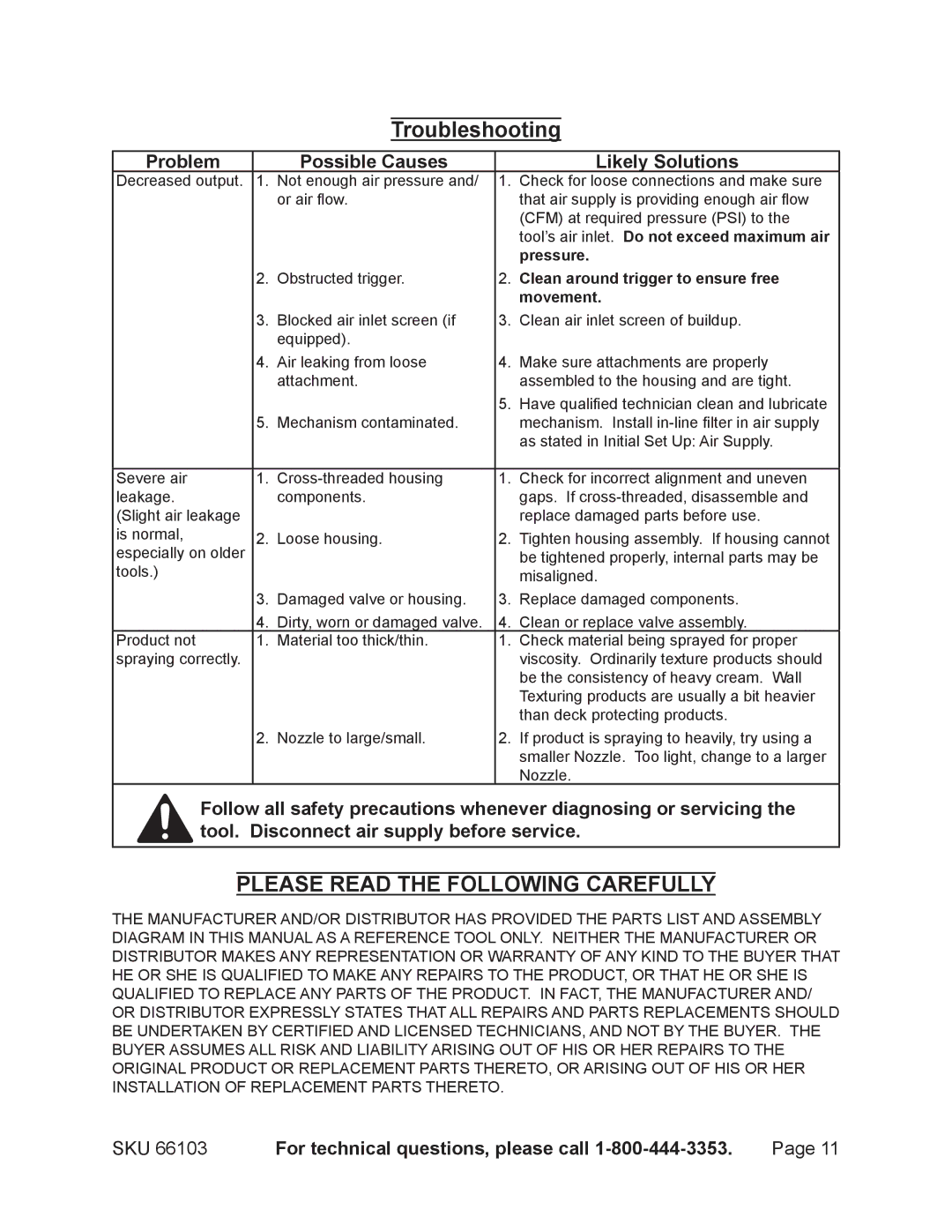

Troubleshooting

Problem | Possible Causes |

| Likely Solutions |

Decreased output. 1. Not enough air pressure and/ | 1. | Check for loose connections and make sure | |

| or air flow. |

| that air supply is providing enough air flow |

|

|

| (CFM) at required pressure (PSI) to the |

|

|

| tool’s air inlet. Do not exceed maximum air |

|

|

| pressure. |

2. | Obstructed trigger. | 2. | Clean around trigger to ensure free |

|

|

| movement. |

3. | Blocked air inlet screen (if | 3. | Clean air inlet screen of buildup. |

| equipped). |

|

|

4. | Air leaking from loose | 4. | Make sure attachments are properly |

| attachment. |

| assembled to the housing and are tight. |

|

| 5. | Have qualified technician clean and lubricate |

5.Mechanism contaminated. mechanism. Install

Severe air | 1. | 1. | Check for incorrect alignment and uneven | |

leakage. |

| components. |

| gaps. If |

(Slight air leakage |

|

|

| replace damaged parts before use. |

is normal, | 2. | Loose housing. | 2. | Tighten housing assembly. If housing cannot |

especially on older |

|

|

| be tightened properly, internal parts may be |

tools.) |

|

|

| misaligned. |

| 3. | Damaged valve or housing. | 3. | Replace damaged components. |

| 4. | Dirty, worn or damaged valve. 4. Clean or replace valve assembly. | ||

Product not | 1. | Material too thick/thin. | 1. | Check material being sprayed for proper |

spraying correctly. |

|

|

| viscosity. Ordinarily texture products should |

|

|

|

| be the consistency of heavy cream. Wall |

|

|

|

| Texturing products are usually a bit heavier |

|

|

|

| than deck protecting products. |

| 2. | Nozzle to large/small. | 2. | If product is spraying to heavily, try using a |

|

|

|

| smaller Nozzle. Too light, change to a larger |

|

|

|

| Nozzle. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

The manufacturer and/or distributor has provided the parts list and assembly diagram in this manual as a reference tool only. Neither the manufacturer or distributor makes any representation or warranty of any kind to the buyer that he or she is qualified to make any repairs to the product, or that he or she is qualified to replace any parts of the product. In fact, the manufacturer and/ or distributor expressly states that all repairs and parts replacements should be undertaken by certified and licensed technicians, and not by the buyer. The buyer assumes all risk and liability arising out of his or her repairs to the original product or replacement parts thereto, or arising out of his or her installation of replacement parts thereto.

SKU 66103 | For technical questions, please call | Page 11 |