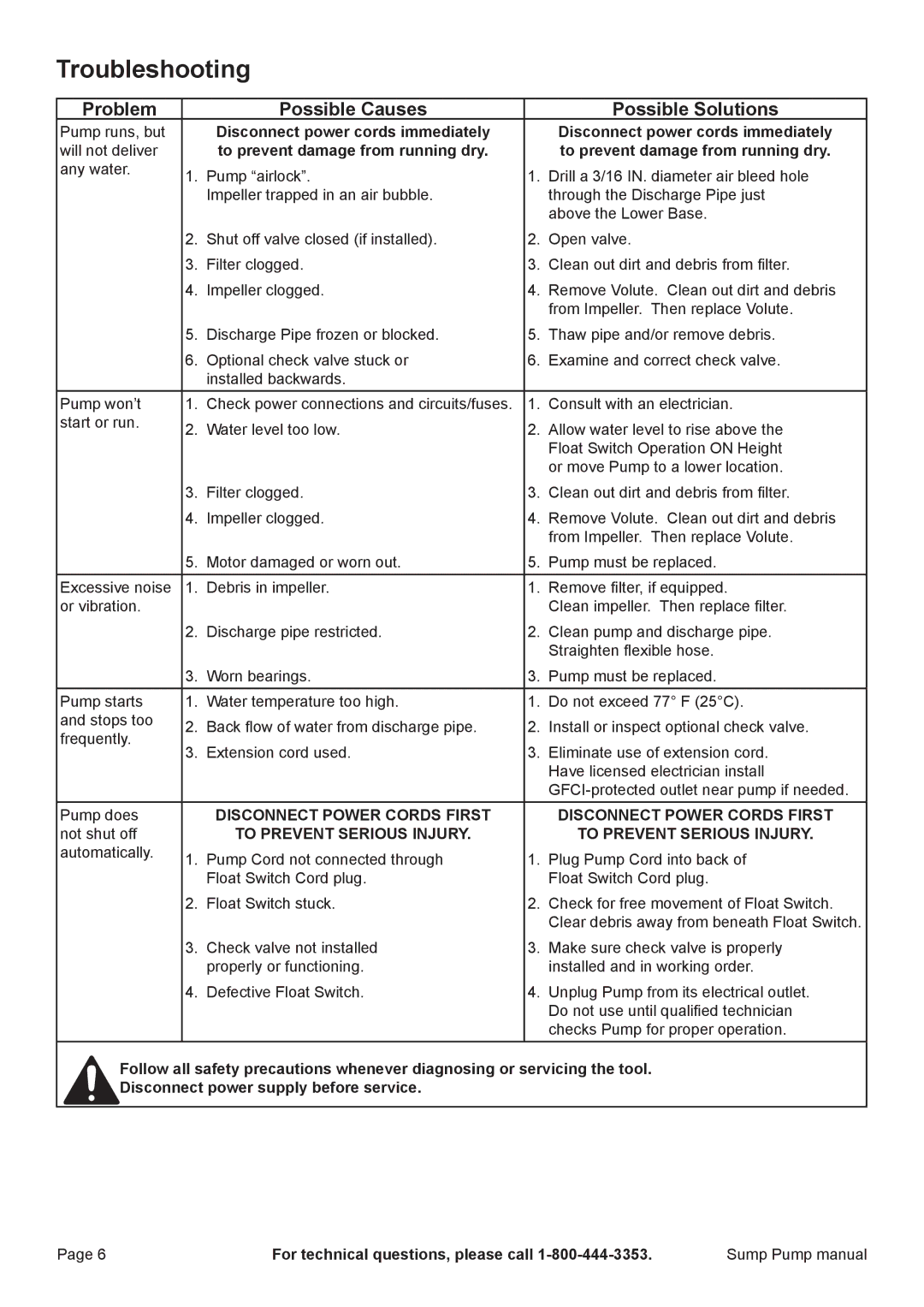

Troubleshooting

Problem |

| Possible Causes |

| Possible Solutions | |

Pump runs, but |

| Disconnect power cords immediately |

| Disconnect power cords immediately | |

will not deliver |

| to prevent damage from running dry. |

| to prevent damage from running dry. | |

any water. | 1. | Pump “airlock”. | 1. | Drill a 3/16 IN. diameter air bleed hole | |

| |||||

|

| Impeller trapped in an air bubble. |

| through the Discharge Pipe just | |

|

|

|

| above the Lower Base. | |

| 2. | Shut off valve closed (if installed). | 2. | Open valve. | |

| 3. | Filter clogged. | 3. | Clean out dirt and debris from filter. | |

| 4. | Impeller clogged. | 4. | Remove Volute. Clean out dirt and debris | |

|

|

|

| from Impeller. Then replace Volute. | |

| 5. | Discharge Pipe frozen or blocked. | 5. | Thaw pipe and/or remove debris. | |

| 6. | Optional check valve stuck or | 6. | Examine and correct check valve. | |

|

| installed backwards. |

|

| |

Pump won’t | 1. Check power connections and circuits/fuses. | 1. | Consult with an electrician. | ||

start or run. | 2. | Water level too low. | 2. | Allow water level to rise above the | |

| |||||

|

|

|

| Float Switch Operation ON Height | |

|

|

|

| or move Pump to a lower location. | |

| 3. | Filter clogged. | 3. | Clean out dirt and debris from filter. | |

| 4. | Impeller clogged. | 4. | Remove Volute. Clean out dirt and debris | |

|

|

|

| from Impeller. Then replace Volute. | |

| 5. | Motor damaged or worn out. | 5. | Pump must be replaced. | |

Excessive noise | 1. | Debris in impeller. | 1. | Remove filter, if equipped. | |

or vibration. |

|

|

| Clean impeller. Then replace filter. | |

| 2. | Discharge pipe restricted. | 2. | Clean pump and discharge pipe. | |

|

|

|

| Straighten flexible hose. | |

| 3. | Worn bearings. | 3. | Pump must be replaced. | |

Pump starts | 1. Water temperature too high. | 1. | Do not exceed 77° F (25°C). | ||

and stops too | 2. | Back flow of water from discharge pipe. | 2. | Install or inspect optional check valve. | |

frequently. | |||||

3. | Extension cord used. | 3. | Eliminate use of extension cord. | ||

| |||||

|

|

|

| Have licensed electrician install | |

|

|

|

| GFCI‑protected outlet near pump if needed. | |

Pump does |

| DISCONNECT POWER CORDS FIRST |

| DISCONNECT POWER CORDS FIRST | |

not shut off |

| TO PREVENT SERIOUS INJURY. |

| TO PREVENT SERIOUS INJURY. | |

automatically. | 1. | Pump Cord not connected through | 1. | Plug Pump Cord into back of | |

| |||||

|

| Float Switch Cord plug. |

| Float Switch Cord plug. | |

| 2. | Float Switch stuck. | 2. | Check for free movement of Float Switch. | |

|

|

|

| Clear debris away from beneath Float Switch. | |

| 3. | Check valve not installed | 3. | Make sure check valve is properly | |

|

| properly or functioning. |

| installed and in working order. | |

| 4. | Defective Float Switch. | 4. | Unplug Pump from its electrical outlet. | |

|

|

|

| Do not use until qualified technician | |

|

|

|

| checks Pump for proper operation. | |

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect power supply before service.

Page 6 | For technical questions, please call | Sump Pump manual |