2.Before operating, make sure the Air Compressor is set up in a well ventilated area, on a flat, level, solid surface well away from any flammable objects.

To Start The Compressor:

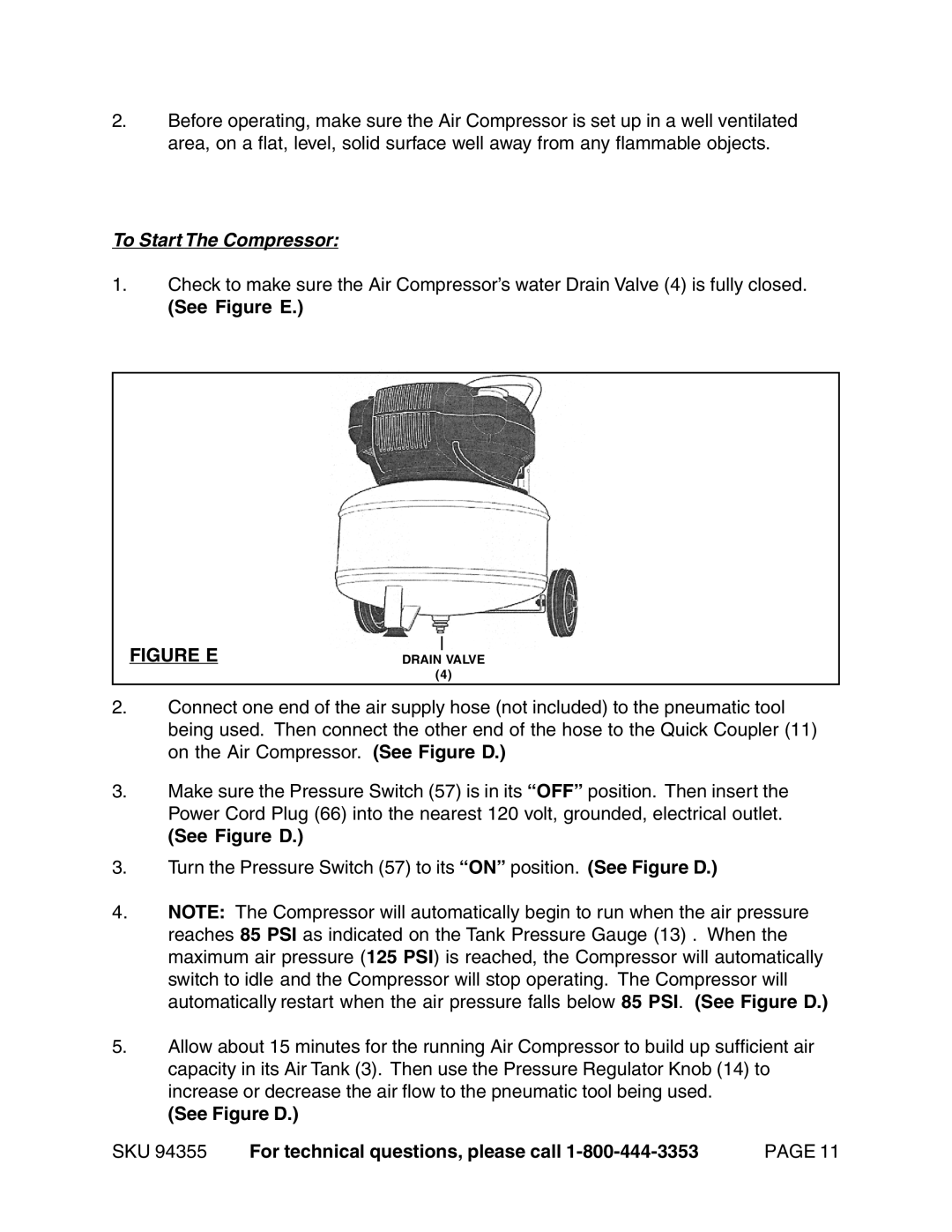

1.Check to make sure the Air Compressor’s water Drain Valve (4) is fully closed.

(See Figure E.)

FIGURE E

DRAIN VALVE

(4)

2.Connect one end of the air supply hose (not included) to the pneumatic tool being used. Then connect the other end of the hose to the Quick Coupler (11) on the Air Compressor. (See Figure D.)

3.Make sure the Pressure Switch (57) is in its “OFF” position. Then insert the Power Cord Plug (66) into the nearest 120 volt, grounded, electrical outlet.

(See Figure D.)

3.Turn the Pressure Switch (57) to its “ON” position. (See Figure D.)

4.NOTE: The Compressor will automatically begin to run when the air pressure reaches 85 PSI as indicated on the Tank Pressure Gauge (13) . When the maximum air pressure (125 PSI) is reached, the Compressor will automatically switch to idle and the Compressor will stop operating. The Compressor will automatically restart when the air pressure falls below 85 PSI. (See Figure D.)

5.Allow about 15 minutes for the running Air Compressor to build up sufficient air capacity in its Air Tank (3). Then use the Pressure Regulator Knob (14) to increase or decrease the air flow to the pneumatic tool being used.

(See Figure D.)

SKU 94355 | For technical questions, please call | PAGE 11 |