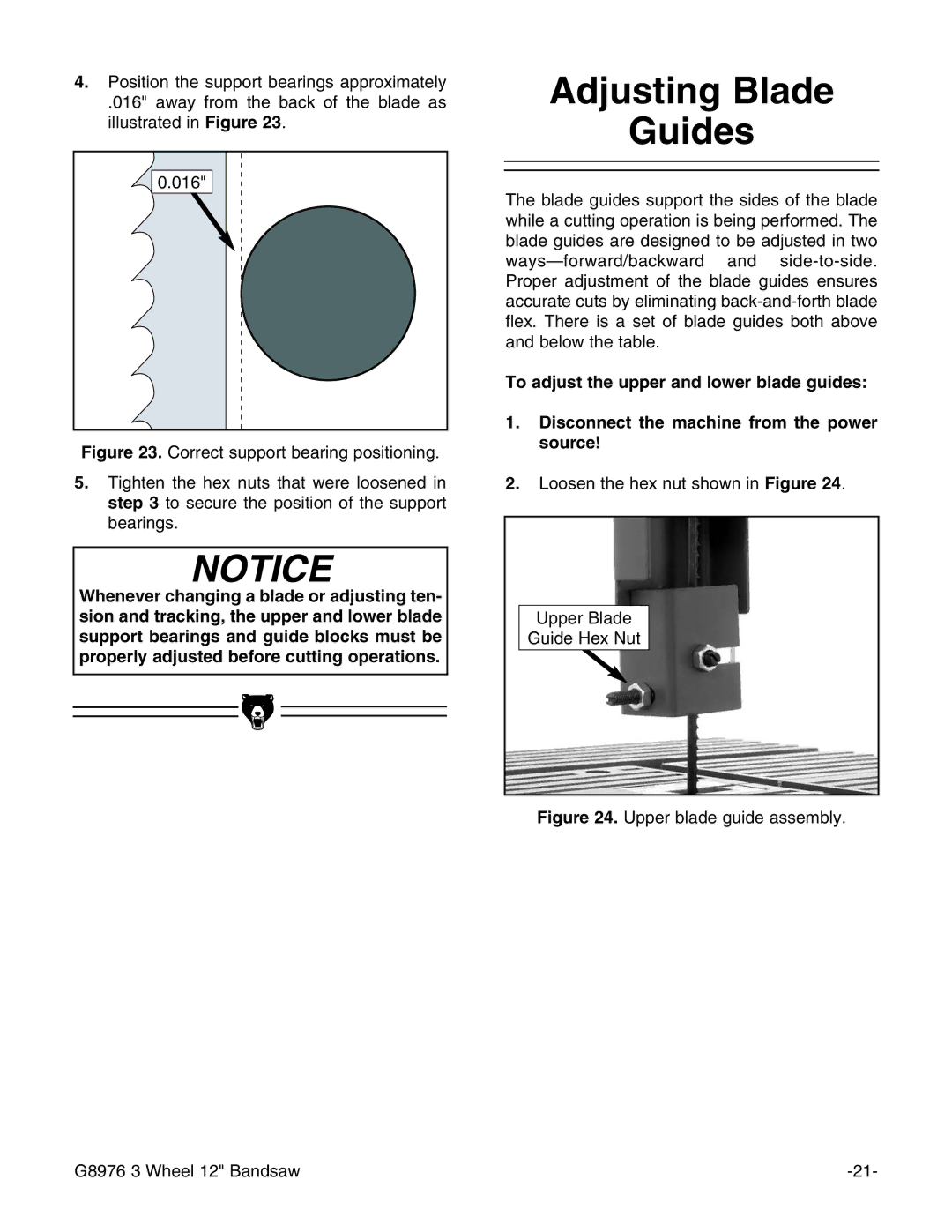

4.Position the support bearings approximately

.016" away from the back of the blade as illustrated in Figure 23.

0.016"

Figure 23. Correct support bearing positioning.

5.Tighten the hex nuts that were loosened in step 3 to secure the position of the support bearings.

NOTICE

Whenever changing a blade or adjusting ten- sion and tracking, the upper and lower blade support bearings and guide blocks must be properly adjusted before cutting operations.

Adjusting Blade

Guides

The blade guides support the sides of the blade while a cutting operation is being performed. The blade guides are designed to be adjusted in two

To adjust the upper and lower blade guides:

1.Disconnect the machine from the power source!

2.Loosen the hex nut shown in Figure 24.

Upper Blade

Guide Hex Nut

Figure 24. Upper blade guide assembly.

G8976 3 Wheel 12" Bandsaw |