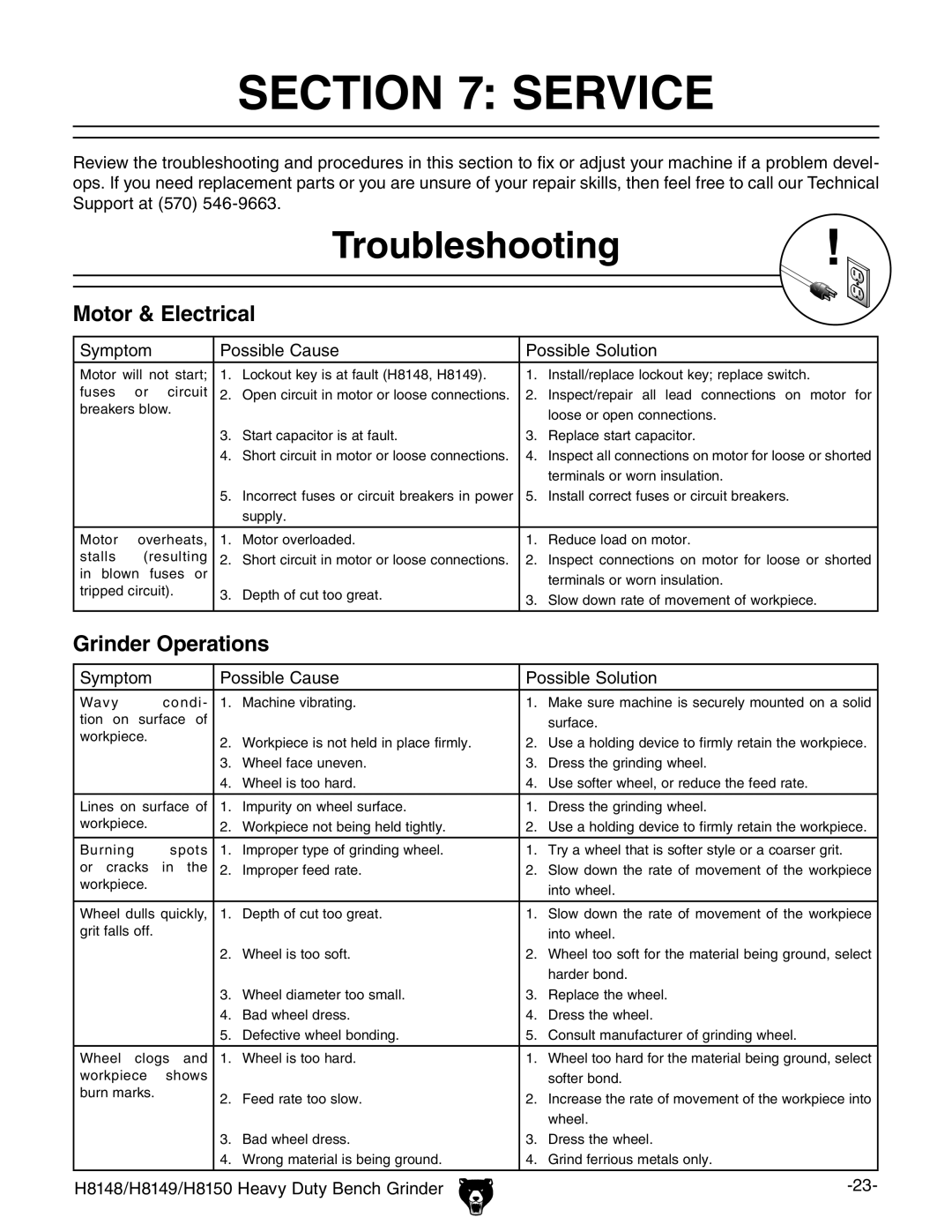

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Motor & Electrical

Symptom | Possible Cause | Possible Solution | |||||

|

|

|

|

| |||

Motor will not start; | 1. | Lockout key is at fault (H8148, H8149). | 1. | Install/replace lockout key; replace switch. | |||

fuses | or | circuit | 2. | Open circuit in motor or loose connections. | 2. | Inspect/repair all lead connections on motor for | |

breakers blow. |

|

|

| loose or open connections. | |||

|

|

|

|

|

| ||

|

|

| 3. | Start capacitor is at fault. | 3. | Replace start capacitor. | |

|

|

| 4. | Short circuit in motor or loose connections. | 4. | Inspect all connections on motor for loose or shorted | |

|

|

|

|

|

| terminals or worn insulation. | |

|

|

| 5. | Incorrect fuses or circuit breakers in power | 5. | Install correct fuses or circuit breakers. | |

|

|

|

| supply. |

|

| |

|

|

|

|

|

| ||

Motor | overheats, | 1. | Motor overloaded. | 1. | Reduce load on motor. | ||

stalls | (resulting | 2. | Short circuit in motor or loose connections. | 2. | Inspect connections on motor for loose or shorted | ||

in blown | fuses or |

|

|

| terminals or worn insulation. | ||

tripped circuit). | 3. | Depth of cut too great. |

| ||||

3. | Slow down rate of movement of workpiece. | ||||||

|

|

| |||||

|

|

|

|

| |||

|

|

|

|

|

|

| |

Grinder Operations

Symptom |

|

| Possible Cause | Possible Solution | |||

|

|

|

|

|

|

| |

Wavy |

| condi- | 1. | Machine vibrating. | 1. | Make sure machine is securely mounted on a solid | |

tion on | surface of |

|

|

| surface. | ||

workpiece. |

|

| 2. | Workpiece is not held in place firmly. | 2. | Use a holding device to firmly retain the workpiece. | |

|

|

|

| ||||

|

|

|

| 3. | Wheel face uneven. | 3. | Dress the grinding wheel. |

|

|

|

| 4. | Wheel is too hard. | 4. | Use softer wheel, or reduce the feed rate. |

|

|

|

|

| |||

Lines on surface of | 1. | Impurity on wheel surface. | 1. | Dress the grinding wheel. | |||

workpiece. |

|

| 2. | Workpiece not being held tightly. | 2. | Use a holding device to firmly retain the workpiece. | |

|

|

|

|

|

|

| |

Burning |

| spots | 1. | Improper type of grinding wheel. | 1. | Try a wheel that is softer style or a coarser grit. | |

or cracks | in | the | 2. | Improper feed rate. | 2. | Slow down the rate of movement of the workpiece | |

workpiece. |

|

|

|

|

| into wheel. | |

|

|

|

|

|

|

| |

|

|

|

|

| |||

Wheel dulls quickly, | 1. | Depth of cut too great. | 1. | Slow down the rate of movement of the workpiece | |||

grit falls off. |

|

|

|

|

| into wheel. | |

|

|

|

| 2. | Wheel is too soft. | 2. | Wheel too soft for the material being ground, select |

|

|

|

|

|

|

| harder bond. |

|

|

|

| 3. | Wheel diameter too small. | 3. | Replace the wheel. |

|

|

|

| 4. | Bad wheel dress. | 4. | Dress the wheel. |

|

|

|

| 5. | Defective wheel bonding. | 5. | Consult manufacturer of grinding wheel. |

|

|

|

|

|

|

| |

Wheel | clogs | and | 1. | Wheel is too hard. | 1. | Wheel too hard for the material being ground, select | |

workpiece | shows |

|

|

| softer bond. | ||

burn marks. |

|

| 2. | Feed rate too slow. | 2. | Increase the rate of movement of the workpiece into | |

|

|

|

| ||||

|

|

|

|

|

|

| wheel. |

|

|

|

| 3. | Bad wheel dress. | 3. | Dress the wheel. |

|

|

|

| 4. | Wrong material is being ground. | 4. | Grind ferrious metals only. |

|

|

|

| ||||

H8148/H8149/H8150 Heavy Duty Bench Grinder |

| ||||||