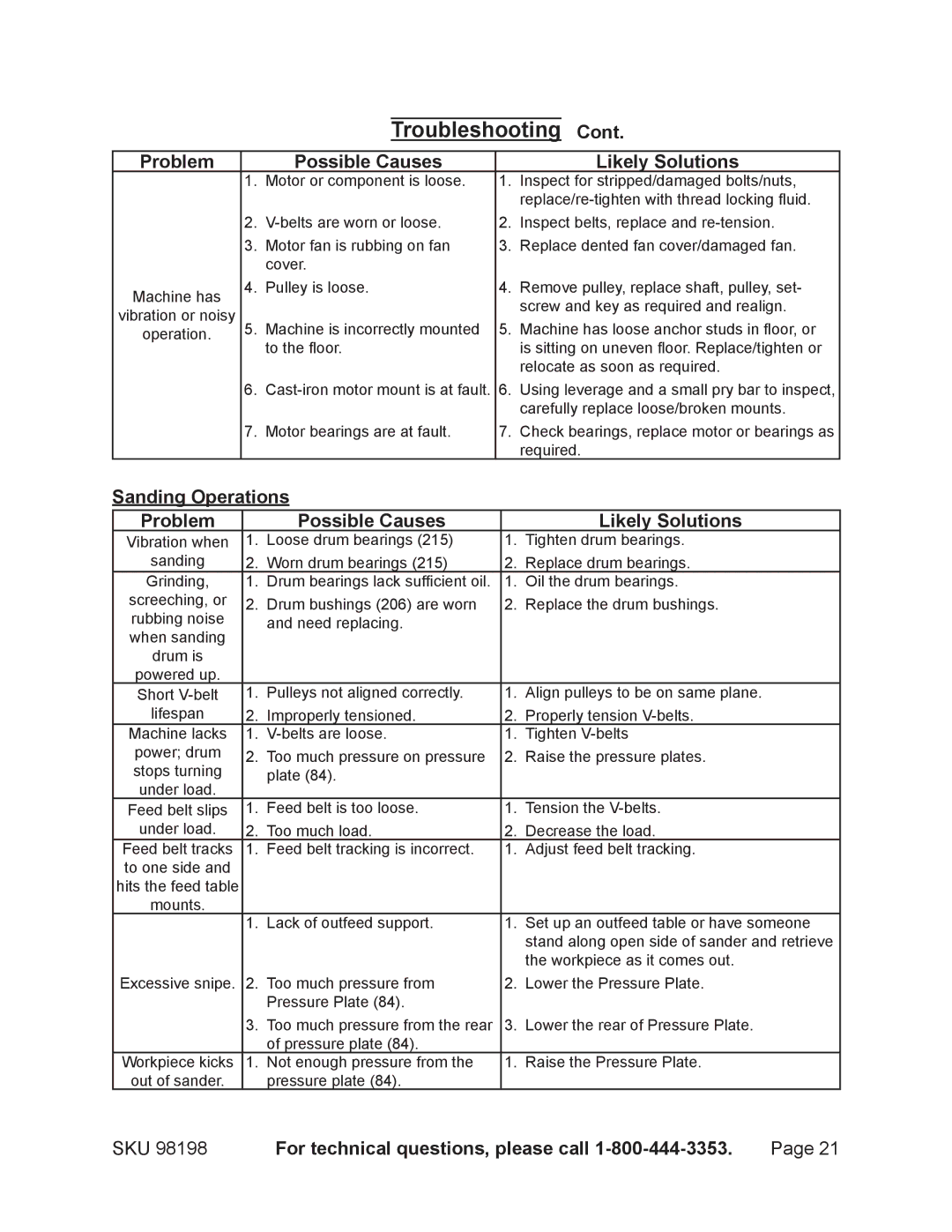

Troubleshooting Cont.

Problem |

| Possible Causes |

| Likely Solutions | |

| 1. | Motor or component is loose. | 1. | Inspect for stripped/damaged bolts/nuts, | |

|

|

|

| ||

| 2. | 2. | Inspect belts, replace and | ||

| 3. | Motor fan is rubbing on fan | 3. | Replace dented fan cover/damaged fan. | |

|

| cover. |

|

| |

Machine has | 4. | Pulley is loose. | 4. | Remove pulley, replace shaft, pulley, set- | |

|

|

| screw and key as required and realign. | ||

vibration or noisy |

|

|

| ||

5. | Machine is incorrectly mounted | 5. | Machine has loose anchor studs in floor, or | ||

operation. | |||||

|

| to the floor. |

| is sitting on uneven floor. Replace/tighten or | |

|

|

|

| relocate as soon as required. |

6.

7. Motor bearings are at fault. | 7. Check bearings, replace motor or bearings as |

| required. |

Sanding Operations |

|

| ||

Problem |

| Possible Causes |

| Likely Solutions |

Vibration when | 1. | Loose drum bearings (215) | 1. | Tighten drum bearings. |

sanding | 2. | Worn drum bearings (215) | 2. | Replace drum bearings. |

Grinding, | 1. | Drum bearings lack sufficient oil. | 1. | Oil the drum bearings. |

screeching, or | 2. | Drum bushings (206) are worn | 2. | Replace the drum bushings. |

rubbing noise |

| and need replacing. |

|

|

when sanding |

|

|

|

|

drum is |

|

|

|

|

powered up. |

|

|

|

|

Short | 1. | Pulleys not aligned correctly. | 1. | Align pulleys to be on same plane. |

lifespan | 2. | Improperly tensioned. | 2. | Properly tension |

Machine lacks | 1. | 1. | Tighten | |

power; drum | 2. | Too much pressure on pressure | 2. | Raise the pressure plates. |

stops turning |

| plate (84). |

|

|

under load. |

|

|

|

|

Feed belt slips | 1. | Feed belt is too loose. | 1. | Tension the |

under load. | 2. | Too much load. | 2. | Decrease the load. |

Feed belt tracks | 1. | Feed belt tracking is incorrect. | 1. | Adjust feed belt tracking. |

to one side and |

|

|

|

|

hits the feed table |

|

|

|

|

mounts. |

|

|

|

|

1.Lack of outfeed support. 1. Set up an outfeed table or have someone stand along open side of sander and retrieve the workpiece as it comes out.

Excessive snipe. | 2. | Too much pressure from | 2. | Lower the Pressure Plate. |

|

| Pressure Plate (84). |

|

|

| 3. | Too much pressure from the rear | 3. | Lower the rear of Pressure Plate. |

|

| of pressure plate (84). |

|

|

Workpiece kicks | 1. | Not enough pressure from the | 1. | Raise the Pressure Plate. |

out of sander. |

| pressure plate (84). |

|

|

SKU 98198 | For technical questions, please call | Page 21 |