Mounting to Shop

Floor

The bandsaw center of gravity is above the middle of the machine. Although not required, we strong- ly recommend that you mount your new machine to the floor to prevent tipping. Because this is an optional step and floor materials may vary, floor mounting hardware is not included.

Bolting to Concrete Floors

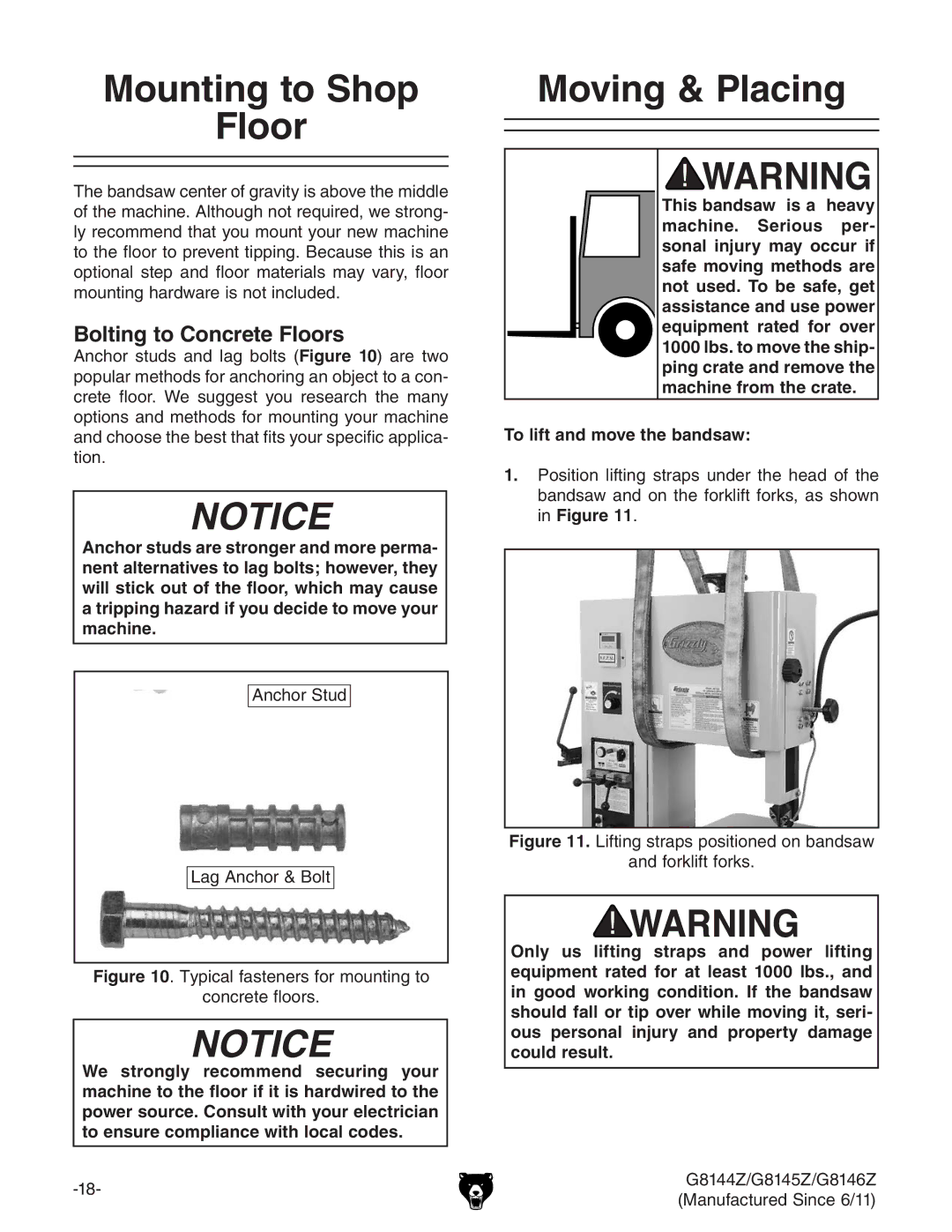

Anchor studs and lag bolts (Figure 10) are two popular methods for anchoring an object to a con- crete floor. We suggest you research the many options and methods for mounting your machine and choose the best that fits your specific applica- tion.

NOTICE

Anchor studs are stronger and more perma- nent alternatives to lag bolts; however, they will stick out of the floor, which may cause a tripping hazard if you decide to move your machine.

Anchor Stud

Lag Anchor & Bolt

Figure 10. Typical fasteners for mounting to

concrete floors.

NOTICE

We strongly recommend securing your machine to the floor if it is hardwired to the power source. Consult with your electrician to ensure compliance with local codes.

Moving & Placing

This bandsaw is a heavy machine. Serious per- sonal injury may occur if safe moving methods are not used. To be safe, get assistance and use power equipment rated for over 1000 lbs. to move the ship- ping crate and remove the machine from the crate.

To lift and move the bandsaw:

1.Position lifting straps under the head of the bandsaw and on the forklift forks, as shown in Figure 11.

Figure 11. Lifting straps positioned on bandsaw

and forklift forks.

Only us lifting straps and power lifting equipment rated for at least 1000 lbs., and in good working condition. If the bandsaw should fall or tip over while moving it, seri- ous personal injury and property damage could result.

G8144Z/G8145Z/G8146Z (Manufactured Since 6/11)