Routine Maintenance

Danger

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn the electrical power to unit to OFF at disconnect switch(es). Unit may have multiple power supplies.

CAUTION

Use caution when removing access panels or other unit components, especially while standing on a ladder or other potentially unsteady base. Access panels and unit components can be heavy and serious injury may occur.

Once the unit has been put into operation, a routine maintenance program should be set up to preserve reliability and performance. Items to be included in this program are:

Lubrication

Apply lubrication where required

Dampers

Check for unobstructed operation

Fan Belts

Check for wear, tension, alignment

Motors

Check for cleanliness

Blower Wheel & Fasteners

Check for cleanliness

Check all fasteners for tightness

Check for fatigue, corrosion, wear

Bearings

Check for cleanliness

Check set screws for tightness

Lubricate as required

External Filter

Check for cleanliness - clean if required

Internal Filter

Check for cleanliness - replace if required

Door Seal

Check if intact and pliable

Maintenance Procedures:

Lubrication

Check all moving components for proper lubrication. Apply lubrication where required. Any components showing excessive wear should be replaced to maintain the integrity of the unit and ensure proper operation.

Dampers

Check all dampers to ensure they open and close properly and without binding. Backdraft dampers can be checked by hand to determine if blades open and close freely. Apply power to motorized dampers to ensure the actuator opens and closes the damper as designed.

Fan Belts

Belts must be checked on a regular basis for wear, tension, alignment, and dirt accumulation. Premature or frequent belt failures can be caused by improper belt tension (either too loose or too tight) or misaligned sheaves. Abnormally high belt tension or drive misalignment will cause excessive bearing loads and may result in failure of the fan and/or motor bearings. Conversely, loose belts will cause squealing on

When replacing belts on multiple groove drives, all belts should be changed to provide uniform drive loading. Do not pry belts on or off the sheave. Loosen belt tension until belts can be removed by simply lifting the belts off the sheaves. After replacing belts, insure that slack in each belt is on the same side of the drive. Belt dressing should never be used.

Do not install new belts on worn sheaves. If the sheaves have grooves worn in them, they must be replaced before new belts are installed.

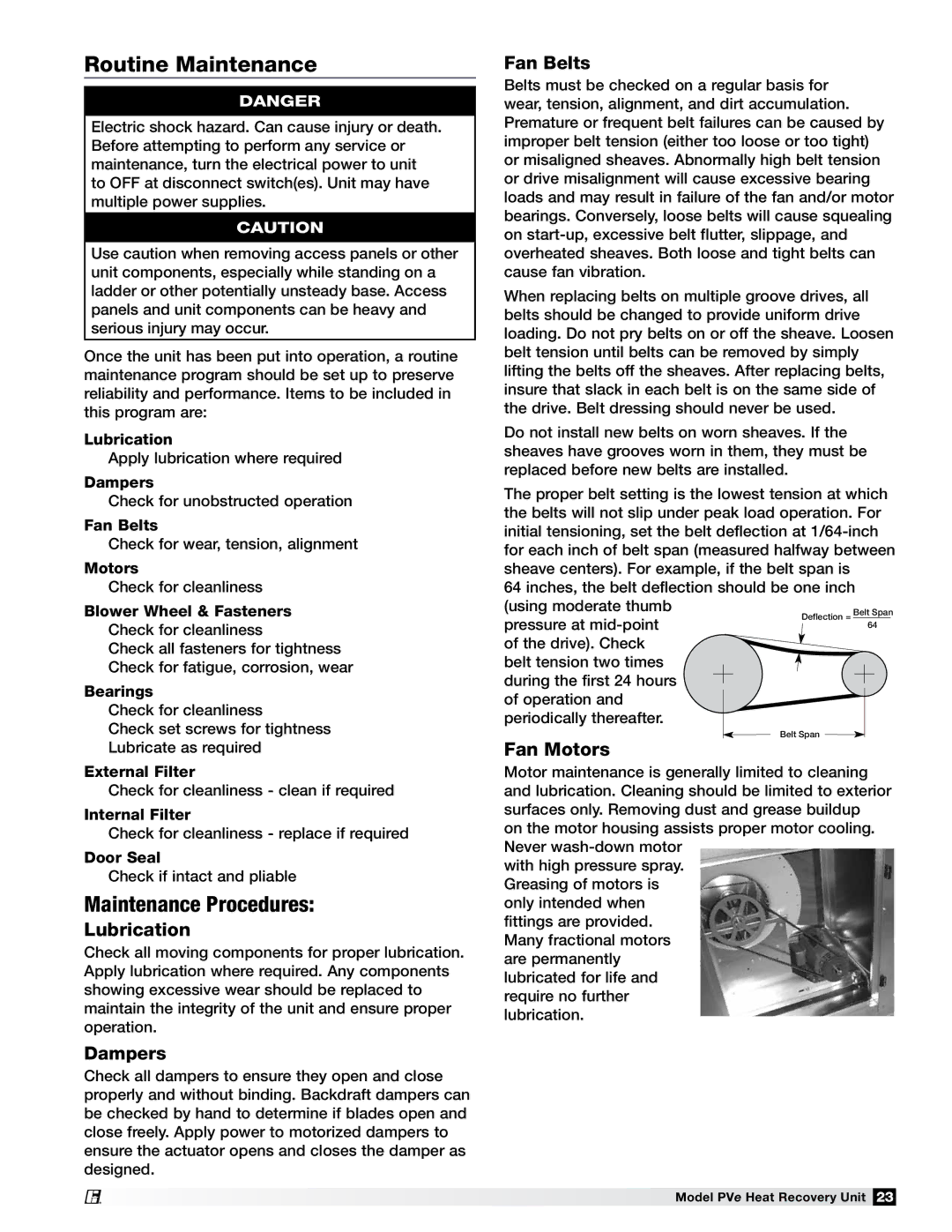

The proper belt setting is the lowest tension at which the belts will not slip under peak load operation. For initial tensioning, set the belt deflection at 1/64‑inch for each inch of belt span (measured halfway between sheave centers). For example, if the belt span is

64 inches, the belt deflection should be one inch (using moderate thumb

pressure at

of the drive). Check belt tension two times during the first 24 hours

of operation and periodically thereafter.

Belt Span

Fan Motors

Motor maintenance is generally limited to cleaning and lubrication. Cleaning should be limited to exterior surfaces only. Removing dust and grease buildup on the motor housing assists proper motor cooling. Never

with high pressure spray. Greasing of motors is only intended when fittings are provided. Many fractional motors are permanently lubricated for life and require no further lubrication.

Model PVe Heat Recovery Unit 23