Installation Procedure

|

| Insert | |

|

| Washer fixing pad | |

Level | Polythene pipe | (prepared in feild) | |

[ secure the washer firmly] | |||

| |||

|

|

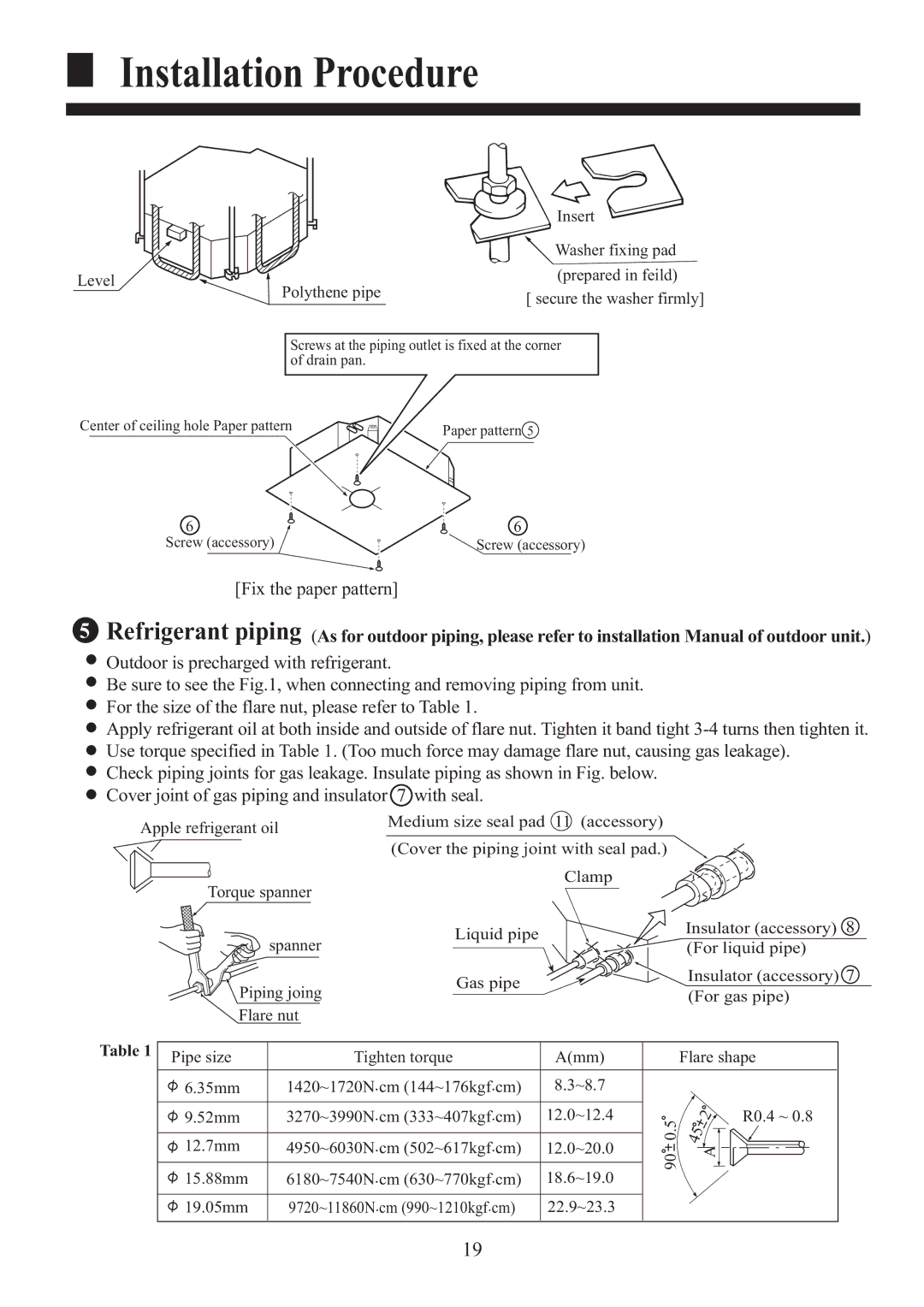

Screws at the piping outlet is fixed at the corner of drain pan.

Center of ceiling hole Paper pattern | Paper pattern 5 |

|

6 | 6 |

Screw (accessory) | Screw (accessory) |

[Fix the paper pattern]

5Refrigerant piping (As for outdoor piping, please refer to installation Manual of outdoor unit.)

Outdoor is precharged with refrigerant.

Be sure to see the Fig.1, when connecting and removing piping from unit. For the size of the flare nut, please refer to Table 1.

Apply refrigerant oil at both inside and outside of flare nut. Tighten it band tight

Check piping joints for gas leakage. Insulate piping as shown in Fig. below. Cover joint of gas piping and insulator 7 with seal.

Apple refrigerant oil

Torque spanner

![]() spanner

spanner

Piping joing

Flare nut

Medium size seal pad 11 (accessory) (Cover the piping joint with seal pad.)

Clamp

Liquid pipe

Gas pipe

Insulator (accessory) 8

(For liquid pipe)

Insulator (accessory) 7

(For gas pipe)

Table 1 |

| Pipe size |

| Tighten torque |

| A(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |||

|

| 6.35mm |

| 1420~1720N.cm (144~176kgf.cm) |

| 8.3~8.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9.52mm |

| 3270~3990N.cm (333~407kgf.cm) |

| 12.0~12.4 | 0.5 | |||||

|

|

|

|

|

|

| ||||||

|

| 12.7mm |

| 4950~6030N.cm (502~617kgf.cm) |

| 12.0~20.0 | ||||||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

| 90 | ||||||||

|

|

|

|

|

|

| ||||||

|

| 15.88mm |

| 6180~7540N.cm (630~770kgf.cm) |

| 18.6~19.0 | ||||||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 19.05mm |

| 9720~11860N.cm (990~1210kgf.cm) |

| 22.9~23.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flare shape

45 | 2 | R0.4 ~ 0.8 |

| ||

A |

| |

|

|

19