Daily Gun Care, Flushing, and Cleaning

General System Maintenance

1.Relieve the pressure, page 10.

2.Clean the fluid and air line filters daily.

3.Check for any fluid leakage from the gun and fluid hoses. Tighten fittings or replace equipment as needed.

4.Flush the gun before changing colors and whenever you are done operating the gun.

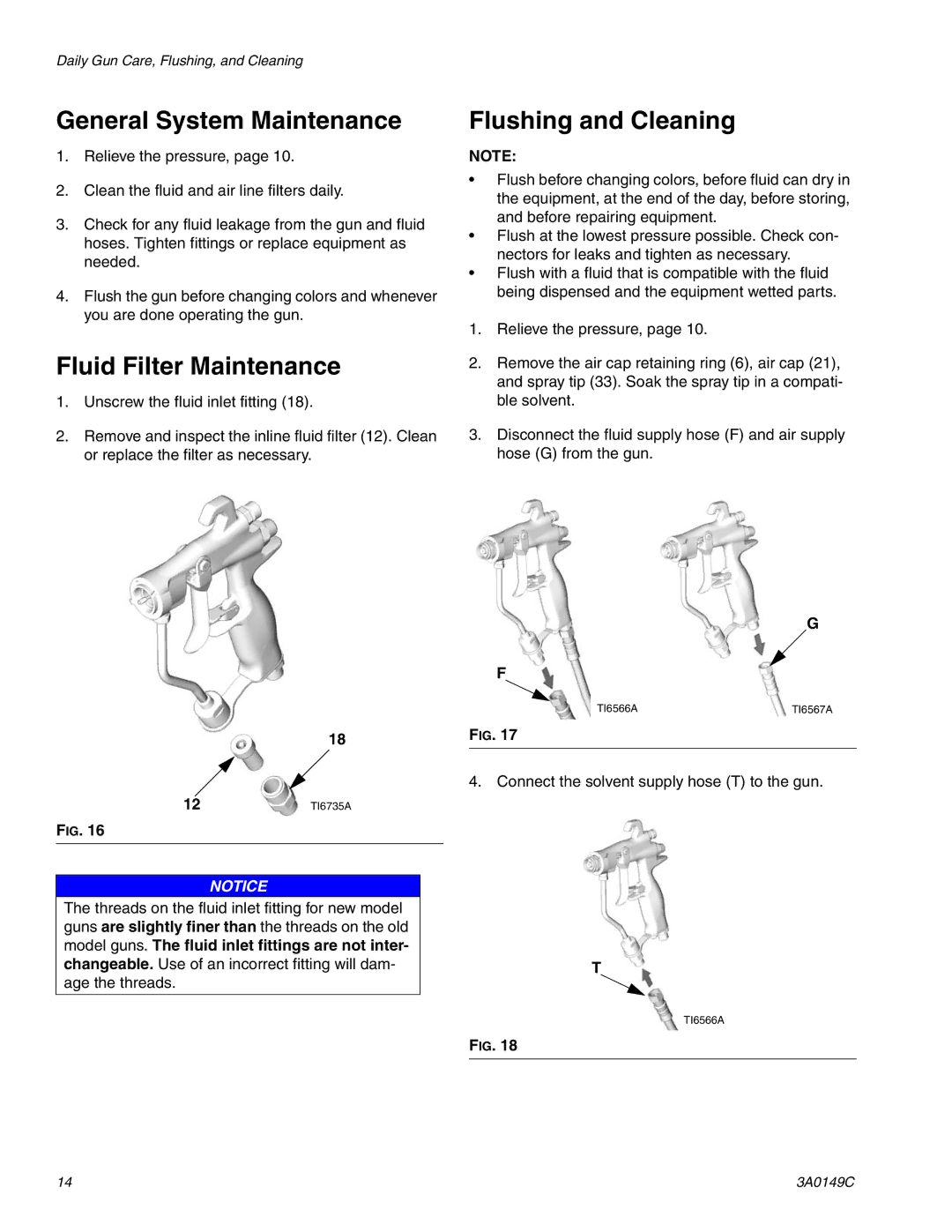

Fluid Filter Maintenance

1.Unscrew the fluid inlet fitting (18).

2.Remove and inspect the inline fluid filter (12). Clean or replace the filter as necessary.

18

12TI6735A

FIG. 16

NOTICE

The threads on the fluid inlet fitting for new model guns are slightly finer than the threads on the old model guns. The fluid inlet fittings are not inter- changeable. Use of an incorrect fitting will dam- age the threads.

Flushing and Cleaning

NOTE:

•Flush before changing colors, before fluid can dry in the equipment, at the end of the day, before storing, and before repairing equipment.

•Flush at the lowest pressure possible. Check con- nectors for leaks and tighten as necessary.

•Flush with a fluid that is compatible with the fluid being dispensed and the equipment wetted parts.

1.Relieve the pressure, page 10.

2.Remove the air cap retaining ring (6), air cap (21), and spray tip (33). Soak the spray tip in a compati- ble solvent.

3.Disconnect the fluid supply hose (F) and air supply hose (G) from the gun.

G

F

TI6566A | TI6567A |

FIG. 17

4. Connect the solvent supply hose (T) to the gun.

T

TI6566A

FIG. 18

14 | 3A0149C |