Wear safety glasses. a dust mask, and hearing protection while the machine is running. Failure to do this could result in serious personal injury.

Blade Selection

Choosing the correct blade for the job is essential for the safe and efficient use of your table saw.

Rip Blade: Used for cutting with the grain. 10" rip blades have between 20-40 teeth (Figure 24), flat-top ground tooth profile (Figure 29) and large gullets to allow for large chip removal.

Figure 24. Ripping blade.

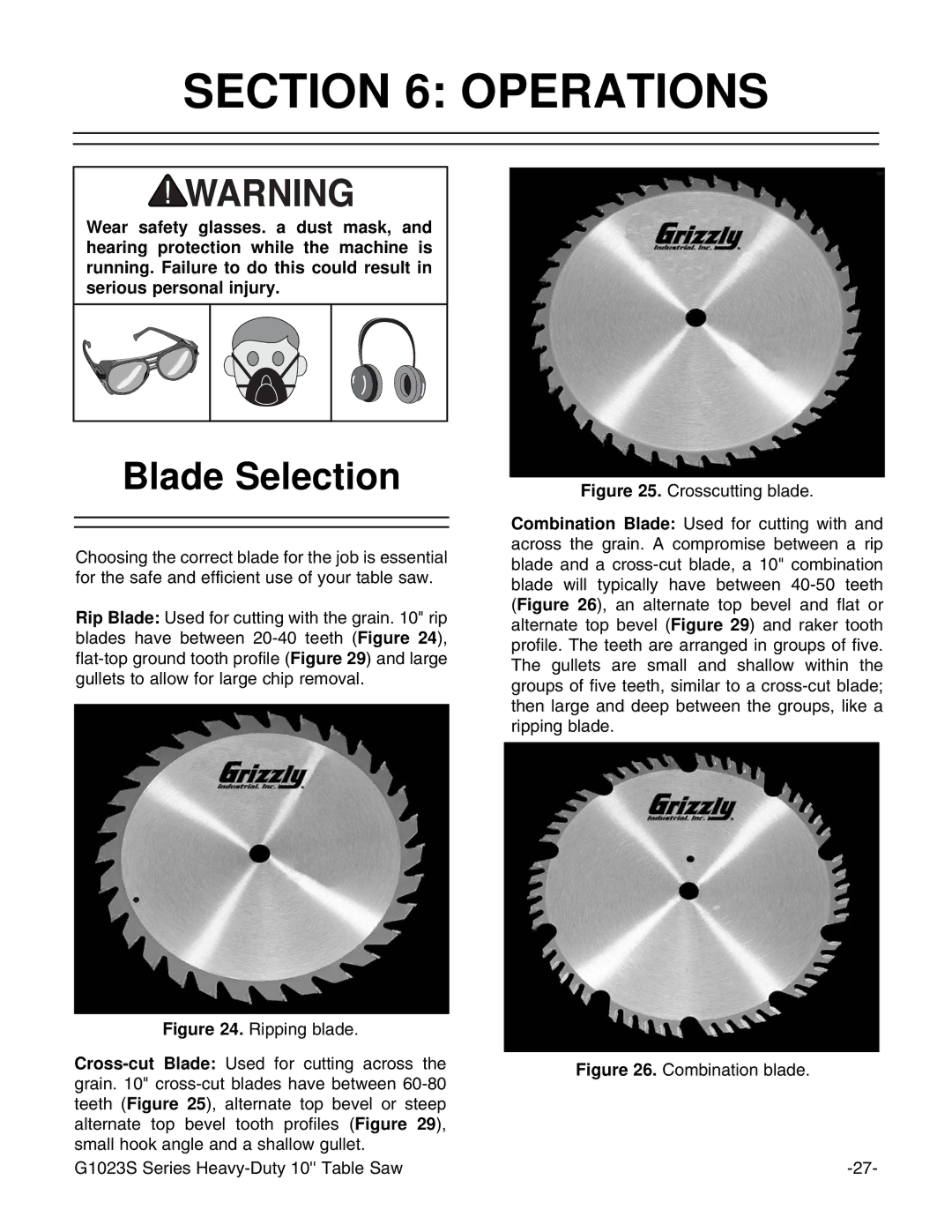

Cross-cut Blade: Used for cutting across the grain. 10" cross-cut blades have between 60-80 teeth (Figure 25), alternate top bevel or steep alternate top bevel tooth profiles (Figure 29), small hook angle and a shallow gullet.

G1023S Series Heavy-Duty 10'' Table Saw