checking coplanarity

Checking Wheel Coplanarity

1.DISCONNECT BANDSAW FROM POWER!

2.Remove the table assembly from the machine.

3.Make sure the blade is correctly installed and tensioned.

4.Hold a

Note: The upper wheel of the Model G8146Z can also be adjusted. To do this, refer to the detailed instructions later in this subsection.

Adjusting Lower Wheel

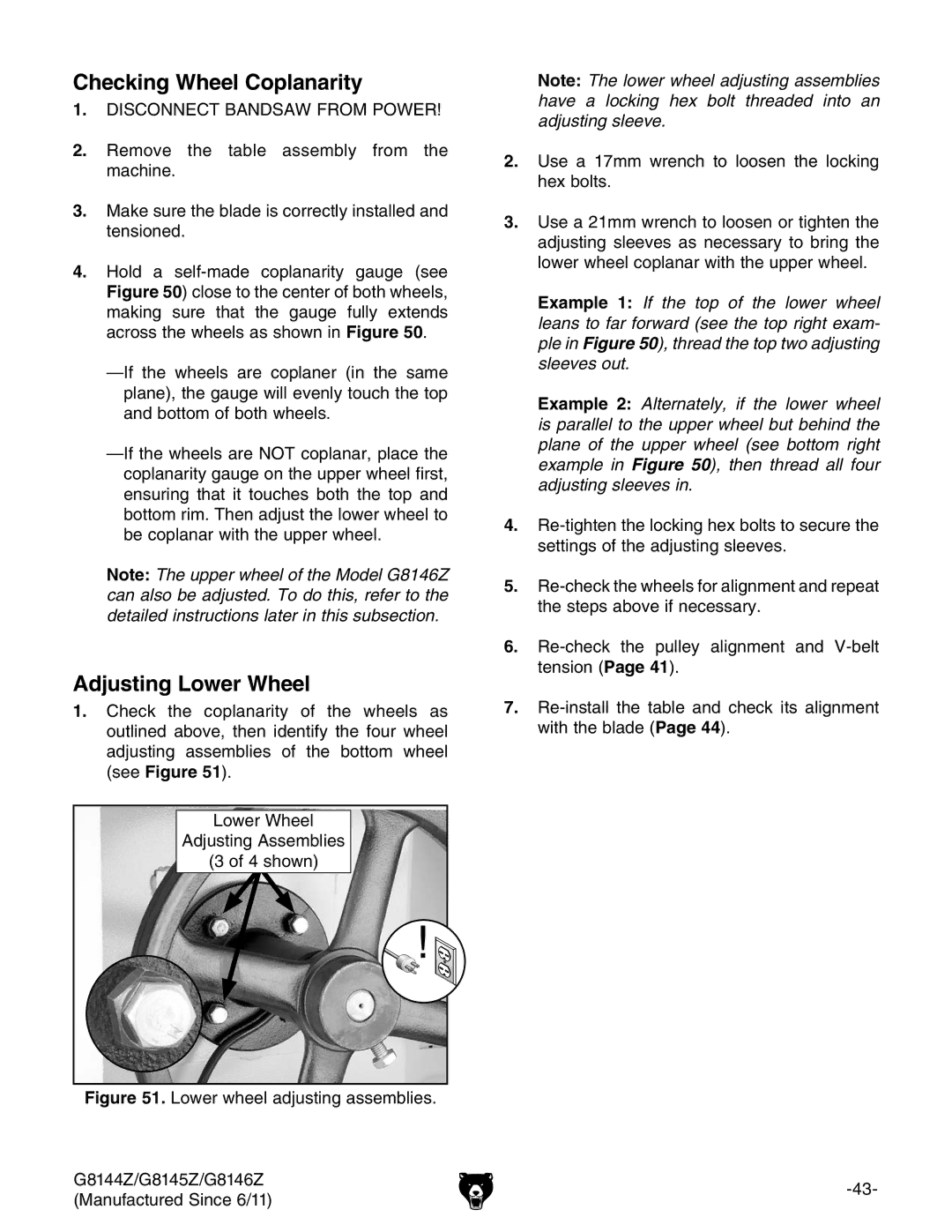

1.Check the coplanarity of the wheels as outlined above, then identify the four wheel adjusting assemblies of the bottom wheel (see Figure 51).

Lower Wheel |

Adjusting Assemblies |

(3 of 4 shown) |

Figure 51. Lower wheel adjusting assemblies.

Note: The lower wheel adjusting assemblies have a locking hex bolt threaded into an adjusting sleeve.

2.Use a 17mm wrench to loosen the locking hex bolts.

3.Use a 21mm wrench to loosen or tighten the adjusting sleeves as necessary to bring the lower wheel coplanar with the upper wheel.

Example 1: If the top of the lower wheel leans to far forward (see the top right exam- ple in Figure 50), thread the top two adjusting sleeves out.

Example 2: Alternately, if the lower wheel is parallel to the upper wheel but behind the plane of the upper wheel (see bottom right example in Figure 50), then thread all four adjusting sleeves in.

4.

5.

6.

7.

G8144Z/G8145Z/G8146Z | ||

(Manufactured Since 6/11) | ||

|