HEAD PRESSURE CONTROL

Refrigeration condensing units must efficiently perform at varying ambient conditions. A properly sized unit will adequately perform at even the highest summer ambient temperatures. However, in situations where the system must operate the majority of the time at less than design temperature, a means of providing adequate head pressure for refrigerant flow is desirable. The CDV & CDD units have an adjustable method of head pressure

control.

This system provides year round control of refrigerant head pressure without the use of special refrigerant expansion valves. As the ambient temperature falls, the reciever pressure is allowed to fall to a minimum of 75°F saturated condensing pressure. The reduced discharge pressure at the compressor increases the compressor capacity and lowers the input watts from the compressor motor. The system also uses the reduced ambient temperature to subcool the liquid refrigerant in the condenser. This subcooled liquid also increases system capacity. As a general rule, every one degree of subcooling results in 0.50% increase in system capacity. Together these result in greater efficiency, greater capacity, and reduced run time.

Benefits:

•Automatic

•Energy savings in mild ambient conditions due to reduced compressor discharge pressure and refrigerant subcooling

•Provides easy restart during low ambient conditions.

Operation

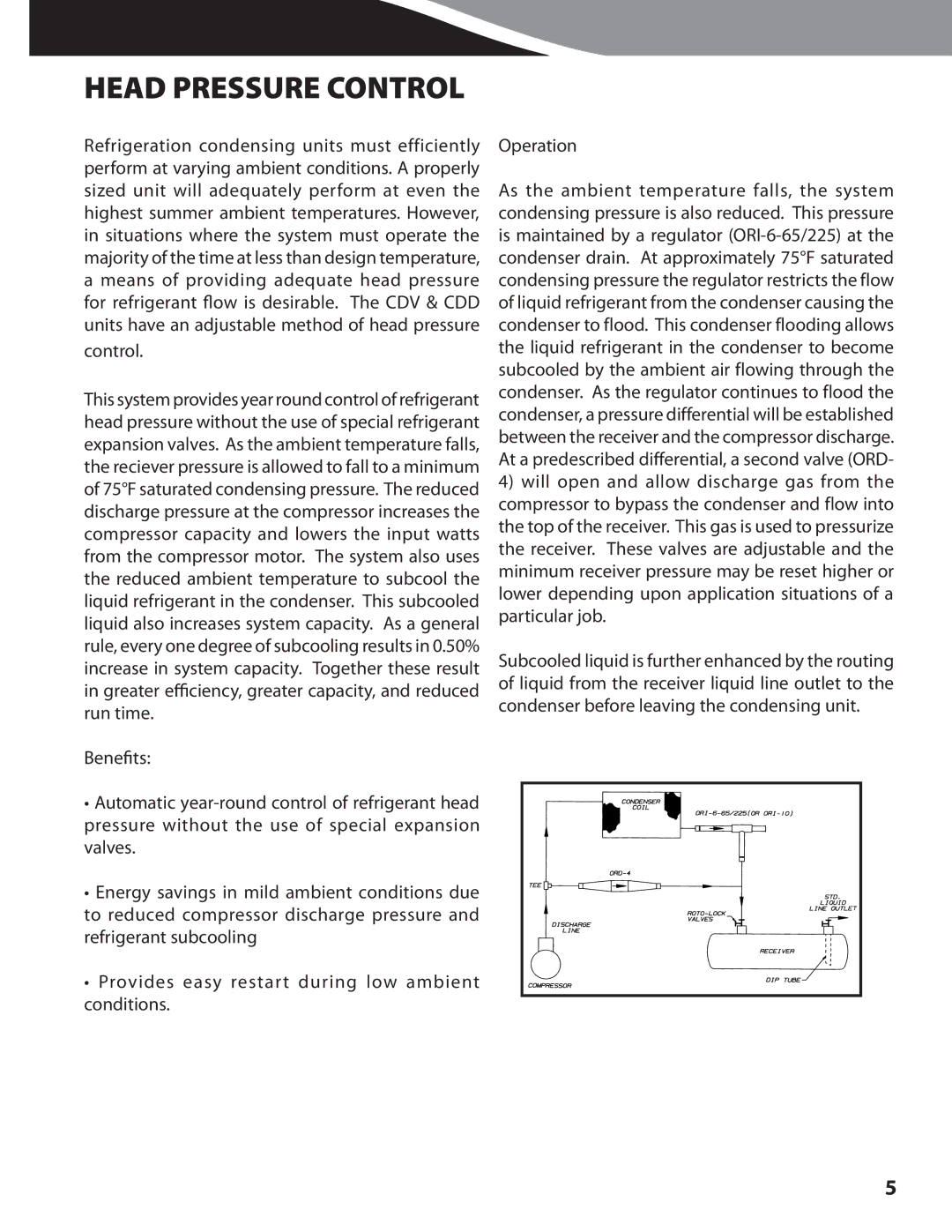

As the ambient temperature falls, the system condensing pressure is also reduced. This pressure is maintained by a regulator

4)will open and allow discharge gas from the compressor to bypass the condenser and flow into the top of the receiver. This gas is used to pressurize the receiver. These valves are adjustable and the minimum receiver pressure may be reset higher or lower depending upon application situations of a particular job.

Subcooled liquid is further enhanced by the routing of liquid from the receiver liquid line outlet to the condenser before leaving the condensing unit.

5