Depth Of Cut

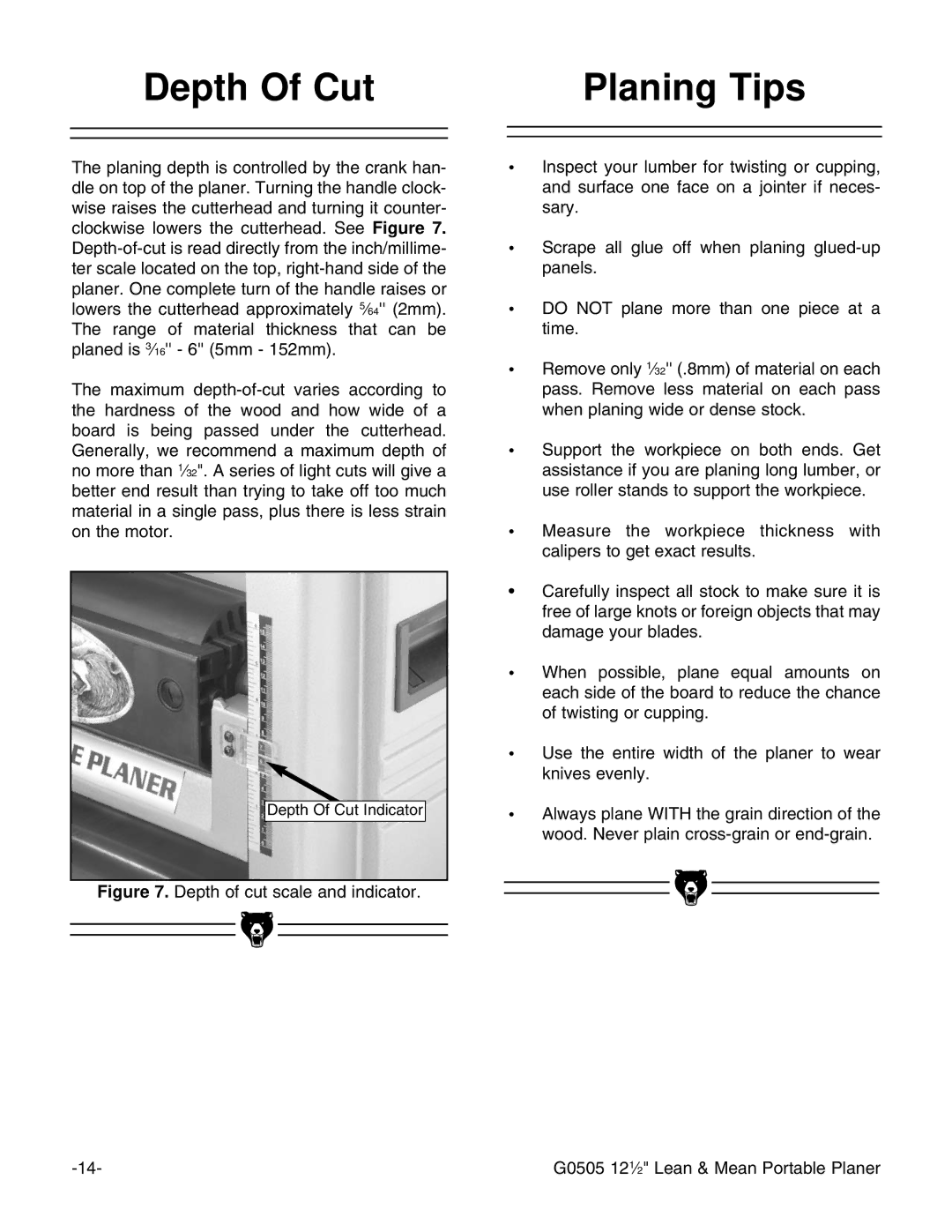

The planing depth is controlled by the crank han- dle on top of the planer. Turning the handle clock- wise raises the cutterhead and turning it counter- clockwise lowers the cutterhead. See Figure 7.

The maximum

Depth Of Cut Indicator

Figure 7. Depth of cut scale and indicator.

Planing Tips

•Inspect your lumber for twisting or cupping, and surface one face on a jointer if neces- sary.

•Scrape all glue off when planing

•DO NOT plane more than one piece at a time.

•Remove only 1⁄32'' (.8mm) of material on each pass. Remove less material on each pass when planing wide or dense stock.

•Support the workpiece on both ends. Get assistance if you are planing long lumber, or use roller stands to support the workpiece.

•Measure the workpiece thickness with calipers to get exact results.

•Carefully inspect all stock to make sure it is free of large knots or foreign objects that may damage your blades.

•When possible, plane equal amounts on each side of the board to reduce the chance of twisting or cupping.

•Use the entire width of the planer to wear knives evenly.

•Always plane WITH the grain direction of the wood. Never plain

|

|

|

|

|

|

|

|

|

| G0505 121⁄2" Lean & Mean Portable Planer | |

|

|