Operation

After reading these instructions,

consider the following points before starting the pump:

1.Verify that the pump rests on the floor of the shaft, if it is not suspended by the handle.

2.Verify that the delivery pipe is properly connected.

3.Verify that the electrical connection is 120 V~, 60 Hz, and

4.Verify that the electrical socket is in good condition.

5.Verify that water and moisture cannot get near the power supply socket.

6.Verify that the pump is installed so as to prevent running dry.

7.Verify that the power cords do not have excess slack in the Sump Basin to prevent it from interfering with the Float Switch. Secure them to the Discharge Pipe if needed.

8.Dry the floor and your hands,

then plug the Float Switch Cord into

a grounded,

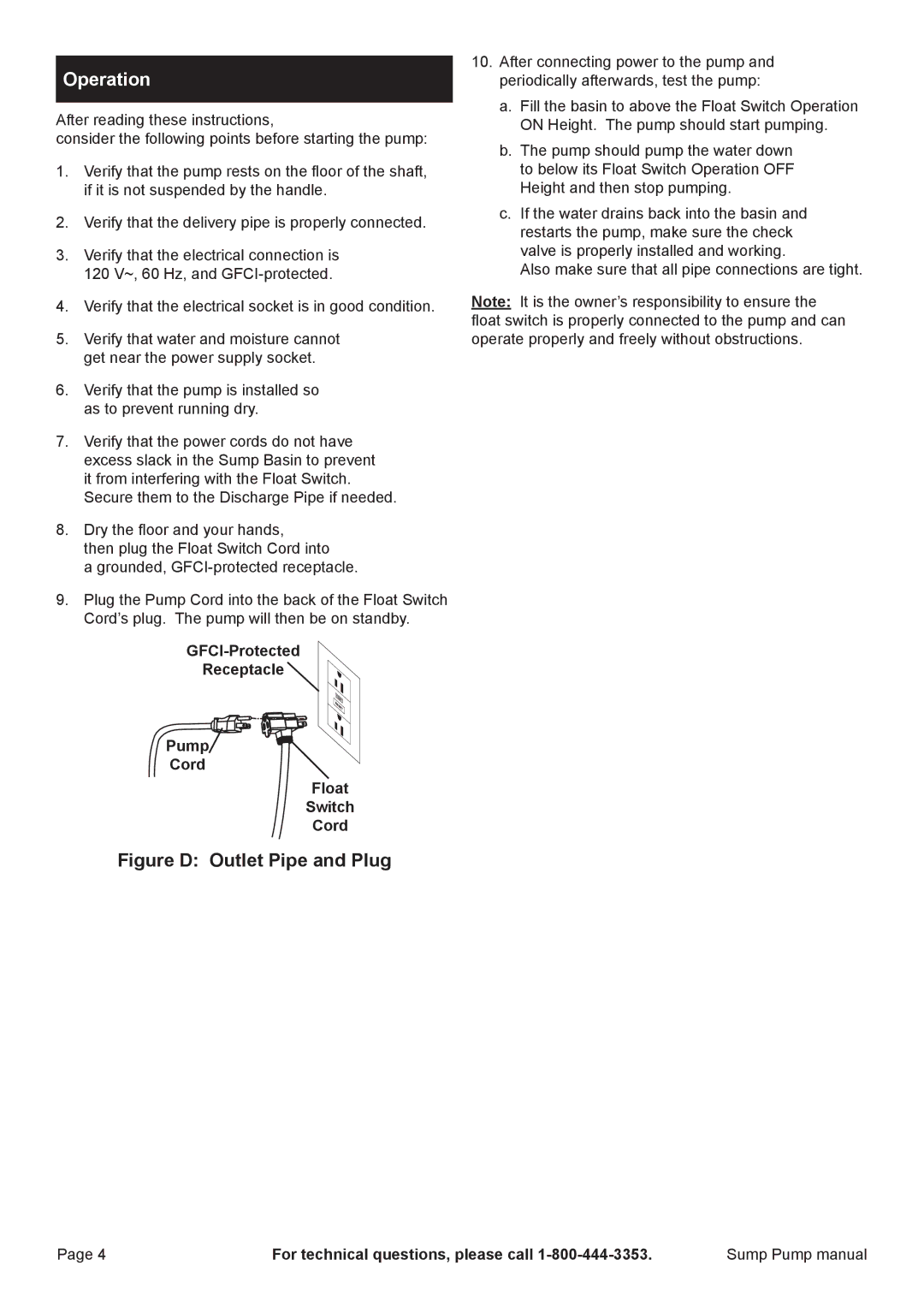

9.Plug the Pump Cord into the back of the Float Switch Cord’s plug. The pump will then be on standby.

GFCI-Protected

Receptacle

Pump

Cord

Float

Switch

Cord

Figure D: Outlet Pipe and Plug

10.After connecting power to the pump and periodically afterwards, test the pump:

a.Fill the basin to above the Float Switch Operation ON Height. The pump should start pumping.

b.The pump should pump the water down to below its Float Switch Operation OFF Height and then stop pumping.

c.If the water drains back into the basin and restarts the pump, make sure the check valve is properly installed and working.

Also make sure that all pipe connections are tight.

Note: It is the owner’s responsibility to ensure the float switch is properly connected to the pump and can operate properly and freely without obstructions.

Page 4 | For technical questions, please call | Sump Pump manual |