Pressure Control

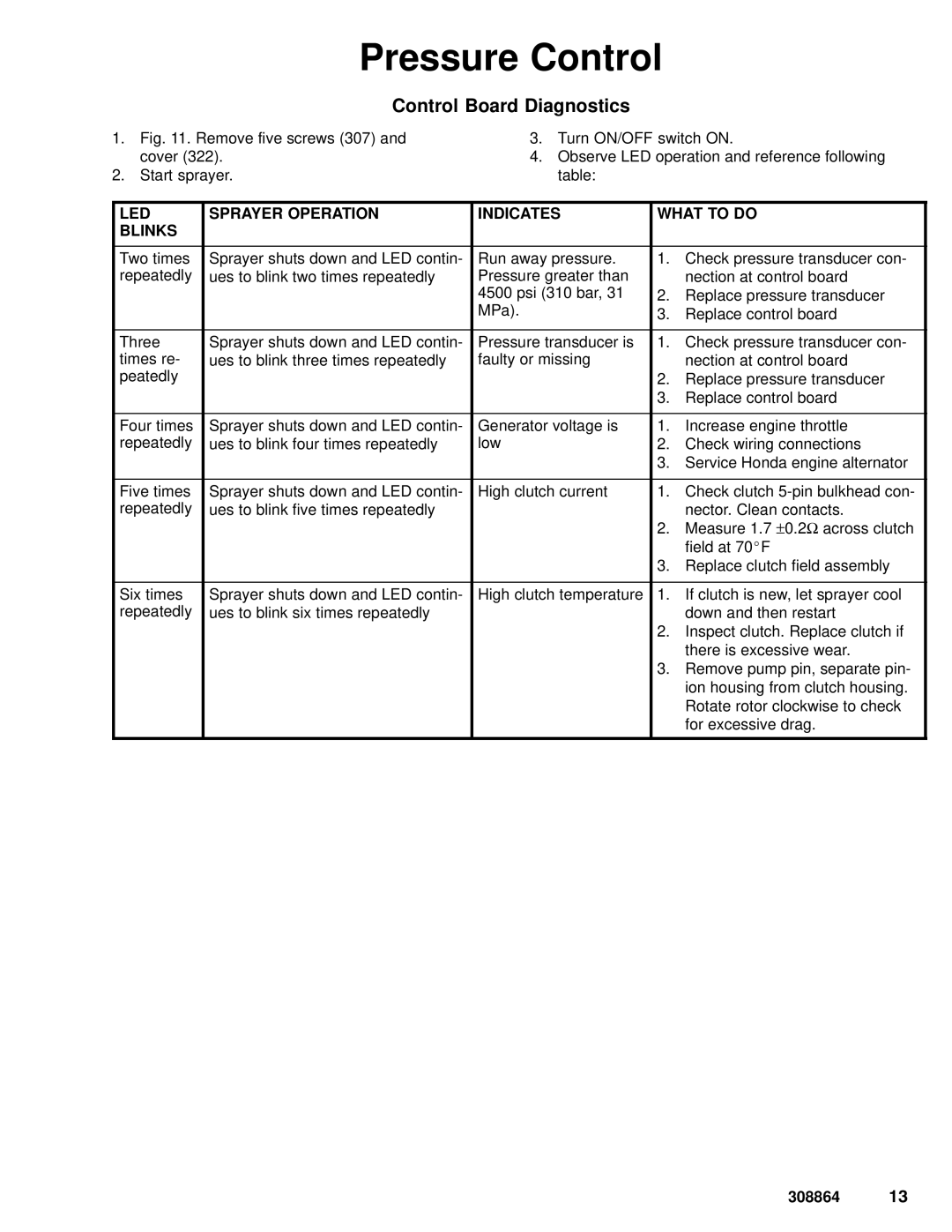

Control Board Diagnostics

1.Fig. 11. Remove five screws (307) and cover (322).

2.Start sprayer.

3.Turn ON/OFF switch ON.

4.Observe LED operation and reference following table:

LED | SPRAYER OPERATION | INDICATES | WHAT TO DO | |

BLINKS |

|

|

|

|

|

|

|

|

|

Two times | Sprayer shuts down and LED contin- | Run away pressure. | 1. | Check pressure transducer con- |

repeatedly | ues to blink two times repeatedly | Pressure greater than |

| nection at control board |

|

| 4500 psi (310 bar, 31 | 2. | Replace pressure transducer |

|

| MPa). | 3. | Replace control board |

|

|

|

|

|

Three | Sprayer shuts down and LED contin- | Pressure transducer is | 1. | Check pressure transducer con- |

times re- | ues to blink three times repeatedly | faulty or missing |

| nection at control board |

peatedly |

|

| 2. | Replace pressure transducer |

|

|

| 3. | Replace control board |

|

|

|

|

|

Four times | Sprayer shuts down and LED contin- | Generator voltage is | 1. | Increase engine throttle |

repeatedly | ues to blink four times repeatedly | low | 2. | Check wiring connections |

|

|

| 3. | Service Honda engine alternator |

|

|

|

|

|

Five times | Sprayer shuts down and LED contin- | High clutch current | 1. | Check clutch |

repeatedly | ues to blink five times repeatedly |

|

| nector. Clean contacts. |

|

|

| 2. | Measure 1.7 ±0.2Ω across clutch |

|

|

|

| field at 70_F |

|

|

| 3. | Replace clutch field assembly |

|

|

|

|

|

Six times | Sprayer shuts down and LED contin- | High clutch temperature | 1. | If clutch is new, let sprayer cool |

repeatedly | ues to blink six times repeatedly |

|

| down and then restart |

|

|

| 2. | Inspect clutch. Replace clutch if |

|

|

|

| there is excessive wear. |

|

|

| 3. | Remove pump pin, separate pin- |

|

|

|

| ion housing from clutch housing. |

|

|

|

| Rotate rotor clockwise to check |

|

|

|

| for excessive drag. |

|

|

|

|

|