Miter Gauge

The miter gauge needs to be adjusted perpendic- ular to the face of the wheel when it is mounted in the table slot.

To adjust miter gauge:

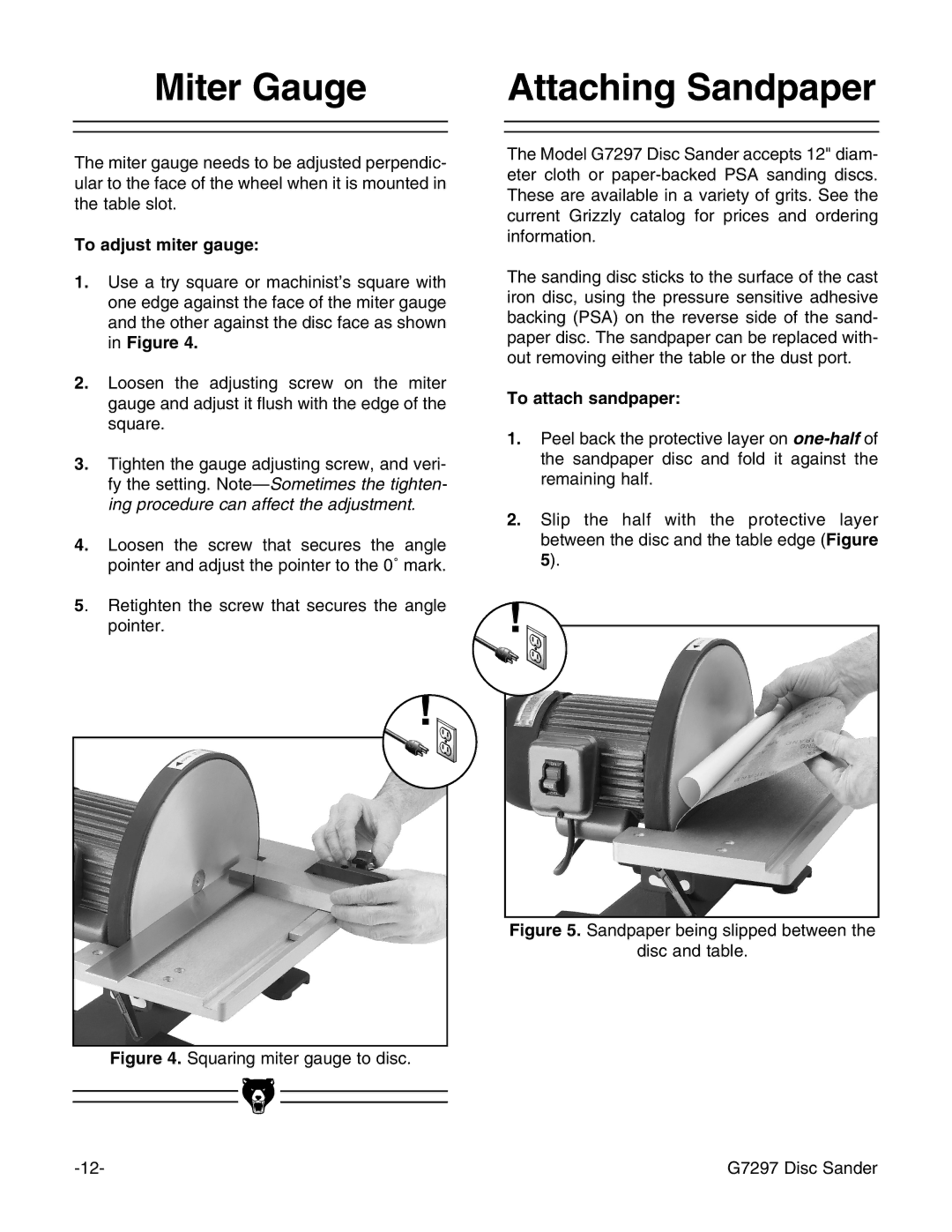

1.Use a try square or machinist’s square with one edge against the face of the miter gauge and the other against the disc face as shown in Figure 4.

2.Loosen the adjusting screw on the miter gauge and adjust it flush with the edge of the square.

3.Tighten the gauge adjusting screw, and veri- fy the setting.

4.Loosen the screw that secures the angle pointer and adjust the pointer to the 0˚ mark.

5. Retighten the screw that secures the angle pointer.

Figure 4. Squaring miter gauge to disc.

Attaching Sandpaper

The Model G7297 Disc Sander accepts 12" diam- eter cloth or

The sanding disc sticks to the surface of the cast iron disc, using the pressure sensitive adhesive backing (PSA) on the reverse side of the sand- paper disc. The sandpaper can be replaced with- out removing either the table or the dust port.

To attach sandpaper:

1.Peel back the protective layer on

2.Slip the half with the protective layer between the disc and the table edge (Figure 5).

Figure 5. Sandpaper being slipped between the

disc and table.

|

|

| G7297 Disc Sander |

|

|

| |

|

| ||

|

|