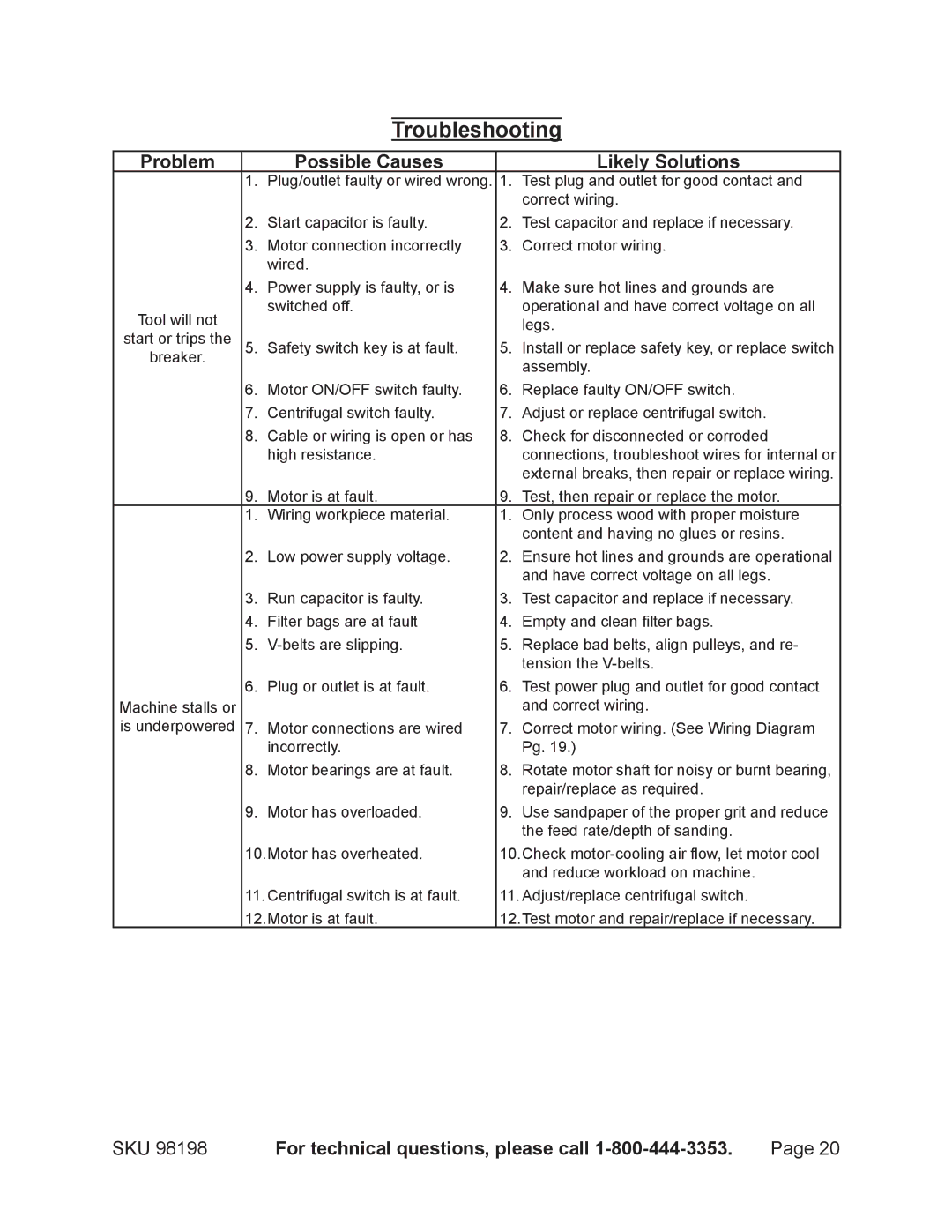

Troubleshooting

Problem | Possible Causes | Likely Solutions |

1.Plug/outlet faulty or wired wrong. 1. Test plug and outlet for good contact and correct wiring.

| 2. | Start capacitor is faulty. | 2. | Test capacitor and replace if necessary. |

| 3. | Motor connection incorrectly | 3. | Correct motor wiring. |

|

| wired. |

|

|

| 4. | Power supply is faulty, or is | 4. | Make sure hot lines and grounds are |

Tool will not |

| switched off. |

| operational and have correct voltage on all |

|

|

| legs. | |

start or trips the | 5. | Safety switch key is at fault. | 5. | Install or replace safety key, or replace switch |

breaker. |

|

|

| assembly. |

|

|

|

| |

| 6. | Motor ON/OFF switch faulty. | 6. | Replace faulty ON/OFF switch. |

| 7. | Centrifugal switch faulty. | 7. | Adjust or replace centrifugal switch. |

| 8. | Cable or wiring is open or has | 8. | Check for disconnected or corroded |

|

| high resistance. |

| connections, troubleshoot wires for internal or |

|

|

|

| external breaks, then repair or replace wiring. |

| 9. | Motor is at fault. | 9. | Test, then repair or replace the motor. |

| 1. | Wiring workpiece material. | 1. | Only process wood with proper moisture |

|

|

|

| content and having no glues or resins. |

2.Low power supply voltage. 2. Ensure hot lines and grounds are operational and have correct voltage on all legs.

3. | Run capacitor is faulty. | 3. | Test capacitor and replace if necessary. |

4. | Filter bags are at fault | 4. | Empty and clean filter bags. |

5. | 5. | Replace bad belts, align pulleys, and re- | |

|

|

| tension the |

6. | Plug or outlet is at fault. | 6. | Test power plug and outlet for good contact |

Machine stalls or |

|

| and correct wiring. |

is underpowered 7. | Motor connections are wired | 7. | Correct motor wiring. (See Wiring Diagram |

| incorrectly. |

| Pg. 19.) |

8. | Motor bearings are at fault. | 8. | Rotate motor shaft for noisy or burnt bearing, |

|

|

| repair/replace as required. |

9. | Motor has overloaded. | 9. | Use sandpaper of the proper grit and reduce |

|

|

| the feed rate/depth of sanding. |

10.Motor has overheated. | 10.Check | ||

|

|

| and reduce workload on machine. |

11. Centrifugal switch is at fault. | 11. Adjust/replace centrifugal switch. | ||

12.Motor is at fault. | 12.Test motor and repair/replace if necessary. | ||

SKU 98198 | For technical questions, please call | Page 20 |