English

SPINDLE / QUILL (Fig. N)

Rotate the feed handles counterclockwise to lower spindle to its lowest position. Hand support the spindle securely and move it back and forth around the axis. If there is play, do the following:

1.Loosen the lock nut (1).

2.Turn the screw (2) clockwise to eliminate the play, but without obstructing the upward movement of the spindle.

3.Tighten the lock nut (1).

Fig. N

1

2

![]() WARNING

WARNING

To prevent personal injury, always disconnect the plug from the power source when making any adjustment.

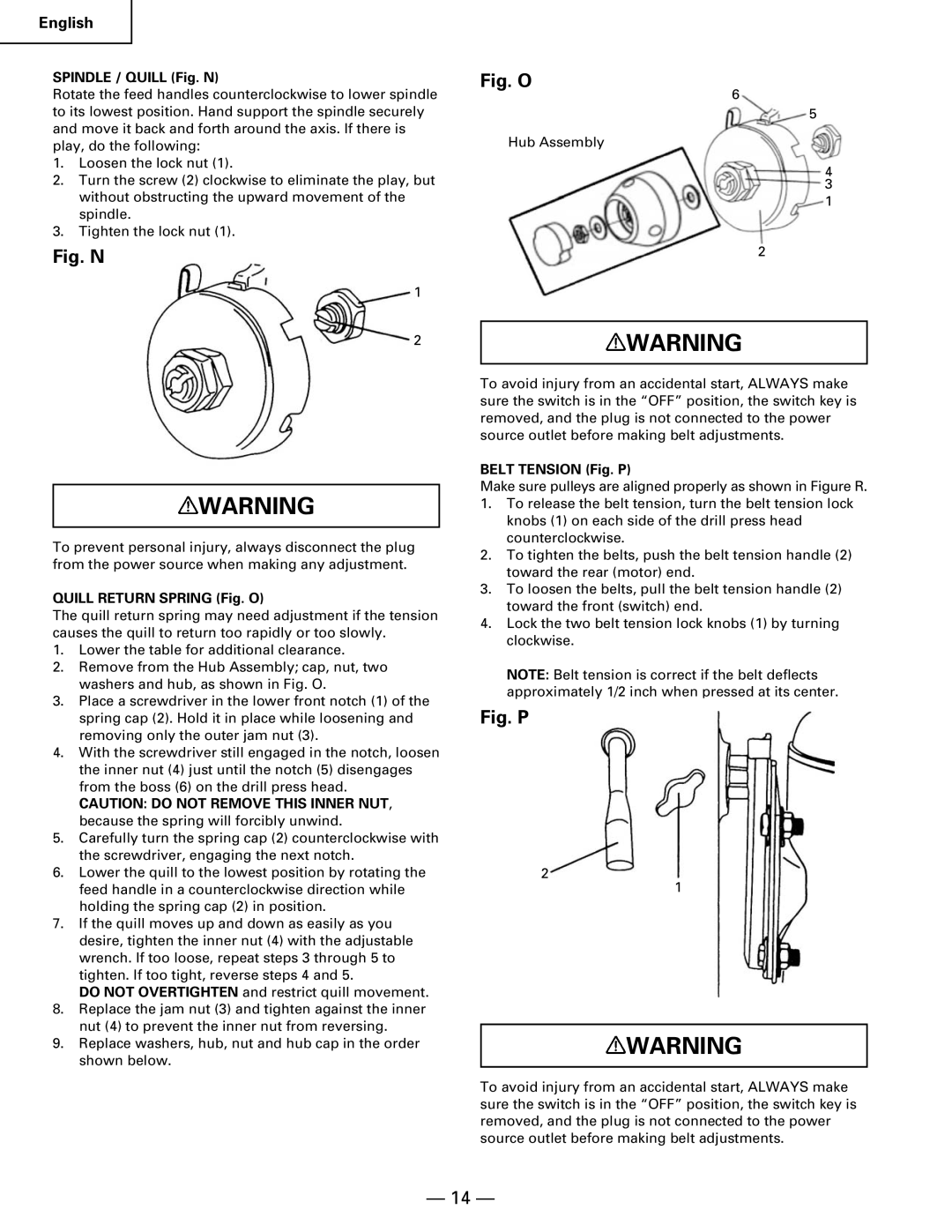

QUILL RETURN SPRING (Fig. O)

The quill return spring may need adjustment if the tension causes the quill to return too rapidly or too slowly.

1.Lower the table for additional clearance.

2.Remove from the Hub Assembly; cap, nut, two washers and hub, as shown in Fig. O.

3.Place a screwdriver in the lower front notch (1) of the spring cap (2). Hold it in place while loosening and removing only the outer jam nut (3).

4.With the screwdriver still engaged in the notch, loosen the inner nut (4) just until the notch (5) disengages from the boss (6) on the drill press head.

CAUTION: DO NOT REMOVE THIS INNER NUT, because the spring will forcibly unwind.

5.Carefully turn the spring cap (2) counterclockwise with the screwdriver, engaging the next notch.

6.Lower the quill to the lowest position by rotating the feed handle in a counterclockwise direction while holding the spring cap (2) in position.

7.If the quill moves up and down as easily as you desire, tighten the inner nut (4) with the adjustable wrench. If too loose, repeat steps 3 through 5 to tighten. If too tight, reverse steps 4 and 5.

DO NOT OVERTIGHTEN and restrict quill movement.

8.Replace the jam nut (3) and tighten against the inner nut (4) to prevent the inner nut from reversing.

9.Replace washers, hub, nut and hub cap in the order shown below.

Fig. O

6

5

Hub Assembly

4

3

1

2

![]() WARNING

WARNING

To avoid injury from an accidental start, ALWAYS make sure the switch is in the “OFF” position, the switch key is removed, and the plug is not connected to the power source outlet before making belt adjustments.

BELT TENSION (Fig. P)

Make sure pulleys are aligned properly as shown in Figure R.

1.To release the belt tension, turn the belt tension lock knobs (1) on each side of the drill press head counterclockwise.

2.To tighten the belts, push the belt tension handle (2) toward the rear (motor) end.

3.To loosen the belts, pull the belt tension handle (2) toward the front (switch) end.

4.Lock the two belt tension lock knobs (1) by turning clockwise.

NOTE: Belt tension is correct if the belt deflects approximately 1/2 inch when pressed at its center.

Fig. P

2

1

![]() WARNING

WARNING

To avoid injury from an accidental start, ALWAYS make sure the switch is in the “OFF” position, the switch key is removed, and the plug is not connected to the power source outlet before making belt adjustments.

— 14 —