WATER COIL LOCATION AND CONNECTION

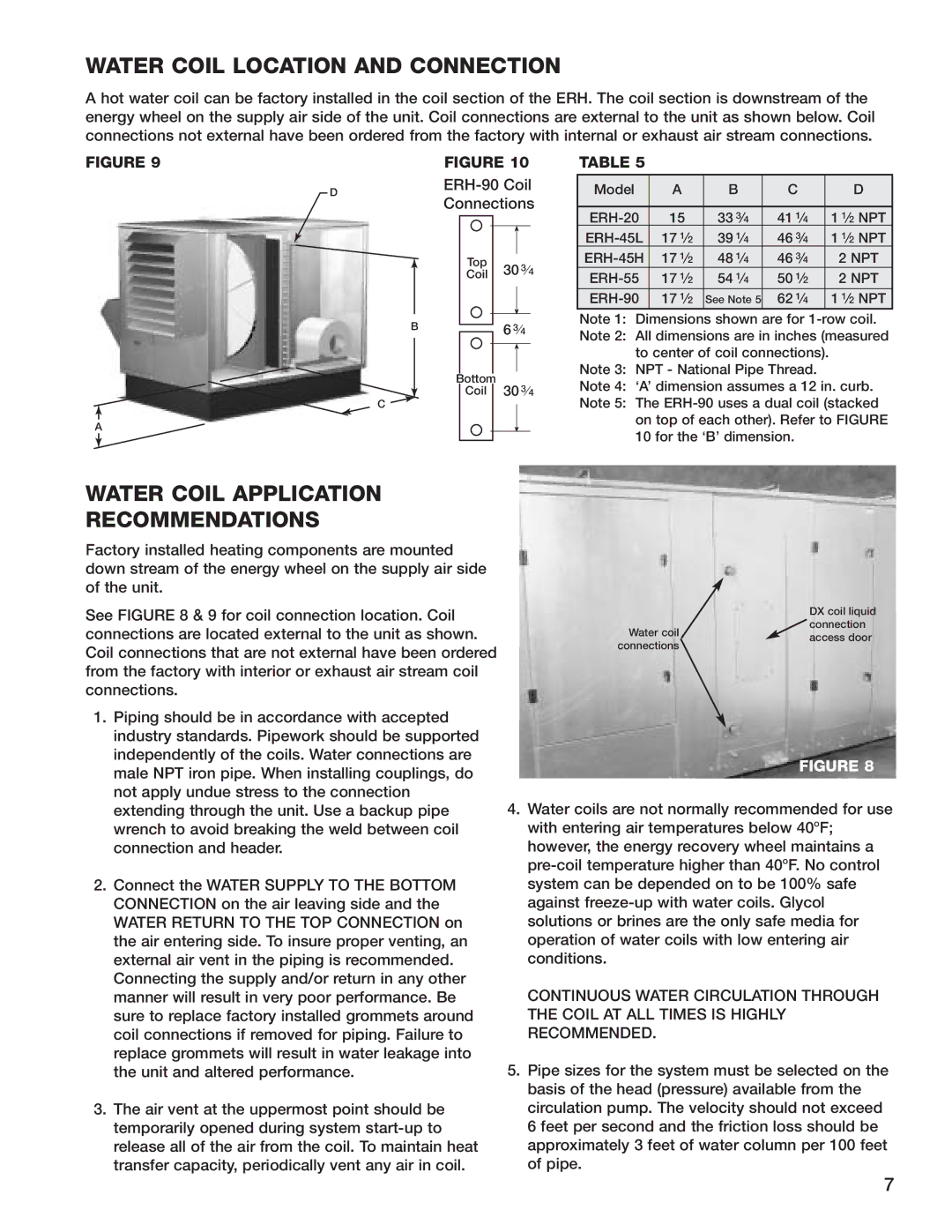

A hot water coil can be factory installed in the coil section of the ERH. The coil section is downstream of the energy wheel on the supply air side of the unit. Coil connections are external to the unit as shown below. Coil connections not external have been ordered from the factory with internal or exhaust air stream connections.

FIGURE 9

D

FIGURE 10

Top | 30 3⁄4 |

Coil |

TABLE 5

Model | A | B | C | D | |

|

|

|

|

|

|

15 | 33 3⁄4 | 41 1⁄4 | 1 1⁄2 | NPT | |

17 1⁄2 | 39 1⁄4 | 46 3⁄4 | 1 1⁄2 | NPT | |

17 1⁄2 | 48 1⁄4 | 46 3⁄4 | 2 NPT | ||

17 1⁄2 | 54 1⁄4 | 50 1⁄2 | 2 NPT | ||

17 1⁄2 | See Note 5 | 62 1⁄4 | 1 1⁄2 | NPT | |

A

B![]() 6 3⁄4

6 3⁄4

Bottom | 30 | 3⁄ |

Coil | ||

| 4 |

C ![]()

Note 1: Dimensions shown are for

Note 2: All dimensions are in inches (measured to center of coil connections).

Note 3: NPT - National Pipe Thread.

Note 4: ‘A’ dimension assumes a 12 in. curb.

Note 5: The

WATER COIL APPLICATION

RECOMMENDATIONS

Factory installed heating components are mounted down stream of the energy wheel on the supply air side of the unit.

See FIGURE 8 & 9 for coil connection location. Coil connections are located external to the unit as shown. Coil connections that are not external have been ordered from the factory with interior or exhaust air stream coil connections.

1.Piping should be in accordance with accepted industry standards. Pipework should be supported independently of the coils. Water connections are male NPT iron pipe. When installing couplings, do not apply undue stress to the connection extending through the unit. Use a backup pipe wrench to avoid breaking the weld between coil connection and header.

2.Connect the WATER SUPPLY TO THE BOTTOM CONNECTION on the air leaving side and the WATER RETURN TO THE TOP CONNECTION on the air entering side. To insure proper venting, an external air vent in the piping is recommended. Connecting the supply and/or return in any other manner will result in very poor performance. Be sure to replace factory installed grommets around coil connections if removed for piping. Failure to replace grommets will result in water leakage into the unit and altered performance.

3.The air vent at the uppermost point should be temporarily opened during system

DX coil liquid

connection

Water coil![]() access door connections

access door connections

FIGURE 8

4.Water coils are not normally recommended for use with entering air temperatures below 40oF; however, the energy recovery wheel maintains a

CONTINUOUS WATER CIRCULATION THROUGH THE COIL AT ALL TIMES IS HIGHLY RECOMMENDED.

5.Pipe sizes for the system must be selected on the basis of the head (pressure) available from the circulation pump. The velocity should not exceed 6 feet per second and the friction loss should be approximately 3 feet of water column per 100 feet of pipe.

7