Hot sparks from the blade welding opera- tion could be thrown in all directions and cause burns or fire.

When using the blade welder, always keep the spark deflector over the clamps and protect yourself from the flying sparks. Have fire extinguishing equipment readily available.

DO NOT weld near flammables.

NOTICE

For good

Before welding a blade back together to per- form an internal cut, insulate the entire blade from the metal surfaces of the bandsaw to ensure a good flow of current through the blade.

12.Press and

Note: A limit switch senses the electrical resistance between the blade ends. If there is an adequate amount of welded material, the limit switch will not allow the weld button to activate the operation again.

13.Allow the blade to cool.

14.Rotate the clamp lever switch to zero to release the clamp pressure.

15.Remove the blade.

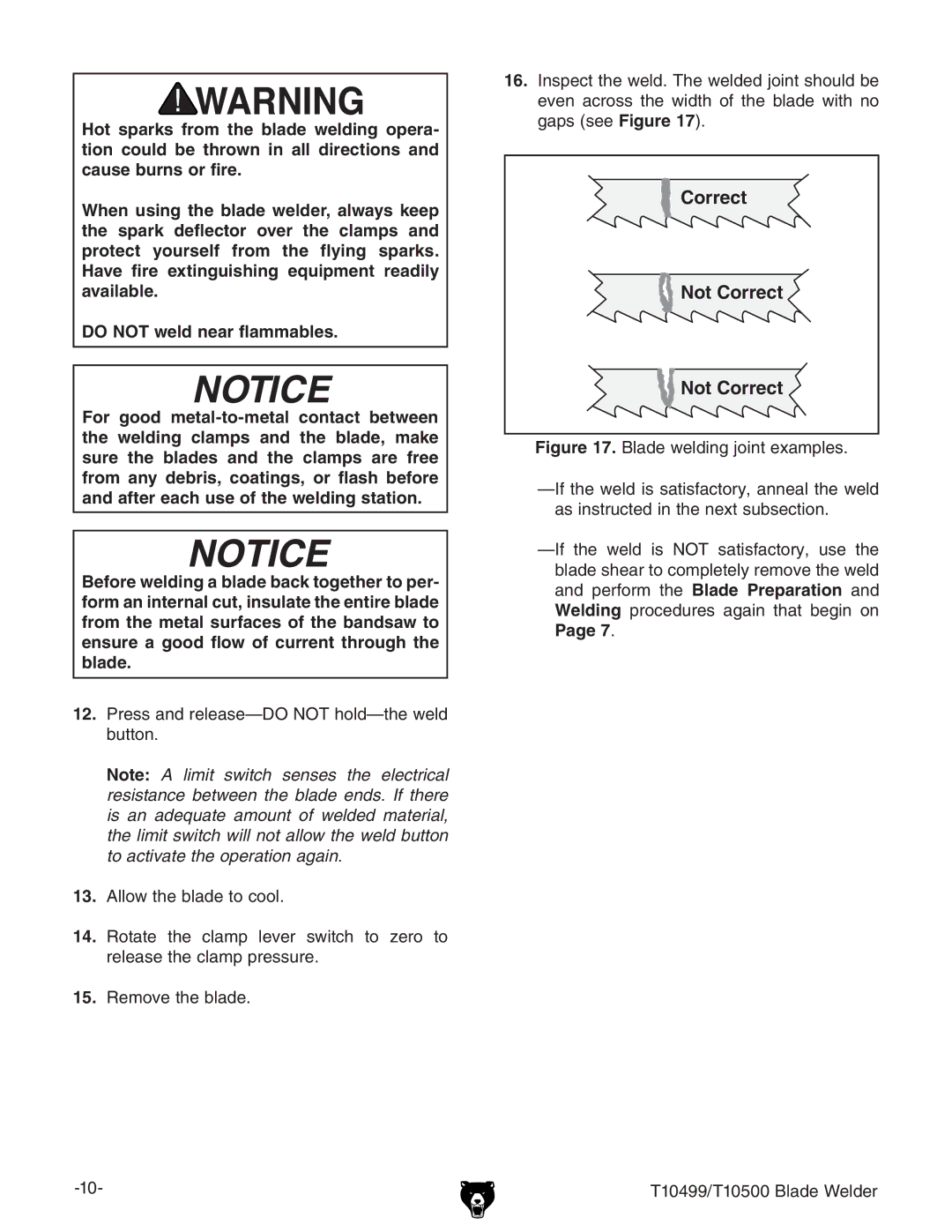

16.Inspect the weld. The welded joint should be even across the width of the blade with no gaps (see Figure 17).

Correct

Correct

Not Correct

Not Correct

![]() Not Correct

Not Correct ![]()