Calculating Spindle

Speed

Closely follow the proper spindle speed and proper feed rate to produce good results, reduce undue strain on all moving parts and increase operator safety.

Prior to milling, determine the spindle speed needed to cut your workpiece, then set the speed on the machine.

To determine the needed spindle speed:

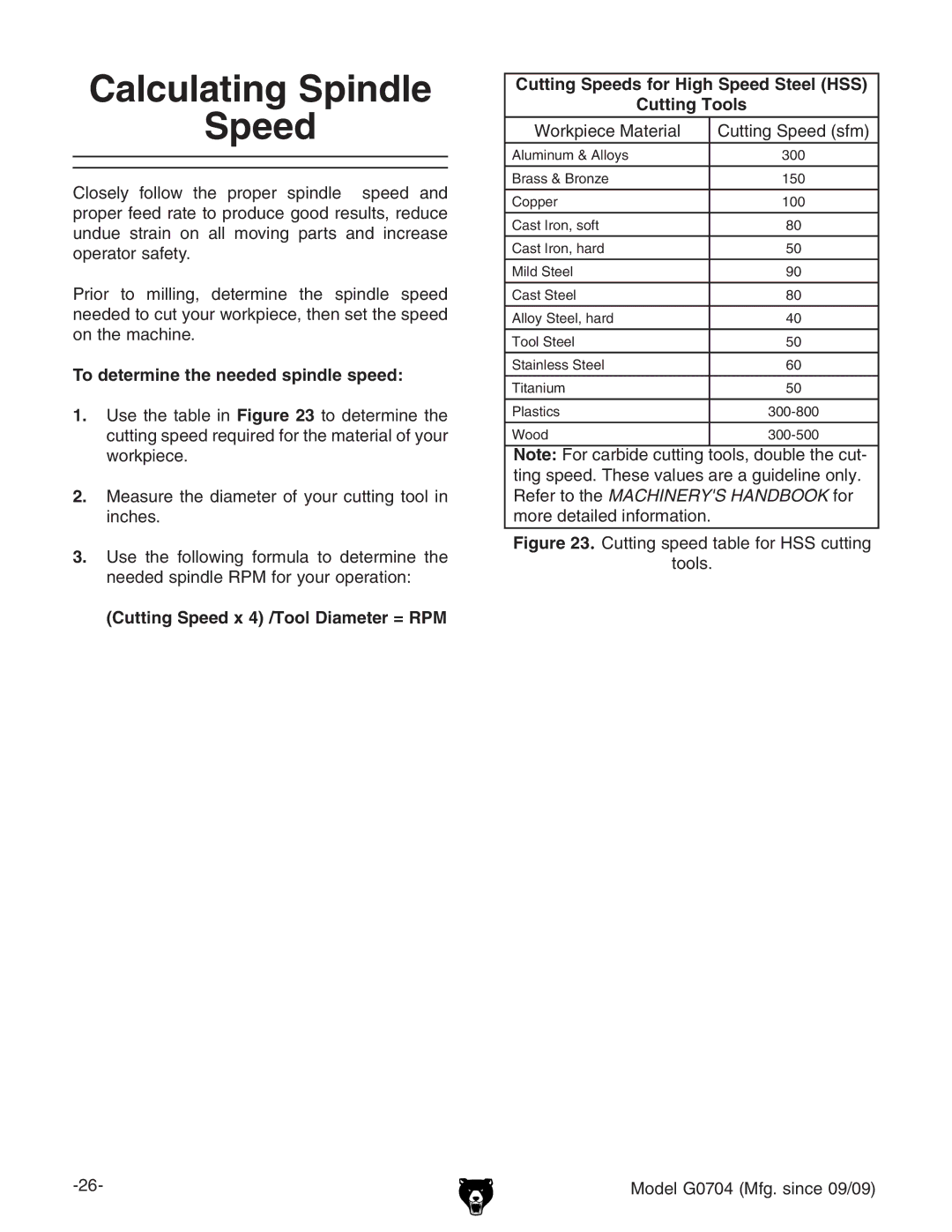

1.Use the table in Figure 23 to determine the cutting speed required for the material of your workpiece.

2.Measure the diameter of your cutting tool in inches.

3.Use the following formula to determine the needed spindle RPM for your operation:

(Cutting Speed x 4) /Tool Diameter = RPM

Cutting Speeds for High Speed Steel (HSS)

Cutting Tools

Workpiece Material | Cutting Speed (sfm) |

|

|

Aluminum & Alloys | 300 |

|

|

Brass & Bronze | 150 |

|

|

Copper | 100 |

|

|

Cast Iron, soft | 80 |

|

|

Cast Iron, hard | 50 |

|

|

Mild Steel | 90 |

|

|

Cast Steel | 80 |

|

|

Alloy Steel, hard | 40 |

|

|

Tool Steel | 50 |

|

|

Stainless Steel | 60 |

|

|

Titanium | 50 |

|

|

Plastics | |

|

|

Wood |

Note: For carbide cutting tools, double the cut- ting speed. These values are a guideline only. Refer to the MACHINERY'S HANDBOOK for more detailed information.