SECTION 5 : MAINTENANCE

Schedule

For optimum performance from the machine, fol- low this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Loose mounting bolts.

•Any other unsafe condition.

Weekly Maintenance:

•Clean machine.

•Lubricate gears.

•Lubricate roller bushings.

Cleaning

Cleaning the Model T25688 is relatively easy. Periodically wipe down the rollers to remove dust and

Treat all unpainted metal surfaces with quality metal protectants like SLipit®, or Boeshield®

Lubrication

Roller Gears

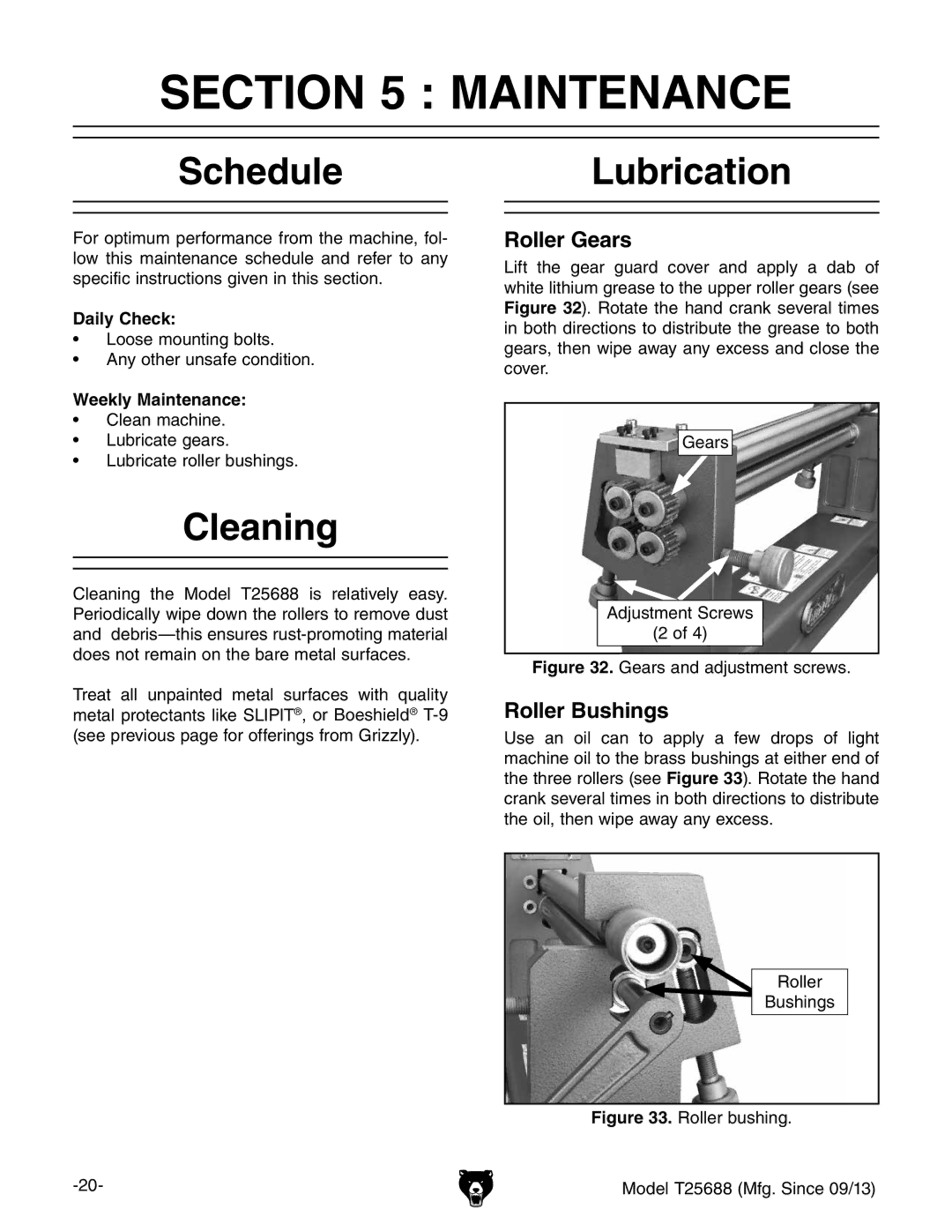

Lift the gear guard cover and apply a dab of white lithium grease to the upper roller gears (see Figure 32). Rotate the hand crank several times in both directions to distribute the grease to both gears, then wipe away any excess and close the cover.

Gears

Adjustment Screws

(2 of 4)

Figure 32. Gears and adjustment screws.

Roller Bushings

Use an oil can to apply a few drops of light machine oil to the brass bushings at either end of the three rollers (see Figure 33). Rotate the hand crank several times in both directions to distribute the oil, then wipe away any excess.

Roller

![]() Bushings

Bushings