TOOL REST (60)

EXTENSION TOOL REST

(58)

|

|

|

| HANDLE ASSY. |

| HANDLE ASSY. | (57) | ||

|

| |||

TOOL |

| (57) |

|

|

|

| |||

|

|

|

| |

REST |

|

|

| FIGURE M |

BODY |

|

|

| |

(56) |

|

| HANDLE ASSY. | |

|

| |||

|

|

|

| (57) |

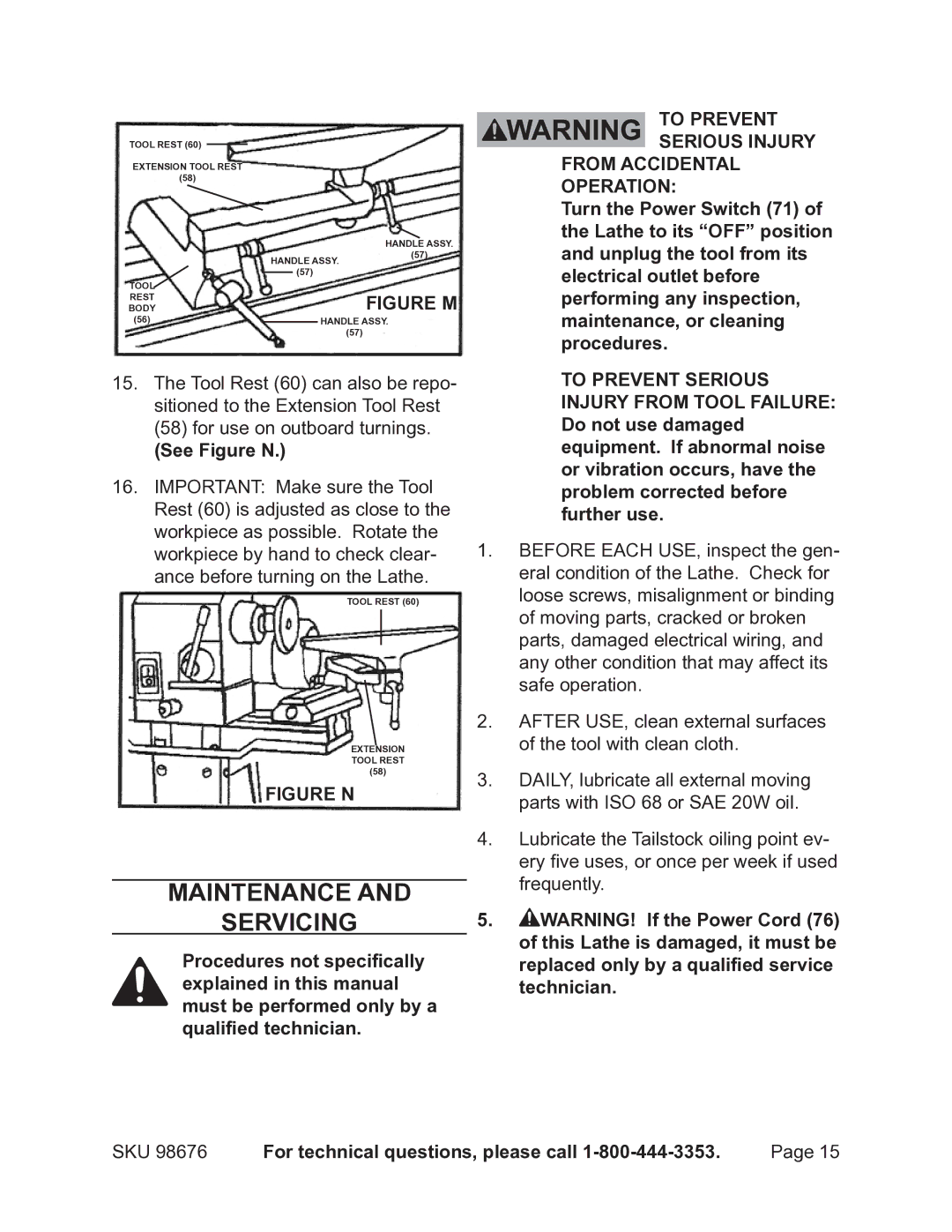

15.The Tool Rest (60) can also be repo- sitioned to the Extension Tool Rest (58) for use on outboard turnings.

(See Figure N.)

16.IMPORTANT: Make sure the Tool Rest (60) is adjusted as close to the workpiece as possible. Rotate the workpiece by hand to check clear- ance before turning on the Lathe.

TOOL REST (60)

EXTENSION TOOL REST (58)

FIGURE N

Maintenance And

Servicing

Procedures not specifically explained in this manual must be performed only by a qualified technician.

To prevent serious injury

from accidental operation:

Turn the Power Switch (71) of the Lathe to its “OFF” position and unplug the tool from its electrical outlet before performing any inspection, maintenance, or cleaning procedures.

To prevent serious injury from tool failure: Do not use damaged equipment. If abnormal noise or vibration occurs, have the problem corrected before further use.

1.BEFORE EACH USE, inspect the gen- eral condition of the Lathe. Check for loose screws, misalignment or binding of moving parts, cracked or broken parts, damaged electrical wiring, and any other condition that may affect its safe operation.

2.After Use, clean external surfaces of the tool with clean cloth.

3.DAILY, lubricate all external moving parts with ISO 68 or SAE 20W oil.

4.Lubricate the Tailstock oiling point ev- ery five uses, or once per week if used frequently.

5.![]() WARNING! If the Power Cord (76) of this Lathe is damaged, it must be replaced only by a qualified service technician.

WARNING! If the Power Cord (76) of this Lathe is damaged, it must be replaced only by a qualified service technician.

SKU 98676 | For technical questions, please call | Page 15 |