Basic Tenon Cutting

Your new tenoning jig is designed to make tenon cheek cuts only, and generally, cheek cuts are made before the shoulder cuts. This procedure will guide you through three parts; A, B, and C to show you how to cut your first basic tenon.

A. Preparing the tenoning jig and workpiece:

Note: The shoulder cuts and angle cuts are made on the table saw with the miter gauge.

1.Select your mortise and tenon joints, and draw the cutting lines as shown in Figure 16. Make sure to account for the thickness of the saw blade.

Figure 16. Tenon layout.

H7583 Tenoning Jig

WEAR your safety glass- es when you perform any assembly, operation, and maintenance. Failure to comply may result in serious personal injury.

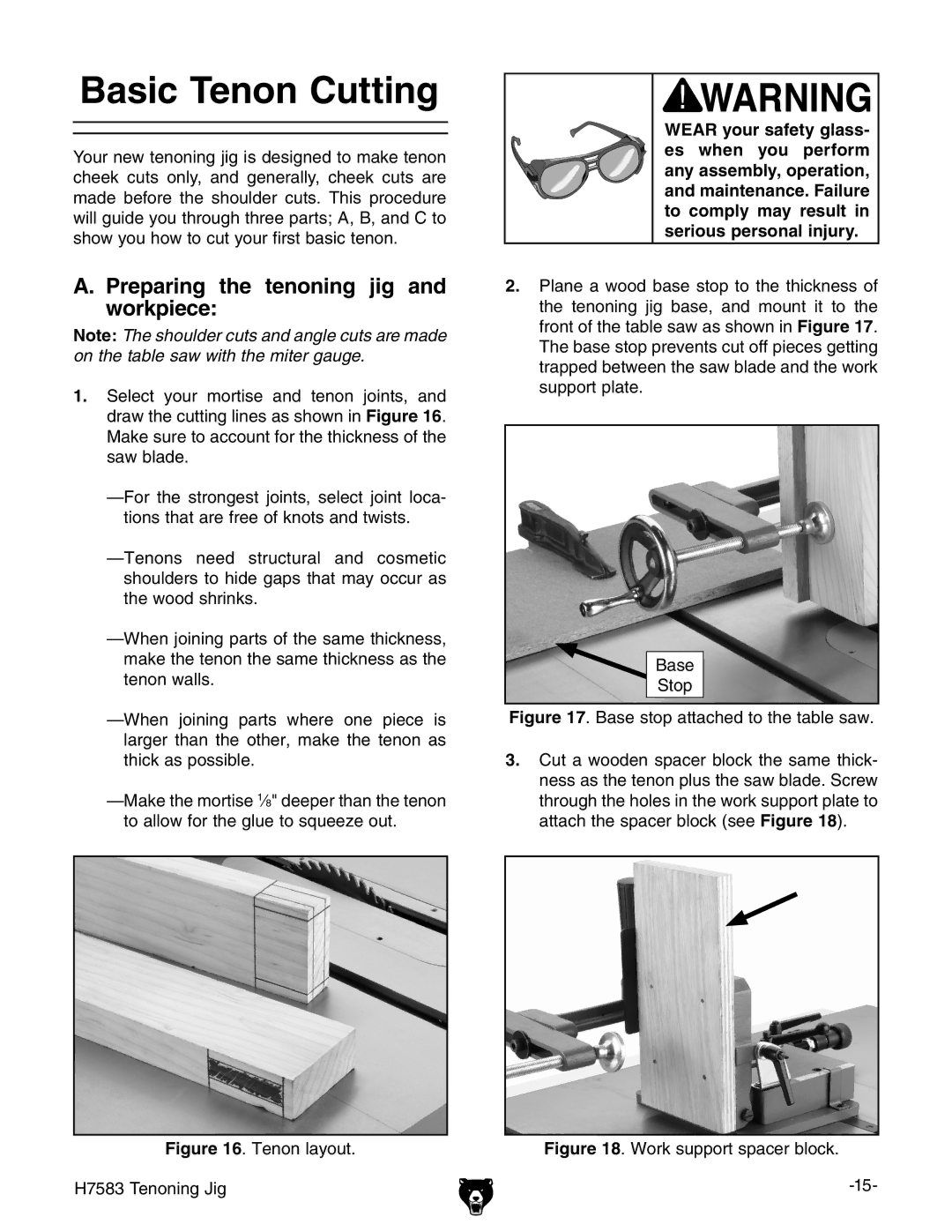

2.Plane a wood base stop to the thickness of the tenoning jig base, and mount it to the front of the table saw as shown in Figure 17. The base stop prevents cut off pieces getting trapped between the saw blade and the work support plate.

Base

Stop