Wood Types |

| Wood Characteristics |

|

|

|

|

|

|

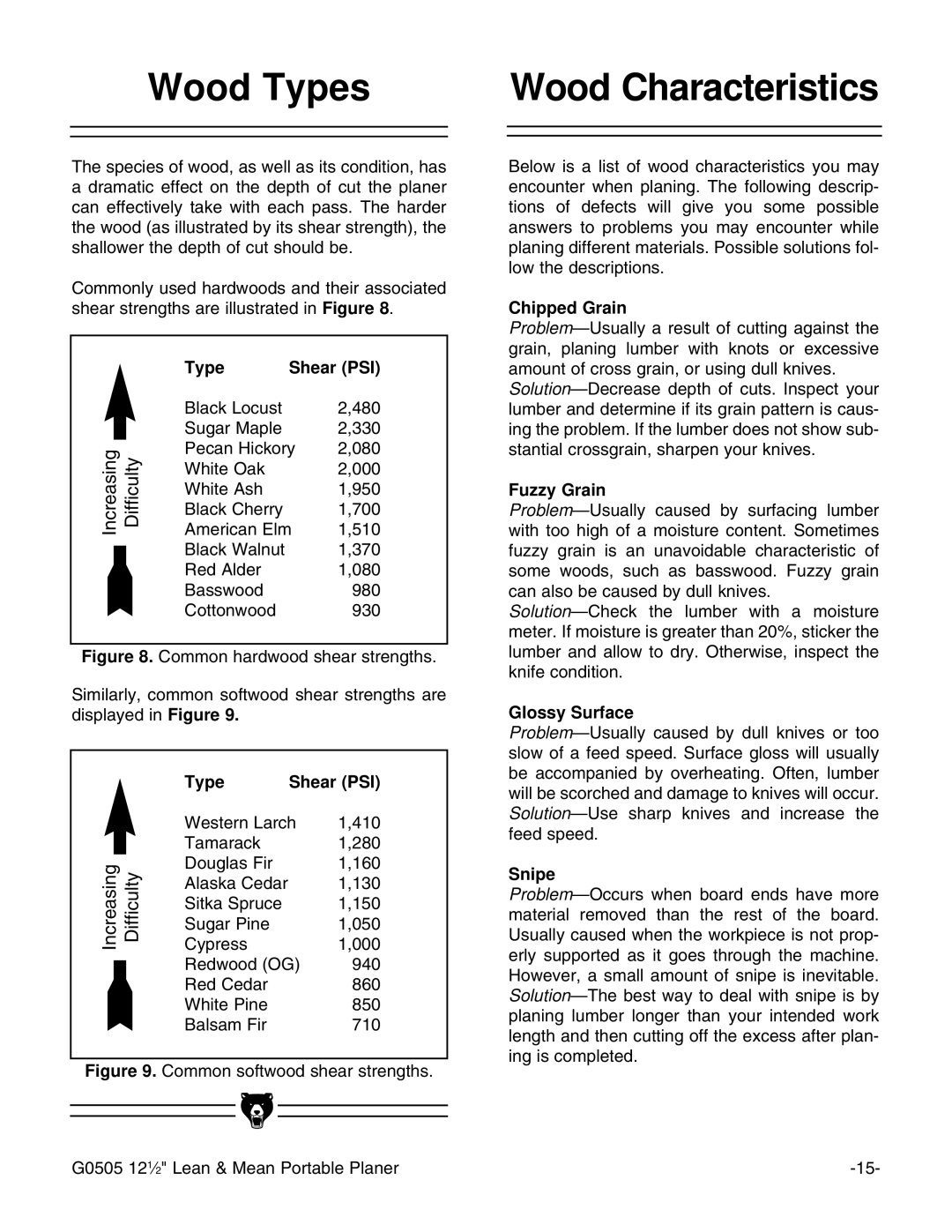

The species of wood, as well as its condition, has a dramatic effect on the depth of cut the planer can effectively take with each pass. The harder the wood (as illustrated by its shear strength), the shallower the depth of cut should be.

Commonly used hardwoods and their associated shear strengths are illustrated in Figure 8.

|

|

|

|

| Type | Shear (PSI) |

| |

|

|

|

|

| Black Locust |

| 2,480 |

|

|

|

|

|

|

|

| ||

|

|

|

|

| Sugar Maple |

| 2,330 |

|

| Increasing Difficulty |

| Pecan Hickory | 2,080 |

| |||

|

| American Elm | 1,510 |

| ||||

|

|

|

|

| White Oak |

| 2,000 |

|

|

|

|

|

| White Ash |

| 1,950 |

|

|

|

|

|

| Black Cherry |

| 1,700 |

|

|

|

|

|

| Black Walnut |

| 1,370 |

|

|

|

|

|

|

|

| ||

|

|

|

|

| Red Alder |

| 1,080 |

|

|

|

|

|

|

|

| ||

|

|

|

|

| Basswood |

| 980 |

|

|

|

|

|

| Cottonwood |

| 930 |

|

|

|

|

|

|

|

|

|

|

Figure 8. Common hardwood shear strengths.

Similarly, common softwood shear strengths are displayed in Figure 9.

|

|

|

|

| Type | Shear (PSI) |

| |

|

|

|

|

| Western Larch | 1,410 |

| |

|

|

|

|

|

| |||

|

|

|

|

| Tamarack |

| 1,280 |

|

| Increasing Difficulty |

| Douglas Fir |

| 1,160 |

| ||

|

| Cypress |

| 1,000 |

| |||

|

|

|

|

| Alaska Cedar |

| 1,130 |

|

|

|

|

|

| Sitka Spruce |

| 1,150 |

|

|

|

|

|

| Sugar Pine |

| 1,050 |

|

|

|

|

|

| Redwood (OG) | 940 |

| |

|

|

|

|

|

| |||

|

|

|

|

| Red Cedar |

| 860 |

|

|

|

|

|

|

|

| ||

|

|

|

|

| White Pine |

| 850 |

|

|

|

|

|

| Balsam Fir |

| 710 |

|

|

|

|

|

|

|

|

|

|

Figure 9. Common softwood shear strengths.

Below is a list of wood characteristics you may encounter when planing. The following descrip- tions of defects will give you some possible answers to problems you may encounter while planing different materials. Possible solutions fol- low the descriptions.

Chipped Grain

Fuzzy Grain

Glossy Surface

Snipe

|

|

| |

|

|

| |

|

|

| |

G0505 121⁄2" Lean & Mean Portable Planer | |||