English

6. Using a Metallic Block (Fig. 11).

Dimension of workpiece being cut

| Vise (B) | |

| Metallic block | |

Vise (A) | Dimension of | |

metallic block | ||

|

(Should be slightly smaller than the workpiece being cut)

Fig. 11

When the

CUT-OFF WHEEL DISMOUNTING AND MOUNTING

![]() WARNING: Always turn off the trigger switch and disconnect the power plug from the receptacle before dismounting or mounting a wheel, to prevent accidental injury.

WARNING: Always turn off the trigger switch and disconnect the power plug from the receptacle before dismounting or mounting a wheel, to prevent accidental injury.

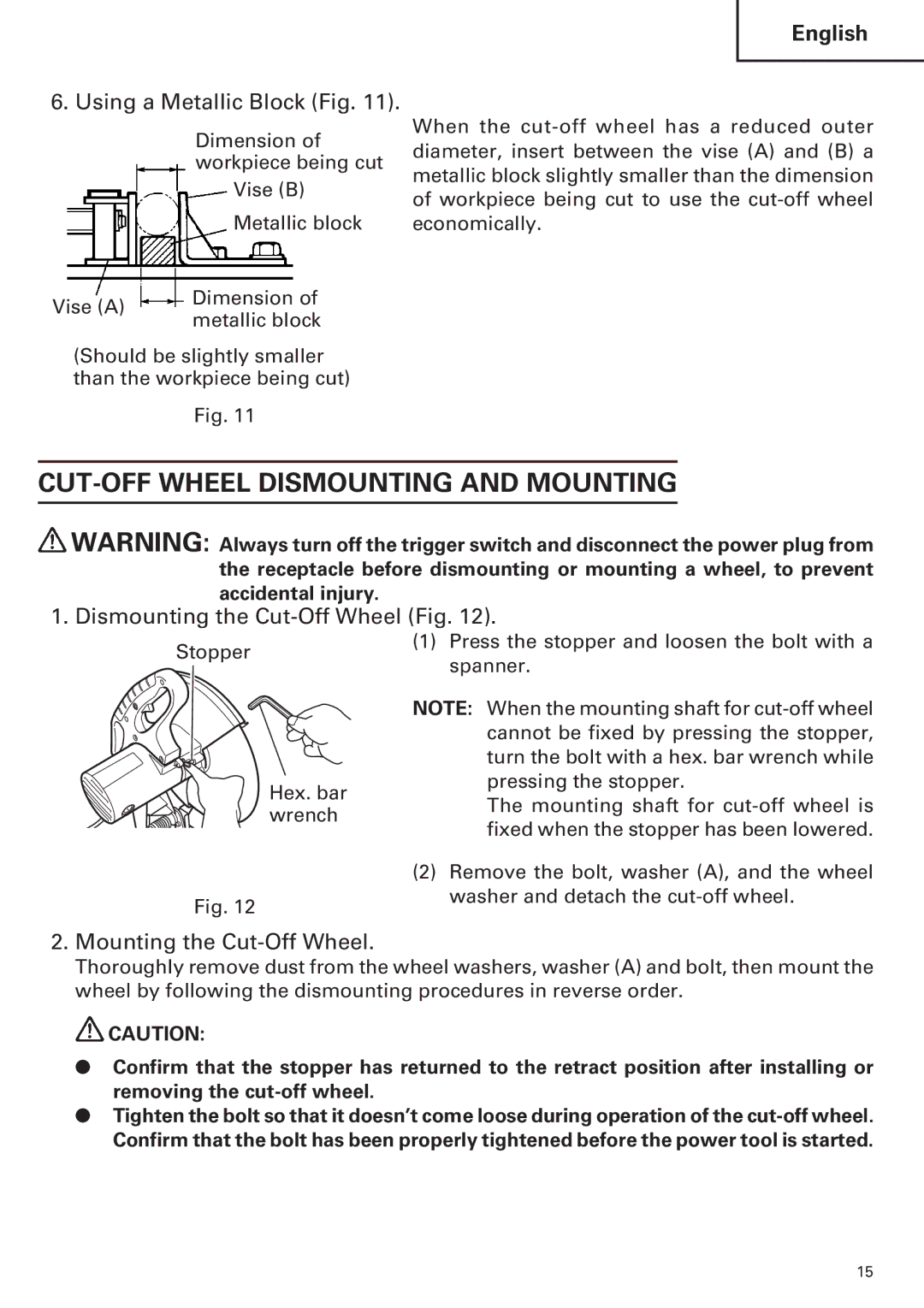

1. Dismounting the Cut-Off Wheel (Fig. 12).

Stopper

Hex. bar wrench

Fig. 12

(1)Press the stopper and loosen the bolt with a spanner.

NOTE: When the mounting shaft for

The mounting shaft for

(2)Remove the bolt, washer (A), and the wheel washer and detach the

2.Mounting the Cut-Off Wheel.

Thoroughly remove dust from the wheel washers, washer (A) and bolt, then mount the wheel by following the dismounting procedures in reverse order.

![]() CAUTION:

CAUTION:

●Confirm that the stopper has returned to the retract position after installing or removing the

●Tighten the bolt so that it doesn’t come loose during operation of the

15