English

4. Cutting metallic materials

(1) Adjust the speed Dial between scales “3” and “4”.

(2) Set the orbital position to “0” or “I”.

(3)Always use an appropriate cutting fluid (spindle oil, soapy water, etc.). When a liquid cutting fluid is not avaiable, apply grease to the back surface of the material to be cut.

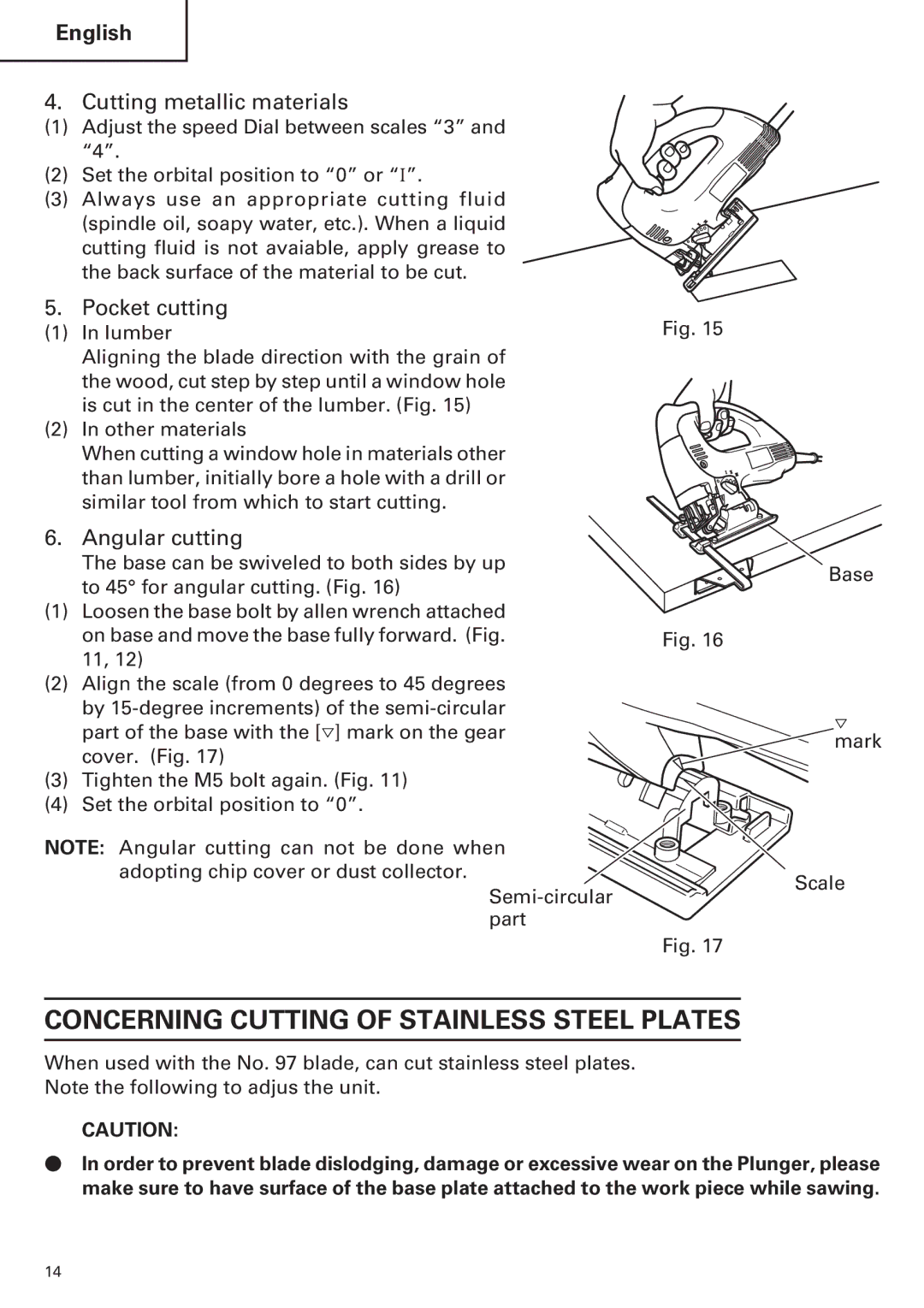

5.Pocket cutting

(1) In lumber

Aligning the blade direction with the grain of the wood, cut step by step until a window hole is cut in the center of the lumber. (Fig. 15)

(2) In other materials

When cutting a window hole in materials other than lumber, initially bore a hole with a drill or similar tool from which to start cutting.

6.Angular cutting

The base can be swiveled to both sides by up

to 45° for angular cutting. (Fig. 16)

(1)Loosen the base bolt by allen wrench attached on base and move the base fully forward. (Fig. 11, 12)

(2)Align the scale (from 0 degrees to 45 degrees by ![]() ] mark on the gear cover. (Fig. 17)

] mark on the gear cover. (Fig. 17)

(3)Tighten the M5 bolt again. (Fig. 11)

(4)Set the orbital position to “0”.

NOTE: Angular cutting can not be done when adopting chip cover or dust collector.

Fig. 15

Base

Fig. 16

mark

Scale

Fig. 17

CONCERNING CUTTING OF STAINLESS STEEL PLATES

When used with the No. 97 blade, can cut stainless steel plates.

Note the following to adjus the unit.

![]() CAUTION:

CAUTION:

⬤In order to prevent blade dislodging, damage or excessive wear on the Plunger, please make sure to have surface of the base plate attached to the work piece while sawing.

14