English

MAINTENANCE AND INSPECTION

![]() WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

1.Inspecting the drill bits

Since use of a dull tool will cause motor malfunctioning and degraded efficiency, replace the drill bit with a new one or resharpening without delay when abrasion is noted.

2.Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be loosened, retighten them immediately.

![]() WARNING: Using this rotary hammer with loosened screws is extremely dangerous.

WARNING: Using this rotary hammer with loosened screws is extremely dangerous.

3.Maintenance of the motor

The motor unit winding is the very “heart” of the power tool. Exercise due care to ensure the winding does not become damaged and/or wet with oil or water.

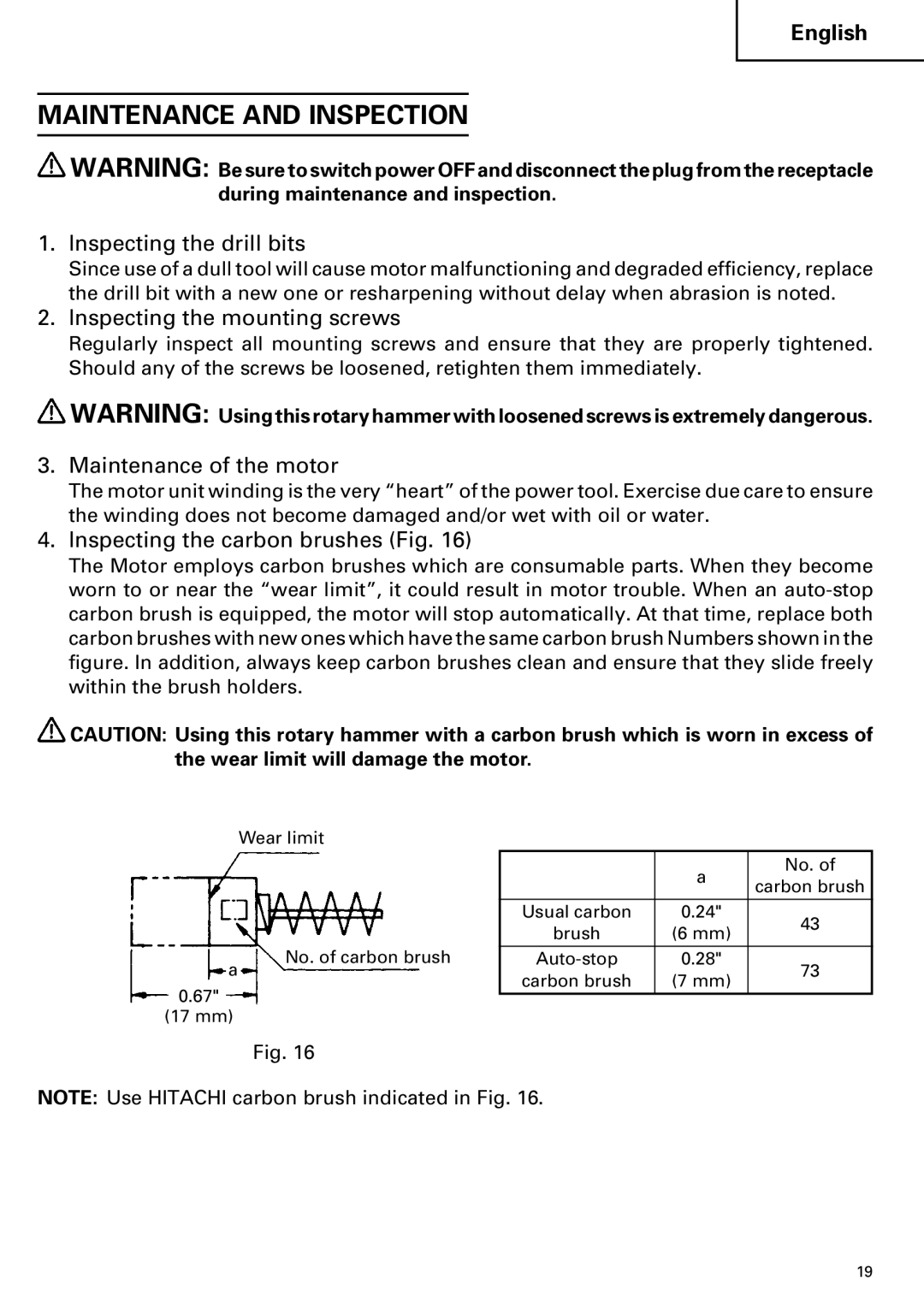

4.Inspecting the carbon brushes (Fig. 16)

The Motor employs carbon brushes which are consumable parts. When they become worn to or near the “wear limit”, it could result in motor trouble. When an

![]() CAUTION: Using this rotary hammer with a carbon brush which is worn in excess of the wear limit will damage the motor.

CAUTION: Using this rotary hammer with a carbon brush which is worn in excess of the wear limit will damage the motor.

Wear limit |

|

|

|

|

| a | No. of |

|

| carbon brush | |

|

|

| |

| Usual carbon | 0.24" | 43 |

| brush | (6 mm) | |

|

| ||

No. of carbon brush | 0.28" | 73 | |

a | carbon brush | (7 mm) | |

0.67" |

| ||

|

|

| |

(17 mm) |

|

|

|

Fig. 16

NOTE: Use HITACHI carbon brush indicated in Fig. 16.

19