Dado Cutting

Commonly used in furniture joinery, a dado is a straight channel cut in the face of the workpiece. Dadoes can be cut using either a dado blade (Figure 28) or a standard saw blade.

Dado operations present very real hazards requiring proper procedures to avoid seri- ous injury. The chance of kickback is always greater when dado blades are used so extra care must be taken. Any movement of the stock away from the fence will cause kickback. Be certain that stock is flat and straight. Failure to follow these warnings could result in serious personal injury.

To use a stacked or wobble dado blade:

1.Disconnect the machine from the power source!

2.Remove the table insert, splitter guard, and regular saw blade.

3.Attach and adjust the dado blade system as recommended in the dado blade manufac- turerÕs instructions.

4.Install the dado table insert.

5.Raise the dado blade up to the desired depth of cut (depth of dado channel desired).

Never perform a through cut operation with a dado blade. A dado blade was designed to make

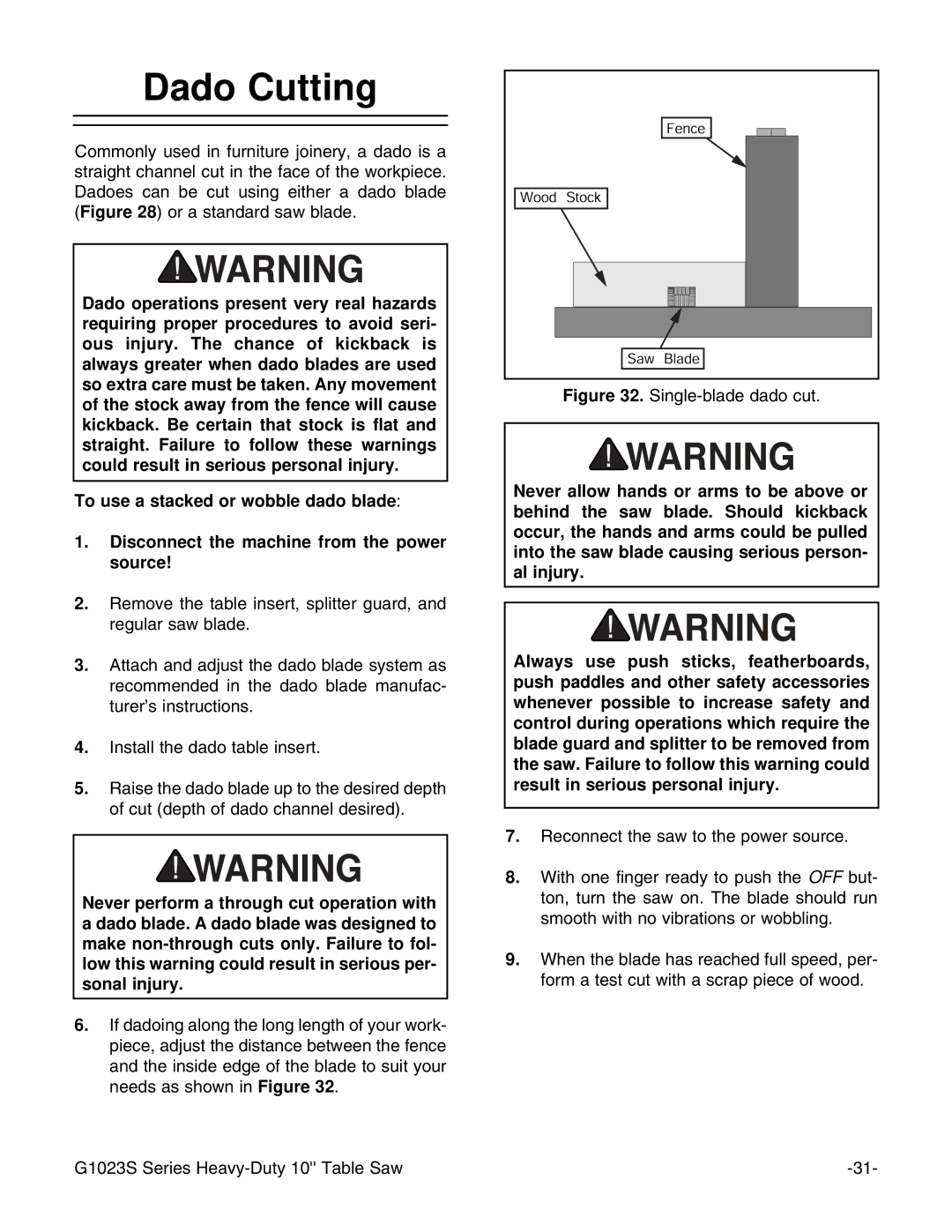

6.If dadoing along the long length of your work- piece, adjust the distance between the fence and the inside edge of the blade to suit your needs as shown in Figure 32.

Figure 32. Single-blade dado cut.

Never allow hands or arms to be above or behind the saw blade. Should kickback occur, the hands and arms could be pulled into the saw blade causing serious person- al injury.

Always use push sticks, featherboards, push paddles and other safety accessories whenever possible to increase safety and control during operations which require the blade guard and splitter to be removed from the saw. Failure to follow this warning could result in serious personal injury.

7.Reconnect the saw to the power source.

8.With one finger ready to push the OFF but- ton, turn the saw on. The blade should run smooth with no vibrations or wobbling.

9.When the blade has reached full speed, per- form a test cut with a scrap piece of wood.

G1023S Series |