7.Reinstall the seat gasket (5b, carbide models only), seat (5c), and seat nut (5d). Torque to

NOTE:

•When reinstalling the carbide seat (5c), the tapered end of the seat (red side) must point toward the gun tip.

•The plastic seat (5c, model 24C854 guns), can be reinstalled in either direction. To avoid fluid leakage, do not reverse the direction of the plastic seat (5c) if it is worn. The seat must be replaced if it is worn.

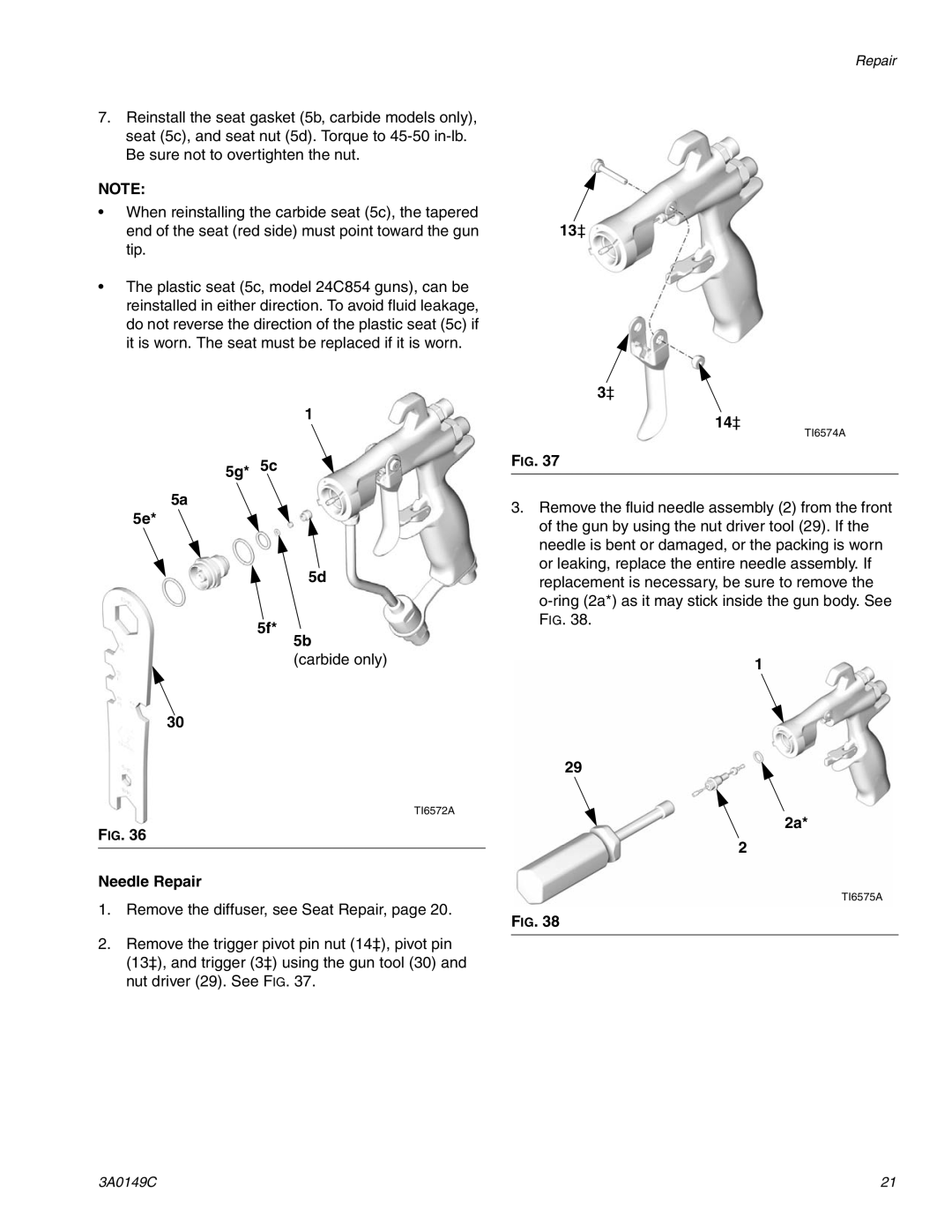

1

5g* 5c

5a

5e*

5d

5f*

5b

(carbide only)

30

TI6572A

FIG. 36

Needle Repair

1.Remove the diffuser, see Seat Repair, page 20.

2.Remove the trigger pivot pin nut (14‡), pivot pin (13‡), and trigger (3‡) using the gun tool (30) and nut driver (29). See FIG. 37.

Repair

13‡

3‡

14‡

TI6574A

FIG. 37

3.Remove the fluid needle assembly (2) from the front of the gun by using the nut driver tool (29). If the needle is bent or damaged, or the packing is worn or leaking, replace the entire needle assembly. If replacement is necessary, be sure to remove the

1

29

2a*

2

TI6575A

FIG. 38

3A0149C | 21 |