Installation Stages

Once the PVe Heat Recovery Ventilator is delivered to the jobsite, the actual installation occurs in several distinct stages.

1.Installation location must be carefully considered. Service clearances needed for later maintenance of the unit must be taken into consideration, access to Return Air and Discharge Air ducting must be anticipated. And structural support

of the unit must be taken into consideration. See appropriate sections of this manual for further information. If electric wiring is going to be brought into the cabinet from beneath (recommended), preparations for that step must be taken during the planning stage. If possible, a GKD curb should be installed prior to installation of roofing materials so that flashing can be run up the sides of the curb.

2.Hoisting the cabinet can be accomplished with either a crane or a fork lift. If a forklift is used, the forks must extend all the way through the cabinet and project from the far side. The forks should be padded with a layer of

If a crane is used, hoisting points are provided at each corner of the cabinet. Small, padded hooks must be inserted into the hoisting points. There is very little internal clearance inside the cabinet base and the use of large lifting hooks will either dig into the cabinet structure or else interfere with the seating of the cabinet on the GKD curb.

2. Physical installation of the unit should be |

completed prior to installation of electrical wiring. |

Condensate drains should be connected and if |

necessary, heat strips installed on the drains to |

prevent freezing of the traps. A final check should |

be made to ensure that the unit has been installed |

level by using the bottom of the cabinet as a |

reference, not the top (the cabinet roof is sloped |

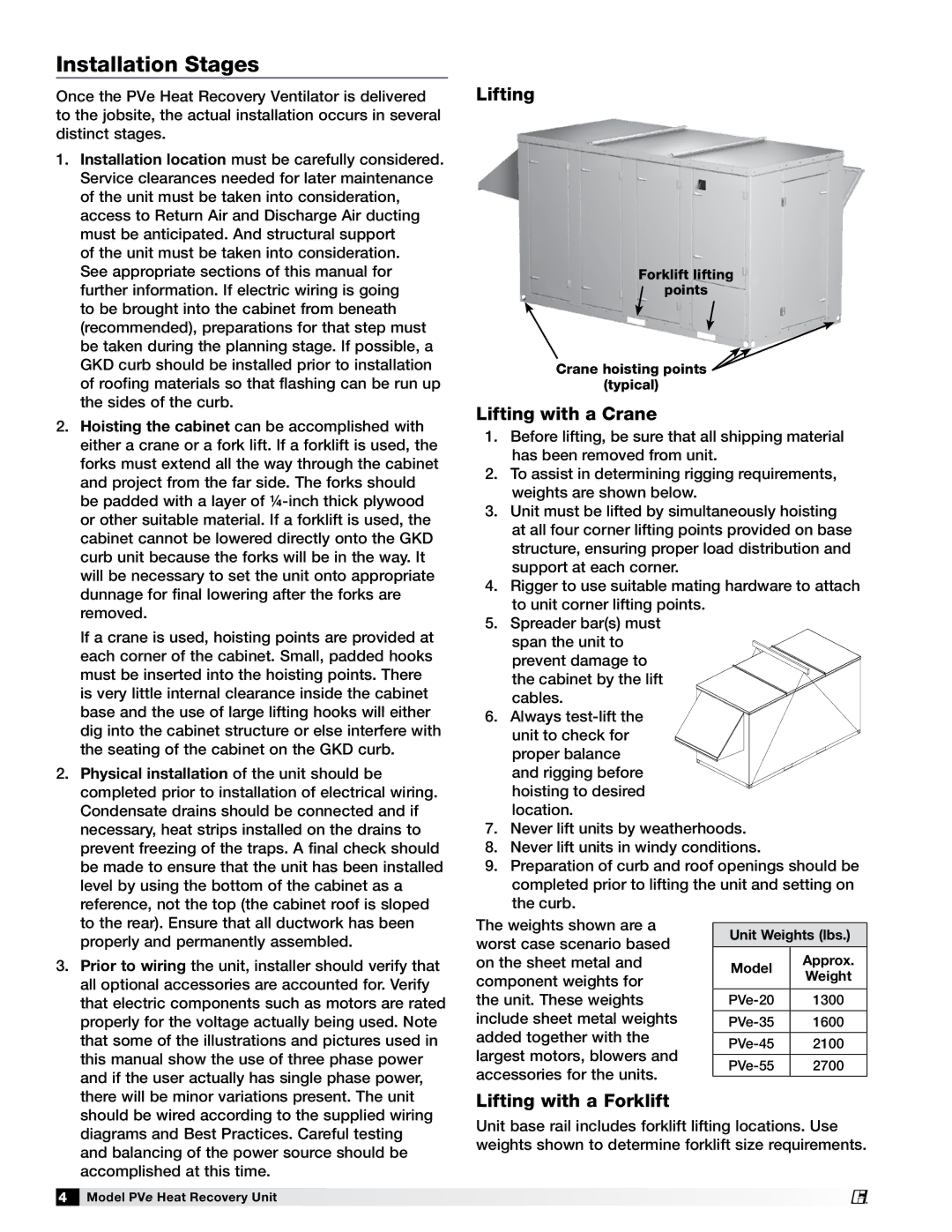

Lifting

Forklift lifting

points

Crane hoisting points ![]() (typical)

(typical)

Lifting with a Crane

1.Before lifting, be sure that all shipping material has been removed from unit.

2.To assist in determining rigging requirements, weights are shown below.

3.Unit must be lifted by simultaneously hoisting at all four corner lifting points provided on base structure, ensuring proper load distribution and support at each corner.

4.Rigger to use suitable mating hardware to attach to unit corner lifting points.

5.Spreader bar(s) must

span the unit to prevent damage to the cabinet by the lift cables.

6. Always

7.Never lift units by weatherhoods.

8.Never lift units in windy conditions.

9.Preparation of curb and roof openings should be completed prior to lifting the unit and setting on the curb.

to the rear). Ensure that all ductwork has been |

properly and permanently assembled. |

3. Prior to wiring the unit, installer should verify that |

all optional accessories are accounted for. Verify |

that electric components such as motors are rated |

properly for the voltage actually being used. Note |

that some of the illustrations and pictures used in |

this manual show the use of three phase power |

and if the user actually has single phase power, |

The weights shown are a worst case scenario based on the sheet metal and component weights for the unit. These weights include sheet metal weights added together with the largest motors, blowers and accessories for the units.

Unit Weights (lbs.)

Model | Approx. | |

Weight | ||

| ||

|

| |

1300 | ||

|

| |

1600 | ||

|

| |

2100 | ||

|

| |

2700 | ||

|

|

there will be minor variations present. The unit |

should be wired according to the supplied wiring |

diagrams and Best Practices. Careful testing |

and balancing of the power source should be |

accomplished at this time. |

4Model PVe Heat Recovery Unit

Lifting with a Forklift

Unit base rail includes forklift lifting locations. Use weights shown to determine forklift size requirements.