2.Turn the crank clockwise to feed the workpiece

until its edge is directly above the rear roller, as shown in Figure 18.

This machine poses a crushing hazard if workpieces are not properly supported when exiting the rollers. If necessary, get assistance to support the workpiece. Make sure all helpers are wearing safety glasses, leather gloves, and steel toed footwear when assisting in the use of this machine.

Figure 18. Feeding the workpiece.

3.Turn the radius adjust knobs to lift the rear roller until the desired radius bend is reached (Figure 19). Make sure to turn the knobs equal amounts so the rear roller is always parallel with the other rollers. Failure to do so will create a larger radius on one end than the other, resulting in a cone or spiral shape.

8L

Figure 19. Setting the radius.

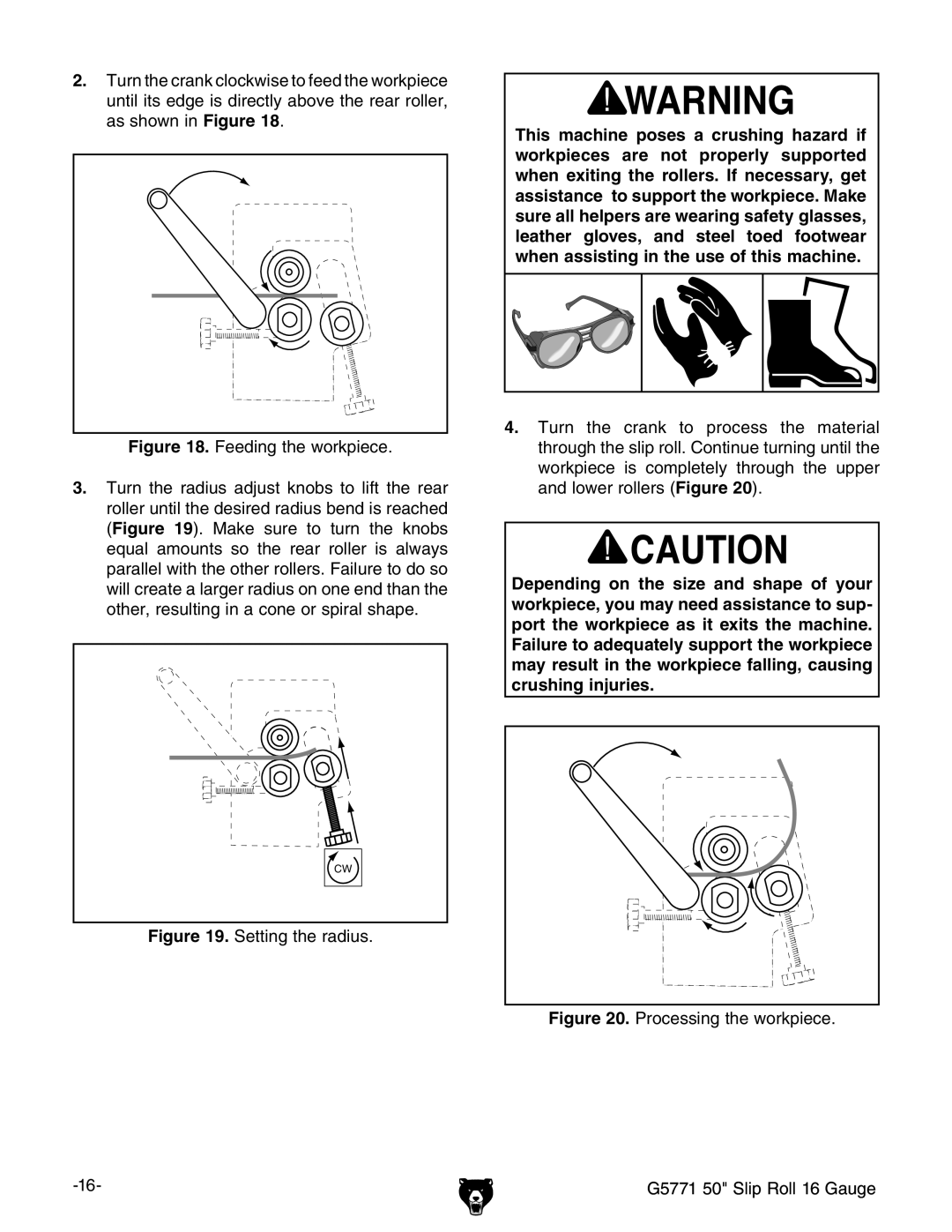

4.Turn the crank to process the material through the slip roll. Continue turning until the workpiece is completely through the upper and lower rollers (Figure 20).

Depending on the size and shape of your workpiece, you may need assistance to sup- port the workpiece as it exits the machine. Failure to adequately support the workpiece may result in the workpiece falling, causing crushing injuries.