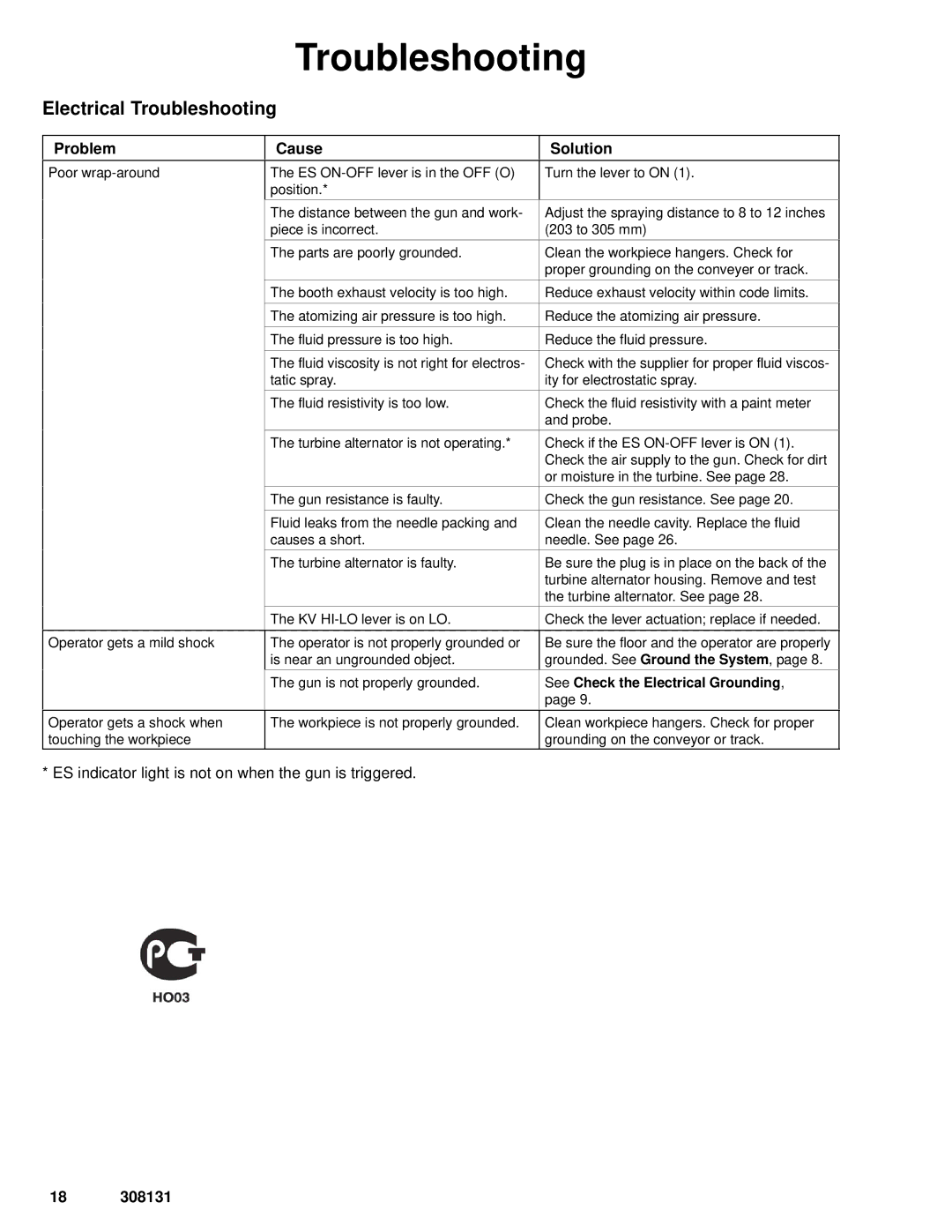

Troubleshooting

Electrical Troubleshooting

Problem

Cause

Solution

Poor

The ES

Turn the lever to ON (1).

The distance between the gun and work- | Adjust the spraying distance to 8 to 12 inches |

piece is incorrect. | (203 to 305 mm) |

|

|

The parts are poorly grounded. | Clean the workpiece hangers. Check for |

| proper grounding on the conveyer or track. |

The booth exhaust velocity is too high. | Reduce exhaust velocity within code limits. |

|

|

The atomizing air pressure is too high. | Reduce the atomizing air pressure. |

|

|

The fluid pressure is too high. | Reduce the fluid pressure. |

|

|

The fluid viscosity is not right for electros- | Check with the supplier for proper fluid viscos- |

tatic spray. | ity for electrostatic spray. |

|

|

The fluid resistivity is too low. | Check the fluid resistivity with a paint meter |

| and probe. |

The turbine alternator is not operating.*

Check if the ES

| The gun resistance is faulty. | Check the gun resistance. See page 20. |

|

|

|

| Fluid leaks from the needle packing and | Clean the needle cavity. Replace the fluid |

| causes a short. | needle. See page 26. |

|

|

|

| The turbine alternator is faulty. | Be sure the plug is in place on the back of the |

|

| turbine alternator housing. Remove and test |

|

| the turbine alternator. See page 28. |

| The KV | Check the lever actuation; replace if needed. |

|

|

|

Operator gets a mild shock | The operator is not properly grounded or | Be sure the floor and the operator are properly |

| is near an ungrounded object. | grounded. See Ground the System, page 8. |

|

|

|

| The gun is not properly grounded. | See Check the Electrical Grounding, |

|

| page 9. |

|

|

|

Operator gets a shock when touching the workpiece

The workpiece is not properly grounded.

Clean workpiece hangers. Check for proper grounding on the conveyor or track.

* ES indicator light is not on when the gun is triggered.

18 308131