English

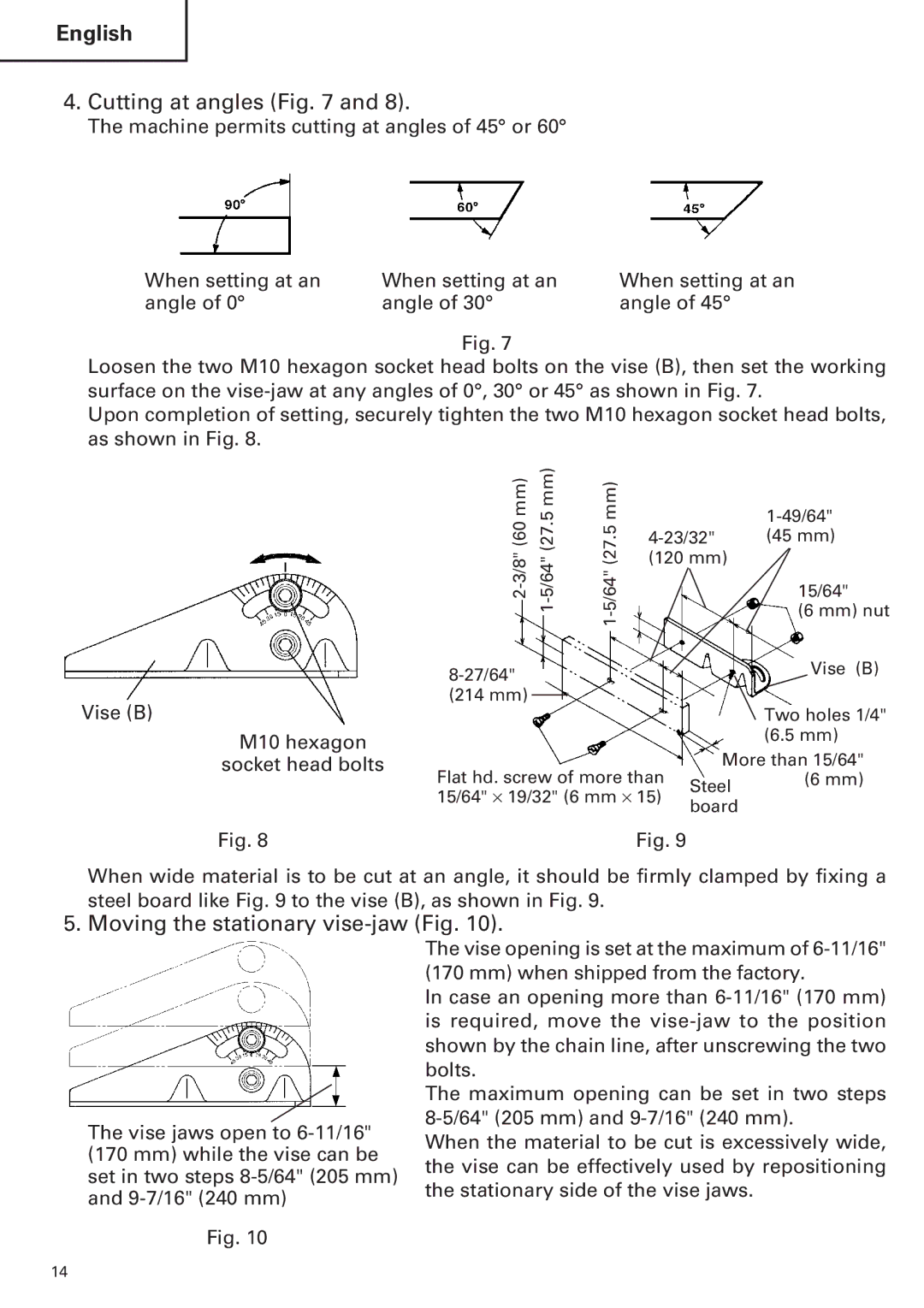

4.Cutting at angles (Fig. 7 and 8).

The machine permits cutting at angles of 45° or 60°

When setting at an | When setting at an | When setting at an |

angle of 0° | angle of 30° | angle of 45° |

Fig. 7

Loosen the two M10 hexagon socket head bolts on the vise (B), then set the working surface on the

Upon completion of setting, securely tighten the two M10 hexagon socket head bolts, as shown in Fig. 8.

|

| ||||

|

| (6 mm) nut | |||

|

|

| (45 mm) | ||

|

| (120 mm) |

| ||

|

|

|

|

| 15/64" |

|

| 1 |

|

|

|

|

|

|

| Vise (B) | |

|

|

|

|

| |

(214 mm) |

|

|

|

|

|

Vise (B) |

|

|

|

| Two holes 1/4" |

M10 hexagon |

|

|

|

| (6.5 mm) |

|

|

| More than 15/64" | ||

socket head bolts |

|

|

| ||

Flat hd. screw of more than | Steel | (6 mm) | |||

15/64" ⋅ 19/32" (6 mm ⋅ 15) |

| ||||

board |

| ||||

|

|

|

| ||

Fig. 8 |

| Fig. 9 |

|

|

|

When wide material is to be cut at an angle, it should be firmly clamped by fixing a steel board like Fig. 9 to the vise (B), as shown in Fig. 9.

5. Moving the stationary vise-jaw (Fig. 10).

The vise jaws open to

The vise opening is set at the maximum of

In case an opening more than

The maximum opening can be set in two steps

When the material to be cut is excessively wide, the vise can be effectively used by repositioning the stationary side of the vise jaws.

Fig. 10

14