5.Raise the die up close to the hammer by moving the die housing lever to the left.

Figure 11. Raising the die up closer to the

hammer using the die housing lever.

6.(Optional) Remove the plug (part #28) from the C-frame, and use a funnel or other tool to pour sand into the frame. Replace plug when complete.

7.Place 8-10 drops of pneumatic tool oil into the air fitting on the foot switch and another 8-10 drops in the air fitting installed in the ham- mer assembly. This is more than the usual amount of lubrication you will use during maintenance. The purpose of this is to "load up" the pneumatic components when they are new.

8.Connect the air supply to the hose coming out of the foot switch (see Figure ??).

Note: There are many different styles of quick connect fittings. If the air fitting supplied with the Model G0711 does not fit the style you have on your hose, you will need to make them match.

9.Place the foot switch on the floor, then posi- tion it in a comfortable operating position.

10.Adjust the air pressure to 50 PSI.

11.If you have not already done so, put on your safety glasses and hearing protection now.

12.Test the operation of the planishing ham- mer by briefly pushing and releasing the foot switch. The hammer should actuate.

—If the hammer DOES actuate, the machine is operating correctly and you are finished with the Assembly & Setup.

—If the hammer DOES NOT actuate, adjust the air pressure up 20 PSI, then test the foot switch again. If the hammer still DOES NOT actuate after this test, adjust the speed adjustment knob on the planishing hammer assembly (Figure 12) and try again.

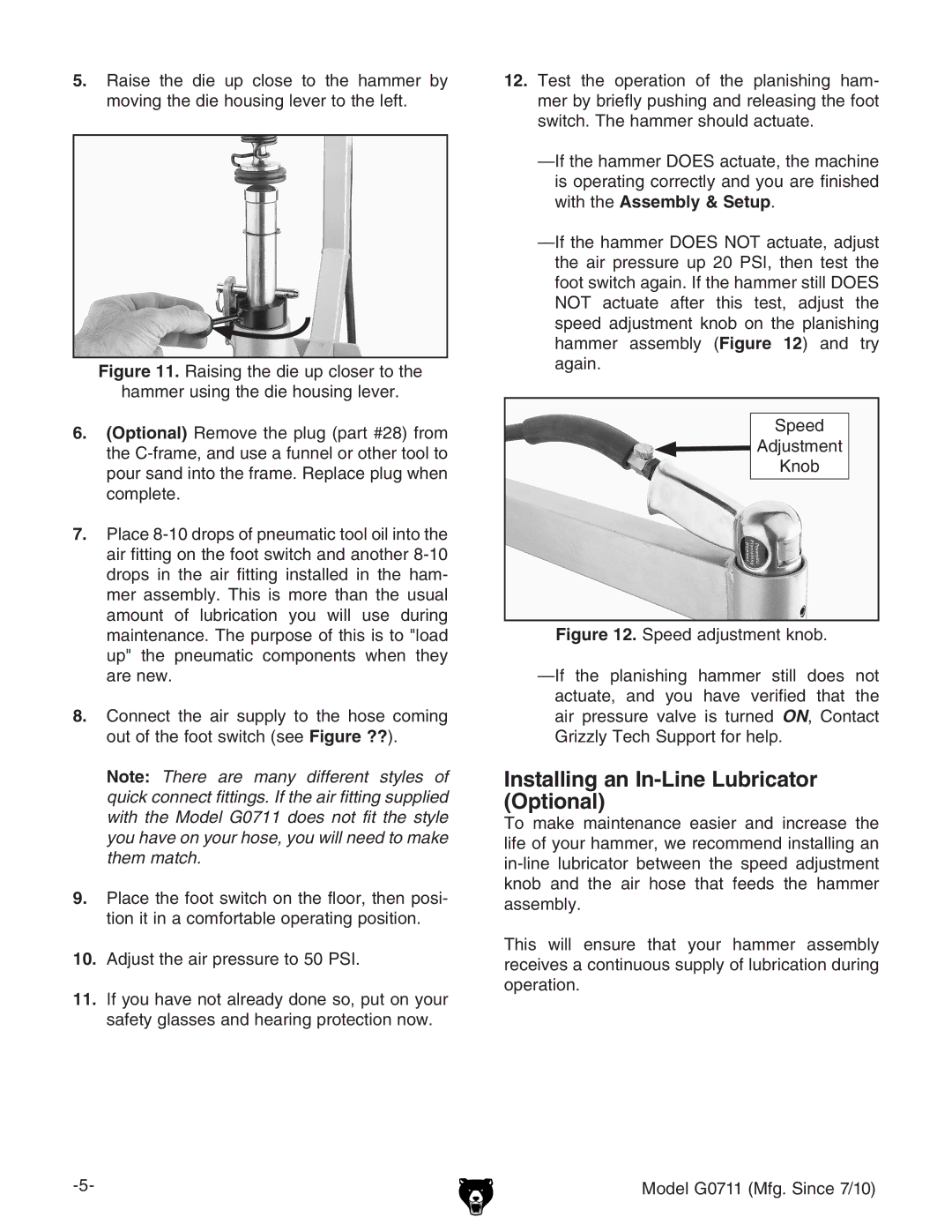

Speed

Adjustment

Adjustment

Knob

Figure 12. Speed adjustment knob.

—If the planishing hammer still does not actuate, and you have verified that the air pressure valve is turned ON, Contact Grizzly Tech Support for help.

Installing an In-Line Lubricator (Optional)

To make maintenance easier and increase the life of your hammer, we recommend installing an

This will ensure that your hammer assembly receives a continuous supply of lubrication during operation.