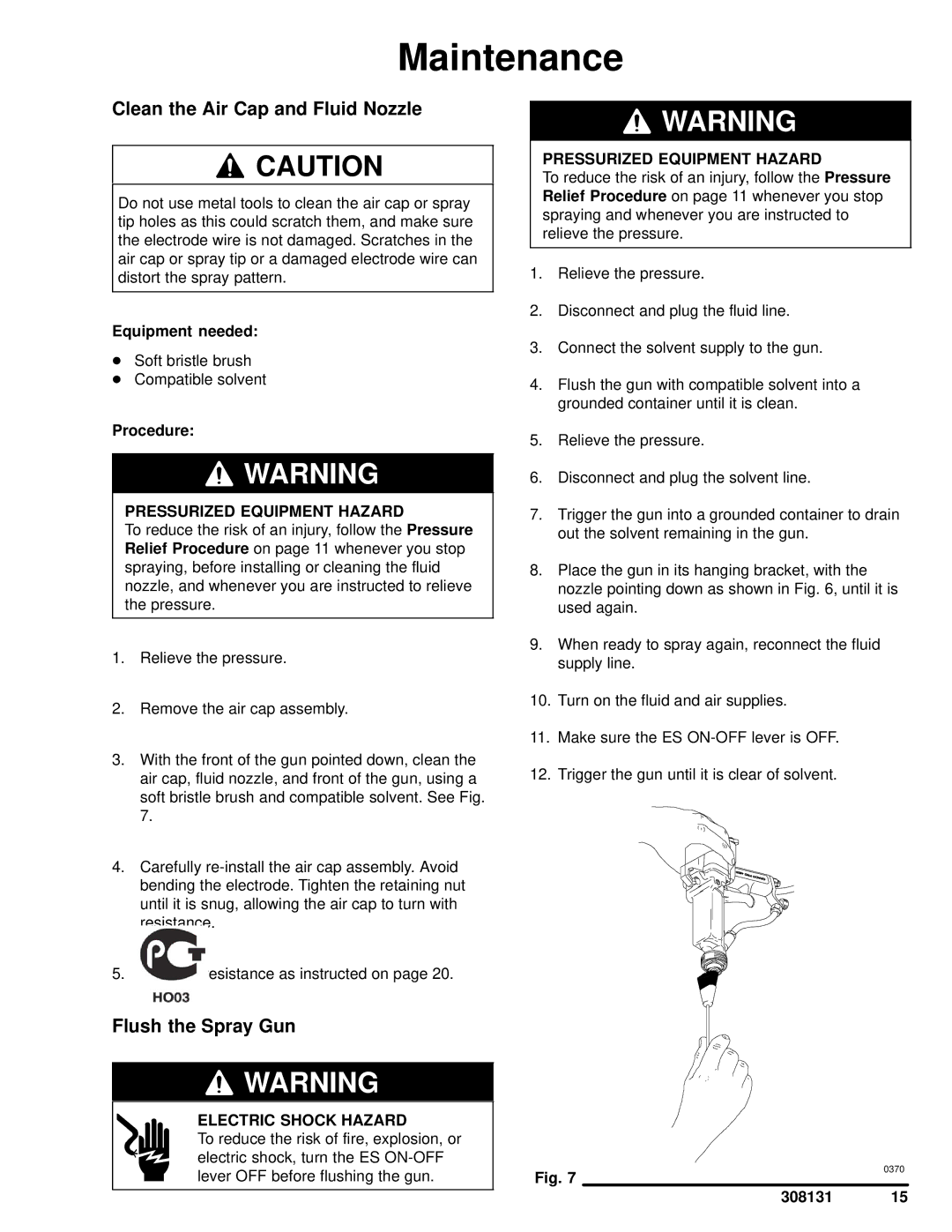

3.With the front of the gun pointed down, clean the air cap, fluid nozzle, and front of the gun, using a soft bristle brush and compatible solvent. See Fig. 7.

4.Carefully

5.Test gun resistance as instructed on page 20.

Flush the Spray Gun

![]() WARNING

WARNING

ELECTRIC SHOCK HAZARD

![]() WARNING

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury, follow the Pressure Relief Procedure on page 11 whenever you stop spraying and whenever you are instructed to relieve the pressure.

1.Relieve the pressure.

2.Disconnect and plug the fluid line.

3.Connect the solvent supply to the gun.

4.Flush the gun with compatible solvent into a grounded container until it is clean.

5.Relieve the pressure.

6.Disconnect and plug the solvent line.

7.Trigger the gun into a grounded container to drain out the solvent remaining in the gun.

8.Place the gun in its hanging bracket, with the nozzle pointing down as shown in Fig. 6, until it is used again.

9.When ready to spray again, reconnect the fluid supply line.

10.Turn on the fluid and air supplies.

11.Make sure the ES

12.Trigger the gun until it is clear of solvent.

To reduce the risk of fire, explosion, or electric shock, turn the ES

Fig. 7

0370