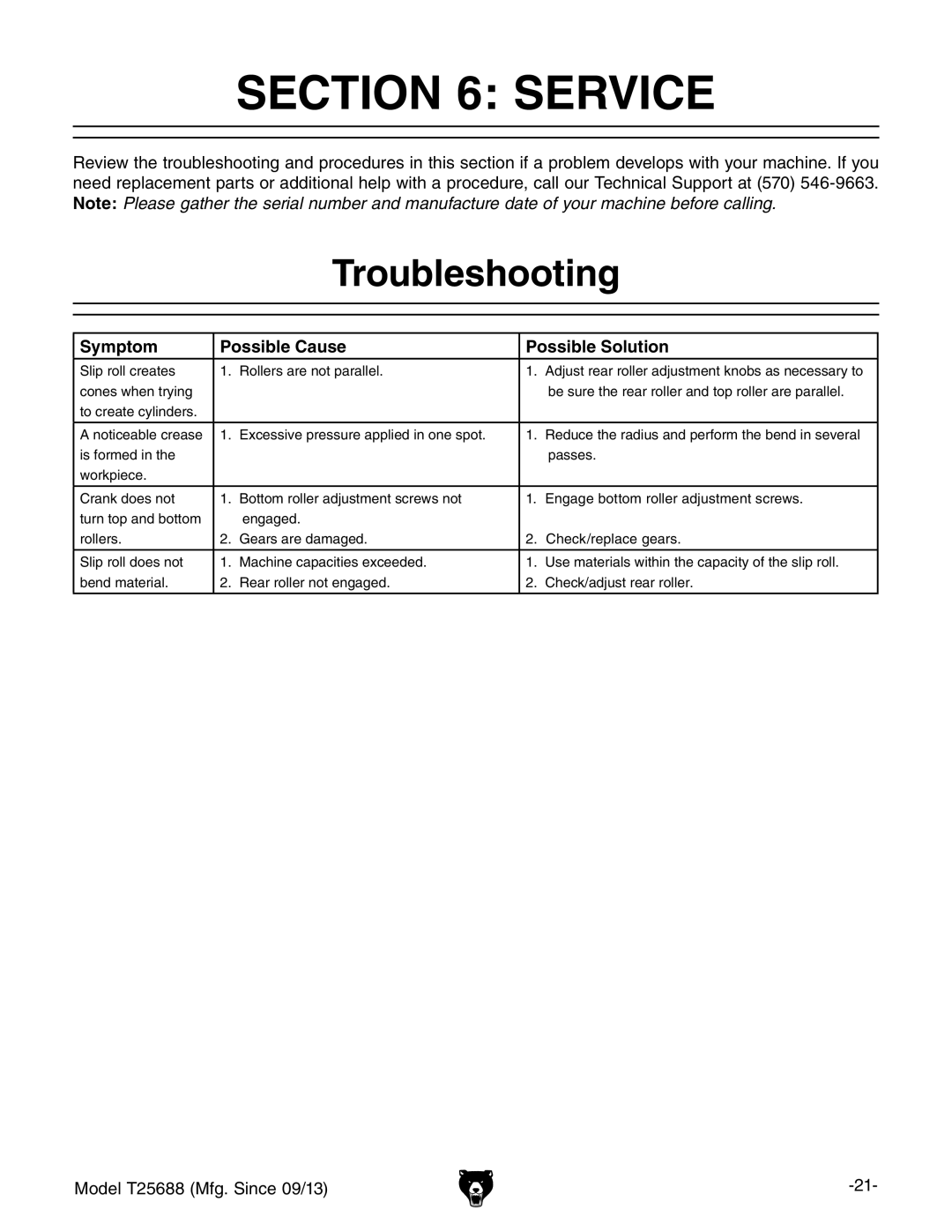

SECTION 6: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

Slip roll creates | 1. | Rollers are not parallel. | 1. | Adjust rear roller adjustment knobs as necessary to |

cones when trying |

|

|

| be sure the rear roller and top roller are parallel. |

to create cylinders. |

|

|

|

|

|

|

|

|

|

A noticeable crease | 1. | Excessive pressure applied in one spot. | 1. | Reduce the radius and perform the bend in several |

is formed in the |

|

|

| passes. |

workpiece. |

|

|

|

|

|

|

|

|

|

Crank does not | 1. | Bottom roller adjustment screws not | 1. | Engage bottom roller adjustment screws. |

turn top and bottom |

| engaged. |

|

|

rollers. | 2. | Gears are damaged. | 2. | Check/replace gears. |

|

|

|

|

|

Slip roll does not | 1. | Machine capacities exceeded. | 1. | Use materials within the capacity of the slip roll. |

bend material. | 2. | Rear roller not engaged. | 2. | Check/adjust rear roller. |

|

|

|

|

|

Model T25688 (Mfg. Since 09/13) |