Setup

Adjust Spray Pattern

Do not exceed 100 psi (0.7 MPa, 7 bar) maximum fluid and air pressure. Higher pressures can cause parts to rupture and result in serious injury.

Use the fluid pressure regulator to adjust the spray gun fluid flow. Some models are equipped with a fluid control knob to make pre- cise fluid flow adjustments.

NOTICE

Use caution when operating the fluid con- trol knob near the closed position. The plastic needle tip may be damaged if forced too hard against the nozzle seat by the fluid control knob.

Follow these steps to establish the correct fluid flow and air flow:

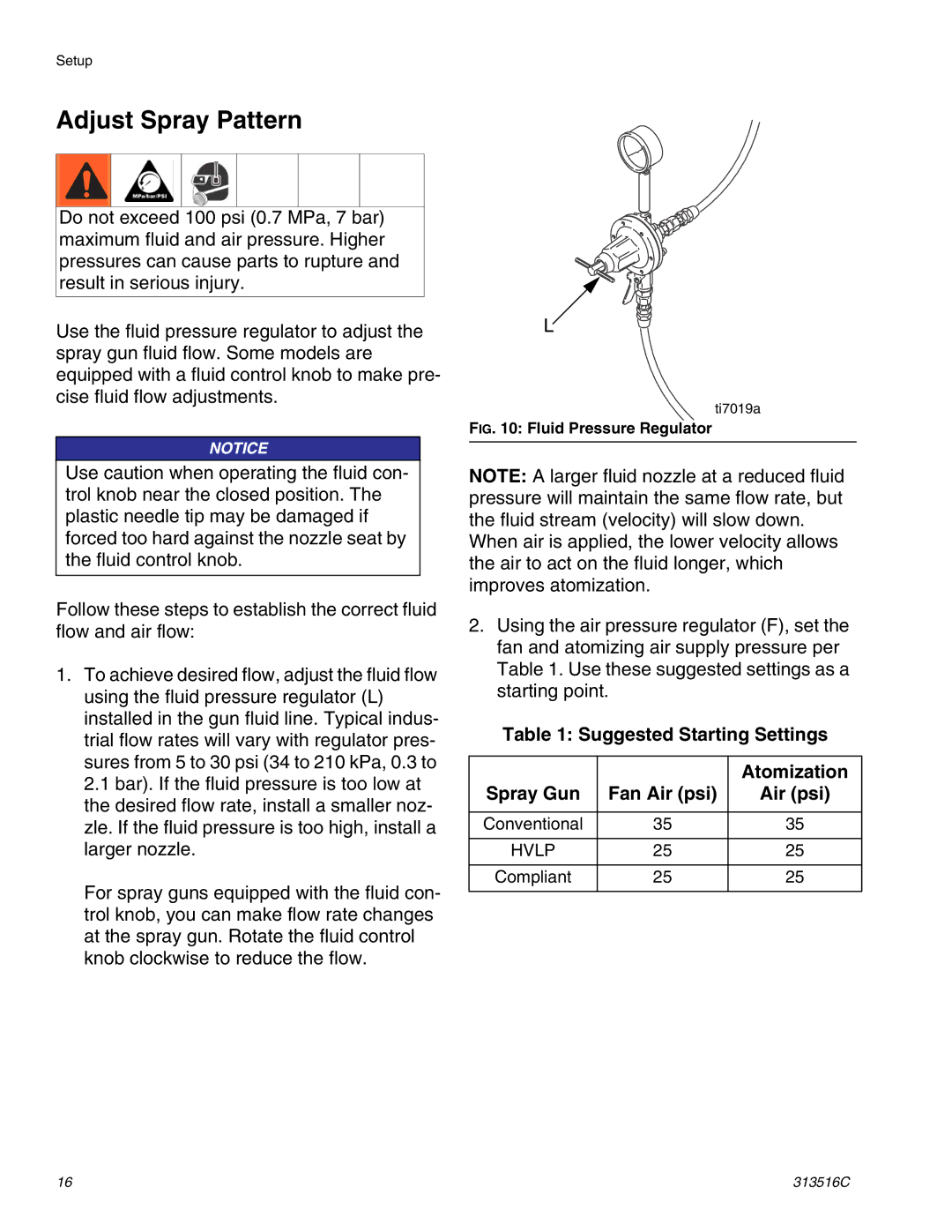

1.To achieve desired flow, adjust the fluid flow using the fluid pressure regulator (L) installed in the gun fluid line. Typical indus- trial flow rates will vary with regulator pres- sures from 5 to 30 psi (34 to 210 kPa, 0.3 to 2.1 bar). If the fluid pressure is too low at the desired flow rate, install a smaller noz- zle. If the fluid pressure is too high, install a larger nozzle.

For spray guns equipped with the fluid con- trol knob, you can make flow rate changes at the spray gun. Rotate the fluid control knob clockwise to reduce the flow.

L

ti7019a

FIG. 10: Fluid Pressure Regulator

NOTE: A larger fluid nozzle at a reduced fluid pressure will maintain the same flow rate, but the fluid stream (velocity) will slow down.

When air is applied, the lower velocity allows the air to act on the fluid longer, which improves atomization.

2.Using the air pressure regulator (F), set the fan and atomizing air supply pressure per Table 1. Use these suggested settings as a starting point.

Table 1: Suggested Starting Settings

|

| Atomization |

Spray Gun | Fan Air (psi) | Air (psi) |

|

|

|

Conventional | 35 | 35 |

|

|

|

HVLP | 25 | 25 |

|

|

|

Compliant | 25 | 25 |

|

|

|

16 | 313516C |