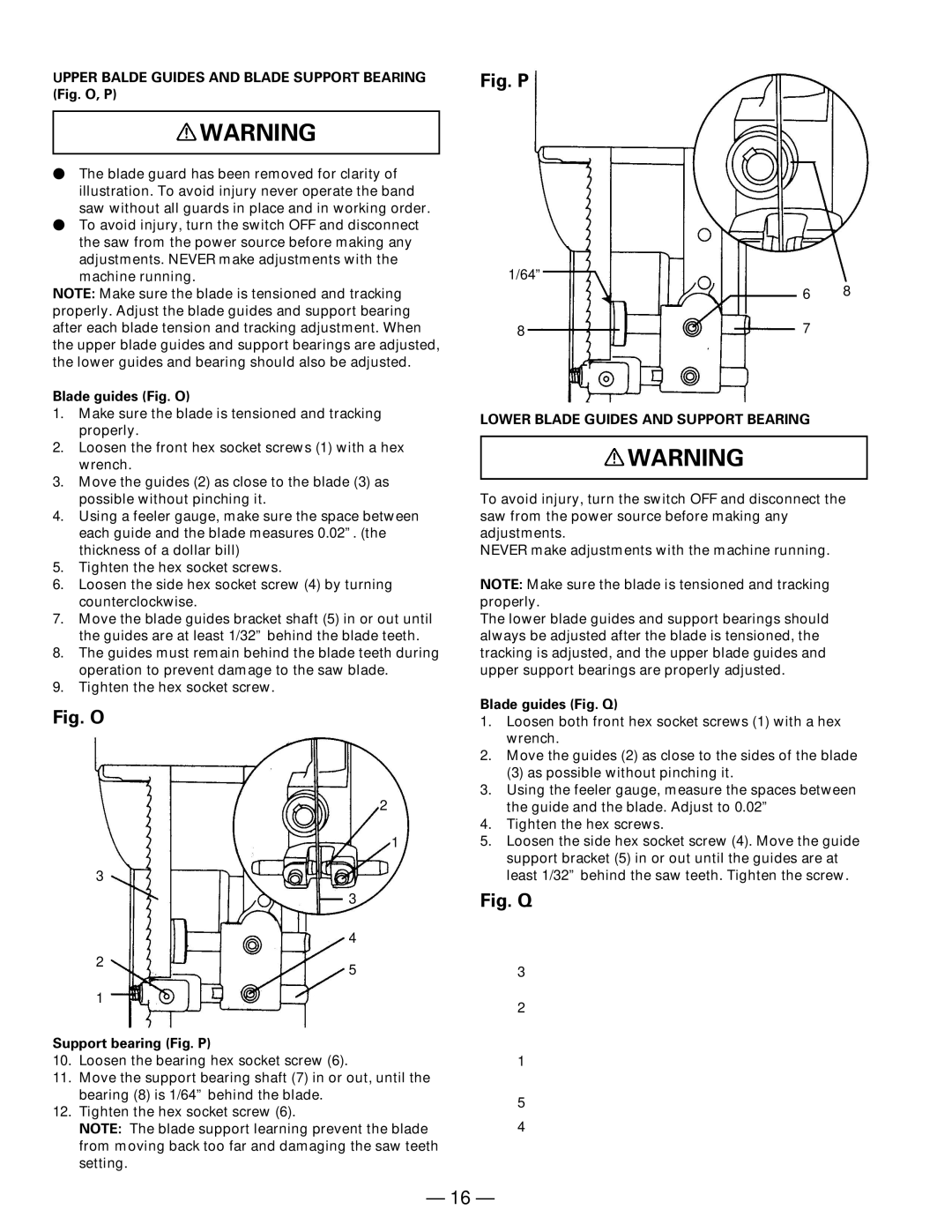

UPPER BALDE GUIDES AND BLADE SUPPORT BEARING (Fig. O, P)

![]() WARNING

WARNING

⬤The blade guard has been removed for clarity of illustration. To avoid injury never operate the band saw without all guards in place and in working order.

⬤To avoid injury, turn the switch OFF and disconnect the saw from the power source before making any

adjustments. NEVER make adjustments with the machine running.

NOTE: Make sure the blade is tensioned and tracking properly. Adjust the blade guides and support bearing after each blade tension and tracking adjustment. When the upper blade guides and support bearings are adjusted, the lower guides and bearing should also be adjusted.

Blade guides (Fig. O)

1.Make sure the blade is tensioned and tracking properly.

2.Loosen the front hex socket screws (1) with a hex wrench.

3.Move the guides (2) as close to the blade (3) as possible without pinching it.

4.Using a feeler gauge, make sure the space between each guide and the blade measures 0.02”. (the thickness of a dollar bill)

5.Tighten the hex socket screws.

6.Loosen the side hex socket screw (4) by turning counterclockwise.

7.Move the blade guides bracket shaft (5) in or out until the guides are at least 1/32” behind the blade teeth.

8.The guides must remain behind the blade teeth during operation to prevent damage to the saw blade.

9.Tighten the hex socket screw.

Fig. O

Fig. P

1/64”

6 8

8 | 7 |

LOWER BLADE GUIDES AND SUPPORT BEARING

![]() WARNING

WARNING

To avoid injury, turn the switch OFF and disconnect the saw from the power source before making any adjustments.

NEVER make adjustments with the machine running.

NOTE: Make sure the blade is tensioned and tracking properly.

The lower blade guides and support bearings should always be adjusted after the blade is tensioned, the tracking is adjusted, and the upper blade guides and upper support bearings are properly adjusted.

Blade guides (Fig. Q)

1. | Loosen both front hex socket screws (1) with a hex |

| wrench. |

2. | Move the guides (2) as close to the sides of the blade |

| (3) as possible without pinching it. |

3. | Using the feeler gauge, measure the spaces between |

3

2

1

2

1

3

4

5

| the guide and the blade. Adjust to 0.02” |

4. | Tighten the hex screws. |

5. | Loosen the side hex socket screw (4). Move the guide |

| support bracket (5) in or out until the guides are at |

| least 1/32” behind the saw teeth. Tighten the screw. |

Fig. Q

3

2

Support bearing (Fig. P)

10.Loosen the bearing hex socket screw (6).

11.Move the support bearing shaft (7) in or out, until the bearing (8) is 1/64” behind the blade.

12.Tighten the hex socket screw (6).

NOTE: The blade support learning prevent the blade from moving back too far and damaging the saw teeth setting.

1

5

4

— 16 —