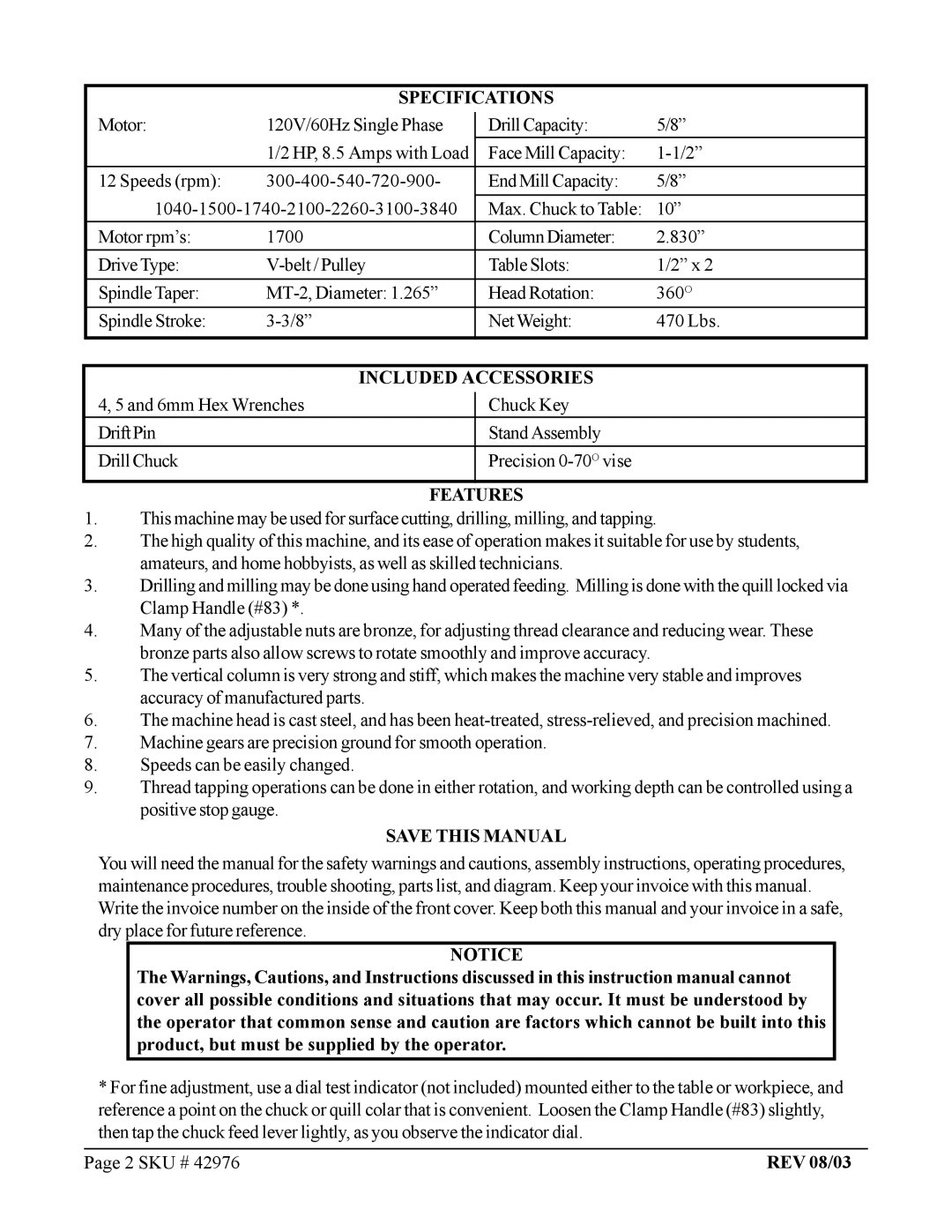

| SPECIFICATIONS |

| ||

Motor: | 120V/60Hz Single Phase |

| Drill Capacity: | 5/8” |

| ||||

|

|

|

|

|

| 1/2 HP, 8.5 Amps with Load |

| Face Mill Capacity: | |

|

|

|

|

|

12 Speeds (rpm): |

| End Mill Capacity: | 5/8” | |

|

|

|

| |

| Max. Chuck to Table: | 10” | ||

|

|

|

|

|

Motor rpm’s: | 1700 |

| Column Diameter: | 2.830” |

|

|

|

|

|

Drive Type: |

| Table Slots: | 1/2” x 2 | |

|

|

|

|

|

Spindle Taper: |

| Head Rotation: | 360O | |

|

|

|

|

|

Spindle Stroke: |

| Net Weight: | 470 Lbs. | |

|

|

|

|

|

| INCLUDED ACCESSORIES | |

4, 5 and 6mm Hex Wrenches |

| Chuck Key |

| ||

|

|

|

DriftPin |

| Stand Assembly |

|

|

|

Drill Chuck |

| Precision |

|

|

|

| FEATURES | |

1.This machine may be used for surface cutting, drilling, milling, and tapping.

2.The high quality of this machine, and its ease of operation makes it suitable for use by students, amateurs, and home hobbyists, as well as skilled technicians.

3.Drilling and milling may be done using hand operated feeding. Milling is done with the quill locked via Clamp Handle (#83) *.

4.Many of the adjustable nuts are bronze, for adjusting thread clearance and reducing wear. These bronze parts also allow screws to rotate smoothly and improve accuracy.

5.The vertical column is very strong and stiff, which makes the machine very stable and improves accuracy of manufactured parts.

6.The machine head is cast steel, and has been

7.Machine gears are precision ground for smooth operation.

8.Speeds can be easily changed.

9.Thread tapping operations can be done in either rotation, and working depth can be controlled using a positive stop gauge.

SAVE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice with this manual. Write the invoice number on the inside of the front cover. Keep both this manual and your invoice in a safe, dry place for future reference.

NOTICE

The Warnings, Cautions, and Instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

*For fine adjustment, use a dial test indicator (not included) mounted either to the table or workpiece, and reference a point on the chuck or quill colar that is convenient. Loosen the Clamp Handle (#83) slightly, then tap the chuck feed lever lightly, as you observe the indicator dial.

Page 2 SKU # 42976 | REV 08/03 |