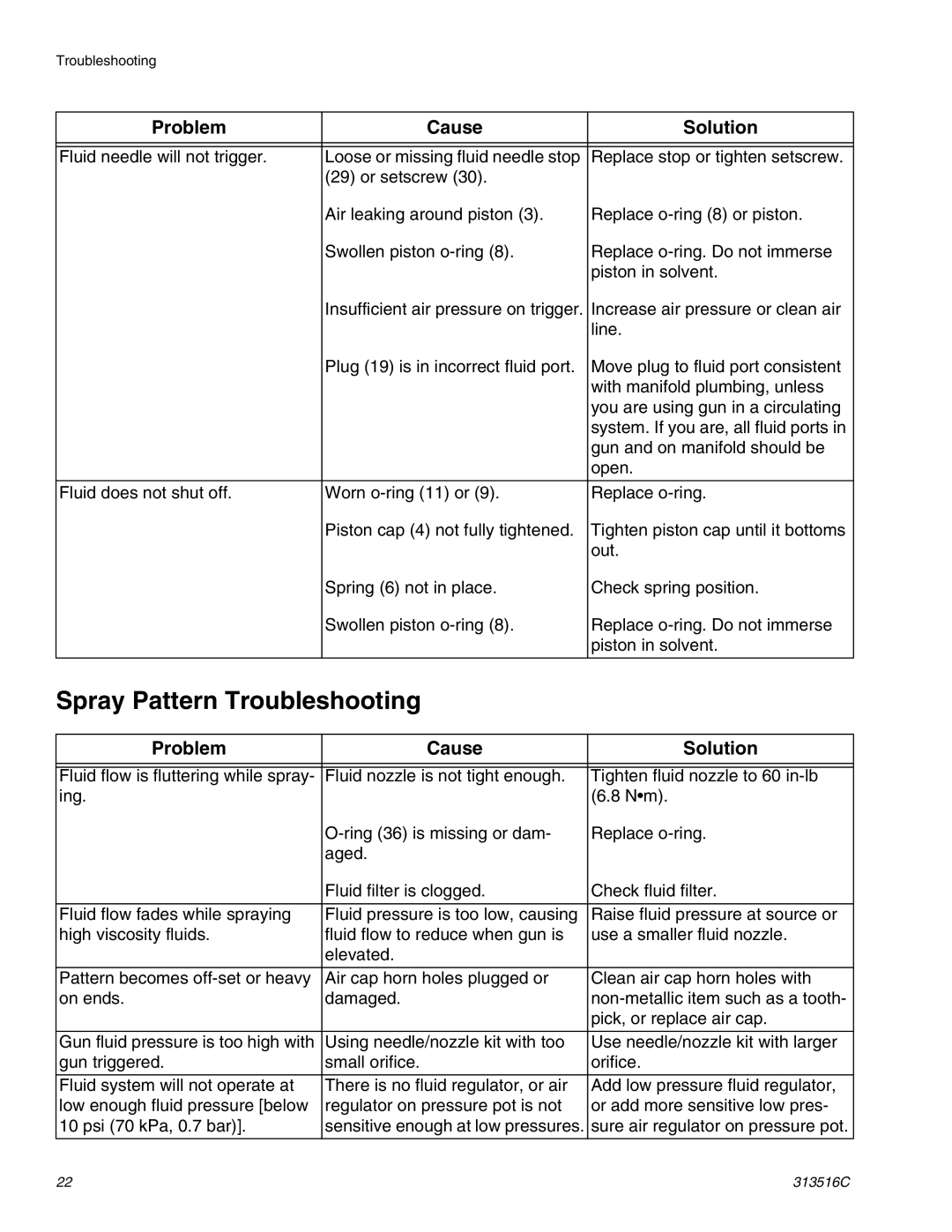

Troubleshooting

Problem | Cause | Solution |

|

|

|

|

|

|

Fluid needle will not trigger. | Loose or missing fluid needle stop | Replace stop or tighten setscrew. |

| (29) or setscrew (30). |

|

| Air leaking around piston (3). | Replace |

| Swollen piston | Replace |

|

| piston in solvent. |

| Insufficient air pressure on trigger. | Increase air pressure or clean air |

|

| line. |

| Plug (19) is in incorrect fluid port. | Move plug to fluid port consistent |

|

| with manifold plumbing, unless |

|

| you are using gun in a circulating |

|

| system. If you are, all fluid ports in |

|

| gun and on manifold should be |

|

| open. |

|

|

|

Fluid does not shut off. | Worn | Replace |

| Piston cap (4) not fully tightened. | Tighten piston cap until it bottoms |

|

| out. |

| Spring (6) not in place. | Check spring position. |

| Swollen piston | Replace |

|

| piston in solvent. |

|

|

|

Spray Pattern Troubleshooting

Problem | Cause | Solution |

|

|

|

|

|

|

Fluid flow is fluttering while spray- | Fluid nozzle is not tight enough. | Tighten fluid nozzle to 60 |

ing. |

| (6.8 N•m). |

| Replace | |

| aged. |

|

| Fluid filter is clogged. | Check fluid filter. |

|

|

|

Fluid flow fades while spraying | Fluid pressure is too low, causing | Raise fluid pressure at source or |

high viscosity fluids. | fluid flow to reduce when gun is | use a smaller fluid nozzle. |

| elevated. |

|

|

|

|

Pattern becomes | Air cap horn holes plugged or | Clean air cap horn holes with |

on ends. | damaged. | |

|

| pick, or replace air cap. |

|

|

|

Gun fluid pressure is too high with | Using needle/nozzle kit with too | Use needle/nozzle kit with larger |

gun triggered. | small orifice. | orifice. |

|

|

|

Fluid system will not operate at | There is no fluid regulator, or air | Add low pressure fluid regulator, |

low enough fluid pressure [below | regulator on pressure pot is not | or add more sensitive low pres- |

10 psi (70 kPa, 0.7 bar)]. | sensitive enough at low pressures. | sure air regulator on pressure pot. |

|

|

|

22 | 313516C |