English

MAINTENANCE AND INSPECTION

![]() WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

1.Inspecting the tool

Since use of a dull tool will degrade efficiency and cause possible motor malfunction, sharpen or replace the tool as soon as abrasion is noted.

2.Inspecting the screws

Regularly inspect all screws and ensure that they are properly tightened. Should any of the screws be loosened, retighten them immediately.

![]() WARNING: Using this demolition hammer with loosened screws is extremely dangerous.

WARNING: Using this demolition hammer with loosened screws is extremely dangerous.

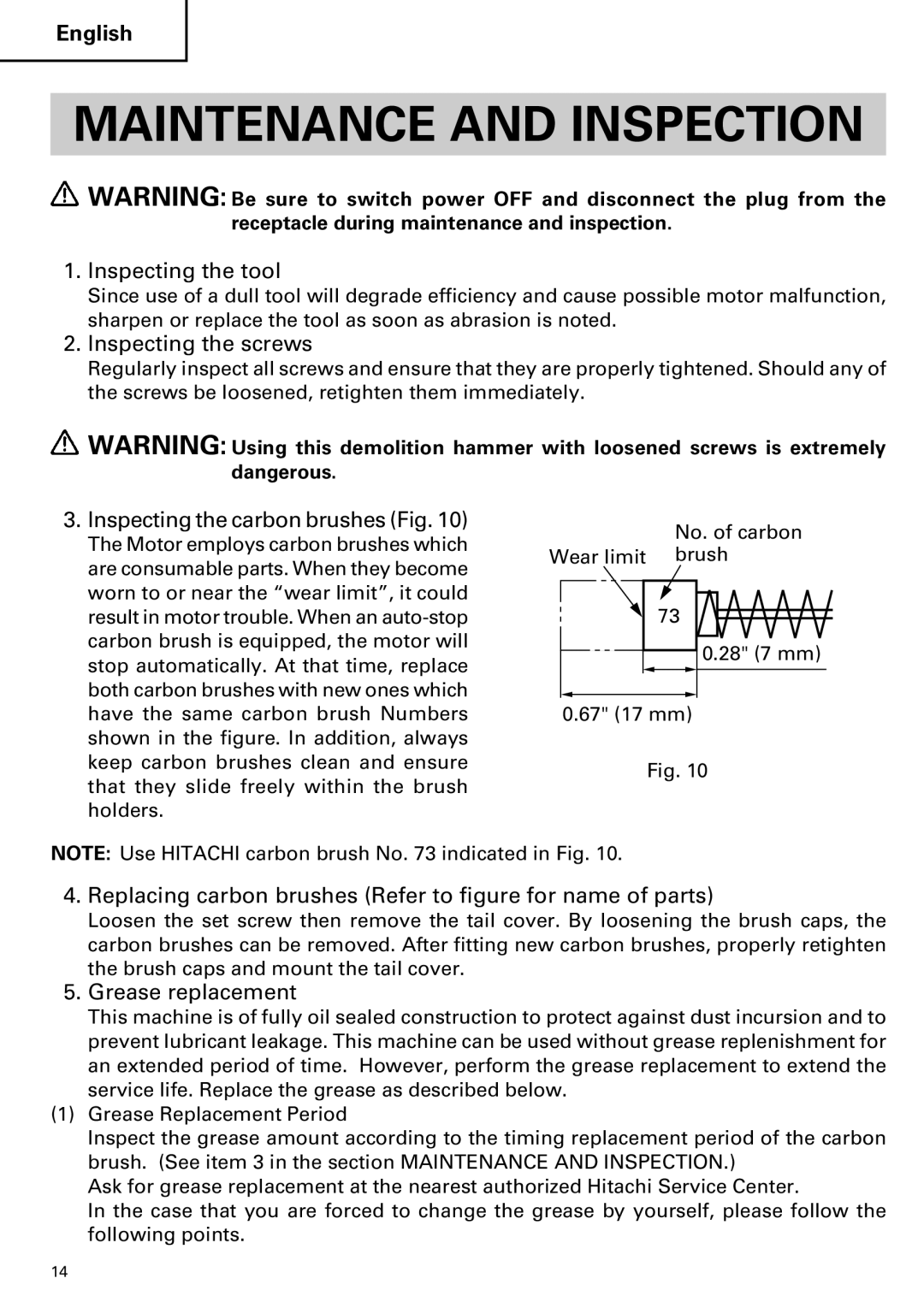

3.Inspecting the carbon brushes (Fig. 10)

The Motor employs carbon brushes which are consumable parts. When they become worn to or near the “wear limit”, it could result in motor trouble. When an

No. of carbon

Wear limit brush

73

![]()

![]()

![]()

![]() 0.28" (7 mm)

0.28" (7 mm)

0.67" (17 mm)

Fig. 10

NOTE: Use HITACHI carbon brush No. 73 indicated in Fig. 10.

4.Replacing carbon brushes (Refer to figure for name of parts)

Loosen the set screw then remove the tail cover. By loosening the brush caps, the carbon brushes can be removed. After fitting new carbon brushes, properly retighten the brush caps and mount the tail cover.

5.Grease replacement

This machine is of fully oil sealed construction to protect against dust incursion and to prevent lubricant leakage. This machine can be used without grease replenishment for an extended period of time. However, perform the grease replacement to extend the service life. Replace the grease as described below.

(1)Grease Replacement Period

Inspect the grease amount according to the timing replacement period of the carbon brush. (See item 3 in the section MAINTENANCE AND INSPECTION.)

Ask for grease replacement at the nearest authorized Hitachi Service Center.

In the case that you are forced to change the grease by yourself, please follow the following points.

14