English

TROUBLESHOOTING

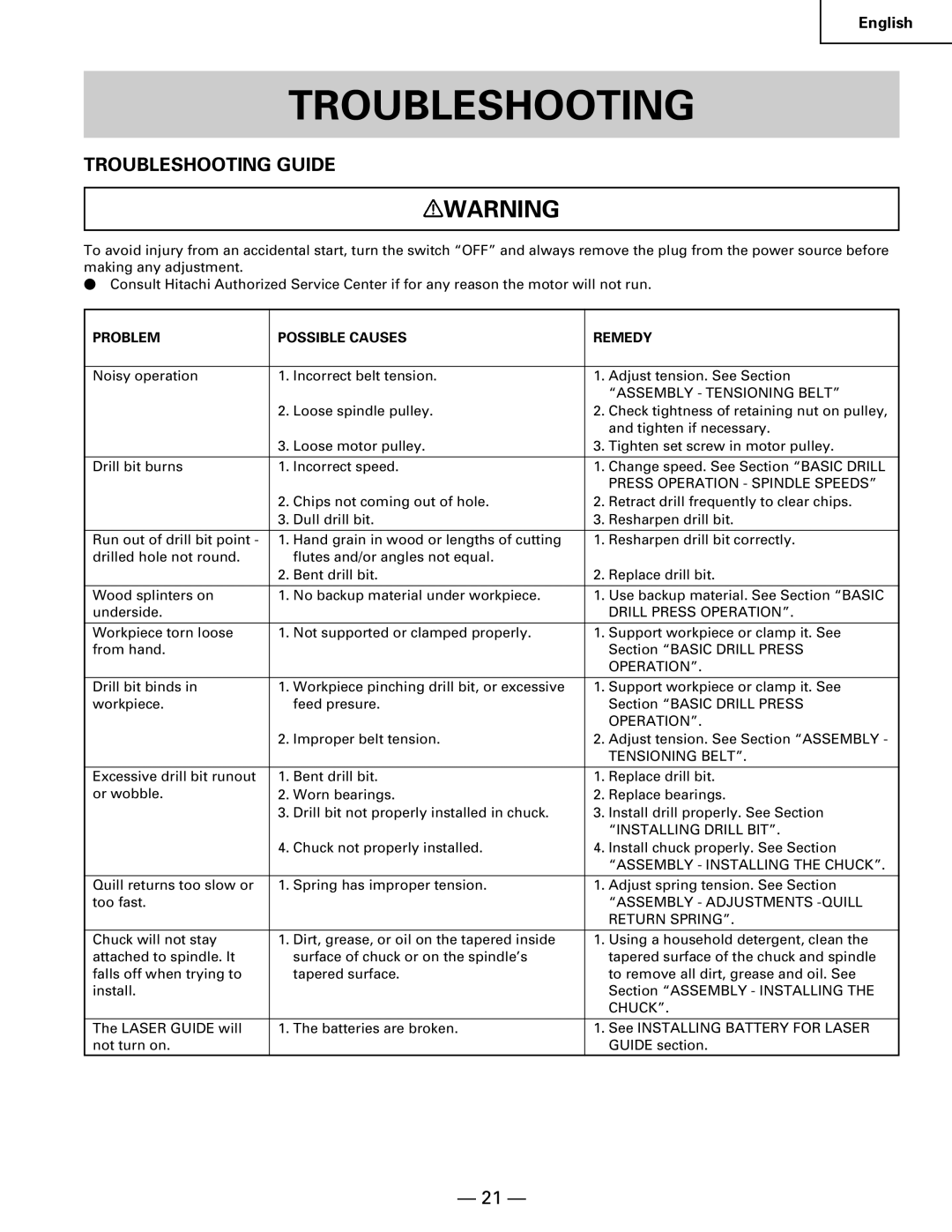

TROUBLESHOOTING GUIDE

![]() WARNING

WARNING

To avoid injury from an accidental start, turn the switch “OFF” and always remove the plug from the power source before making any adjustment.

⬤Consult Hitachi Authorized Service Center if for any reason the motor will not run.

PROBLEM | POSSIBLE CAUSES | REMEDY | ||

|

|

|

|

|

Noisy operation | 1. | Incorrect belt tension. | 1. | Adjust tension. See Section |

|

|

|

| “ASSEMBLY - TENSIONING BELT” |

| 2. | Loose spindle pulley. | 2. | Check tightness of retaining nut on pulley, |

|

|

|

| and tighten if necessary. |

| 3. | Loose motor pulley. | 3. | Tighten set screw in motor pulley. |

|

|

|

|

|

Drill bit burns | 1. | Incorrect speed. | 1. | Change speed. See Section “BASIC DRILL |

|

|

|

| PRESS OPERATION - SPINDLE SPEEDS” |

| 2. | Chips not coming out of hole. | 2. | Retract drill frequently to clear chips. |

| 3. | Dull drill bit. | 3. | Resharpen drill bit. |

|

|

|

|

|

Run out of drill bit point - | 1. | Hand grain in wood or lengths of cutting | 1. | Resharpen drill bit correctly. |

drilled hole not round. |

| flutes and/or angles not equal. |

|

|

| 2. | Bent drill bit. | 2. | Replace drill bit. |

|

|

|

|

|

Wood splinters on | 1. | No backup material under workpiece. | 1. | Use backup material. See Section “BASIC |

underside. |

|

|

| DRILL PRESS OPERATION”. |

|

|

|

|

|

Workpiece torn loose | 1. | Not supported or clamped properly. | 1. | Support workpiece or clamp it. See |

from hand. |

|

|

| Section “BASIC DRILL PRESS |

|

|

|

| OPERATION”. |

|

|

|

|

|

Drill bit binds in | 1. | Workpiece pinching drill bit, or excessive | 1. | Support workpiece or clamp it. See |

workpiece. |

| feed presure. |

| Section “BASIC DRILL PRESS |

|

|

|

| OPERATION”. |

| 2. | Improper belt tension. | 2. | Adjust tension. See Section “ASSEMBLY - |

|

|

|

| TENSIONING BELT”. |

|

|

|

|

|

Excessive drill bit runout | 1. | Bent drill bit. | 1. | Replace drill bit. |

or wobble. | 2. | Worn bearings. | 2. | Replace bearings. |

| 3. | Drill bit not properly installed in chuck. | 3. | Install drill properly. See Section |

|

|

|

| “INSTALLING DRILL BIT”. |

| 4. | Chuck not properly installed. | 4. | Install chuck properly. See Section |

|

|

|

| “ASSEMBLY - INSTALLING THE CHUCK”. |

|

|

|

|

|

Quill returns too slow or | 1. | Spring has improper tension. | 1. | Adjust spring tension. See Section |

too fast. |

|

|

| “ASSEMBLY - ADJUSTMENTS |

|

|

|

| RETURN SPRING”. |

|

|

|

|

|

Chuck will not stay | 1. | Dirt, grease, or oil on the tapered inside | 1. | Using a household detergent, clean the |

attached to spindle. It |

| surface of chuck or on the spindle’s |

| tapered surface of the chuck and spindle |

falls off when trying to |

| tapered surface. |

| to remove all dirt, grease and oil. See |

install. |

|

|

| Section “ASSEMBLY - INSTALLING THE |

|

|

|

| CHUCK”. |

|

|

| ||

The LASER GUIDE will | 1. The batteries are broken. | 1. See INSTALLING BATTERY FOR LASER | ||

not turn on. |

|

|

| GUIDE section. |

— 21 —