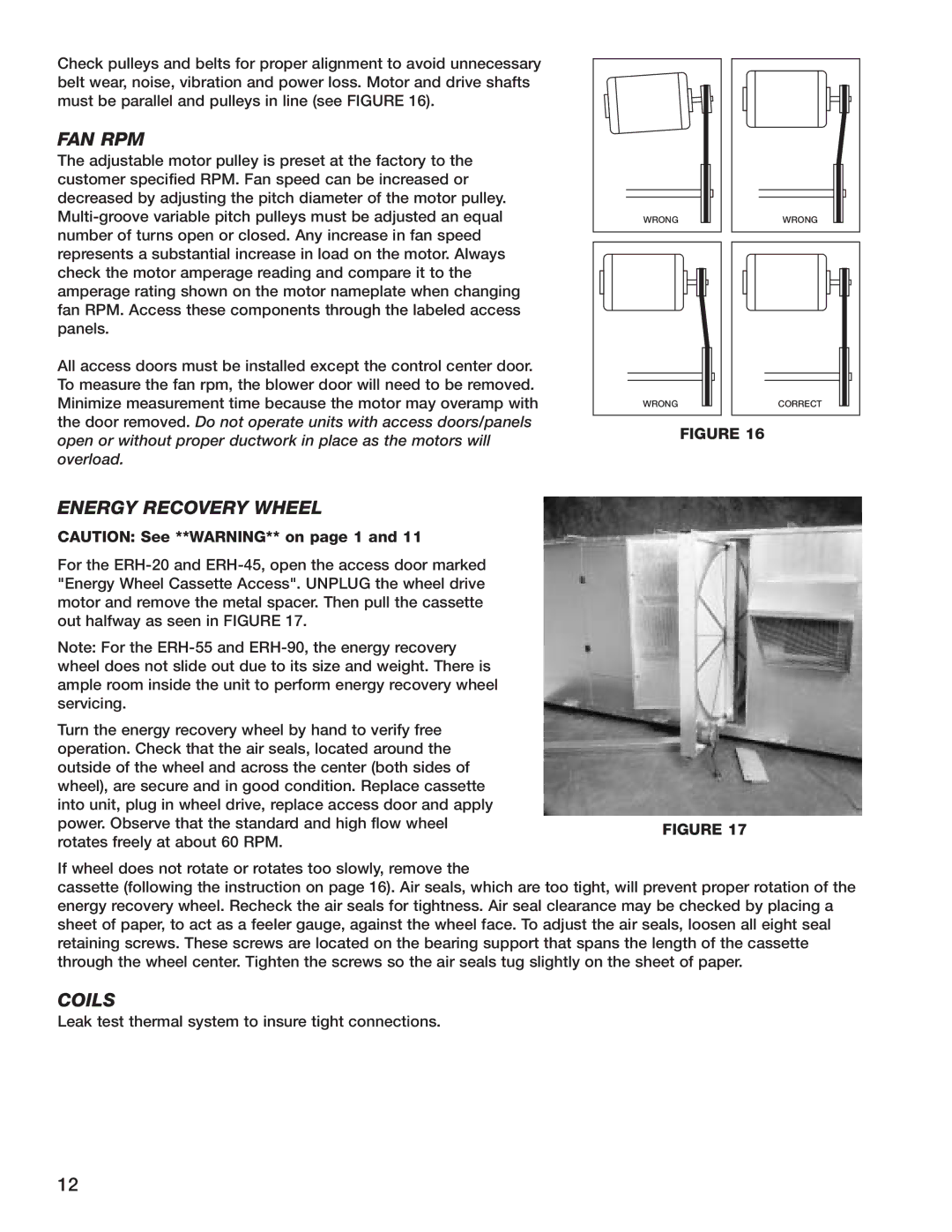

Check pulleys and belts for proper alignment to avoid unnecessary belt wear, noise, vibration and power loss. Motor and drive shafts must be parallel and pulleys in line (see FIGURE 16).

FAN RPM

The adjustable motor pulley is preset at the factory to the customer specified RPM. Fan speed can be increased or decreased by adjusting the pitch diameter of the motor pulley.

All access doors must be installed except the control center door. To measure the fan rpm, the blower door will need to be removed. Minimize measurement time because the motor may overamp with the door removed. Do not operate units with access doors/panels

WRONG |

WRONG |

WRONG |

CORRECT

open or without proper ductwork in place as the motors will overload.

FIGURE 16

ENERGY RECOVERY WHEEL

CAUTION: See **WARNING** on page 1 and 11

For the

Note: For the

Turn the energy recovery wheel by hand to verify free operation. Check that the air seals, located around the outside of the wheel and across the center (both sides of wheel), are secure and in good condition. Replace cassette into unit, plug in wheel drive, replace access door and apply

power. Observe that the standard and high flow wheelFIGURE 17 rotates freely at about 60 RPM.

If wheel does not rotate or rotates too slowly, remove the

cassette (following the instruction on page 16). Air seals, which are too tight, will prevent proper rotation of the energy recovery wheel. Recheck the air seals for tightness. Air seal clearance may be checked by placing a sheet of paper, to act as a feeler gauge, against the wheel face. To adjust the air seals, loosen all eight seal retaining screws. These screws are located on the bearing support that spans the length of the cassette through the wheel center. Tighten the screws so the air seals tug slightly on the sheet of paper.

COILS

Leak test thermal system to insure tight connections.

12