Advertencia

Avertissement

Contents

Meanings of Signal Words

Important Safety Information

General Safety Rules for ALL Battery Operated Tools

Safety

English

Never operate without all guards in place

Specific Safety Rules

English

Important Safety Instructions for Battery Charger

Make Them Available to Other Users Owners of this Tool

Cordless Impact Driver/Wrench

Functional Description

Model

Name of Parts

Specifications

Battery Charger

Cordless Impact Driver

WR9DM2 WR12DM2

Cordless Impact Wrench

Applications

Assembly and Operation

Removal and Installation Method of Battery

Handle Latch Recharge Insert Able Battery Pull out

English

RED

Using the light equipped hook

Before USE

Operation

English

Batteries Rance Hook cover Indentation

Selecting the socket matched to the bolt WR12DM2, WR9DM2

Installing the bit WH12DM2, WH9DM2

Installing a socket , 15-1 WR12DM2

Removing the bit WH12DM2, WH9DM2

Switch operation

Tightening and loosening screws

Number of screw tightenings possible WH12DM, WH9DM

Resting the unit after continuous work

Operational Cautions

Tightening and loosening bolts

Number of bolt tightened possible WR12DM2, WR9DM2

Confirm the tightening torque

Tightening torque

Use a tightening time suitable for the screw

Holding the tool

Kgf·cm In-lbs 100 1000

For WR12DM2

For WH9DM2

Bolt Steel plate Thickness t Nut

For WR9DM2

⋅ 2-5/32 M16 ⋅ 55 F10T bolt

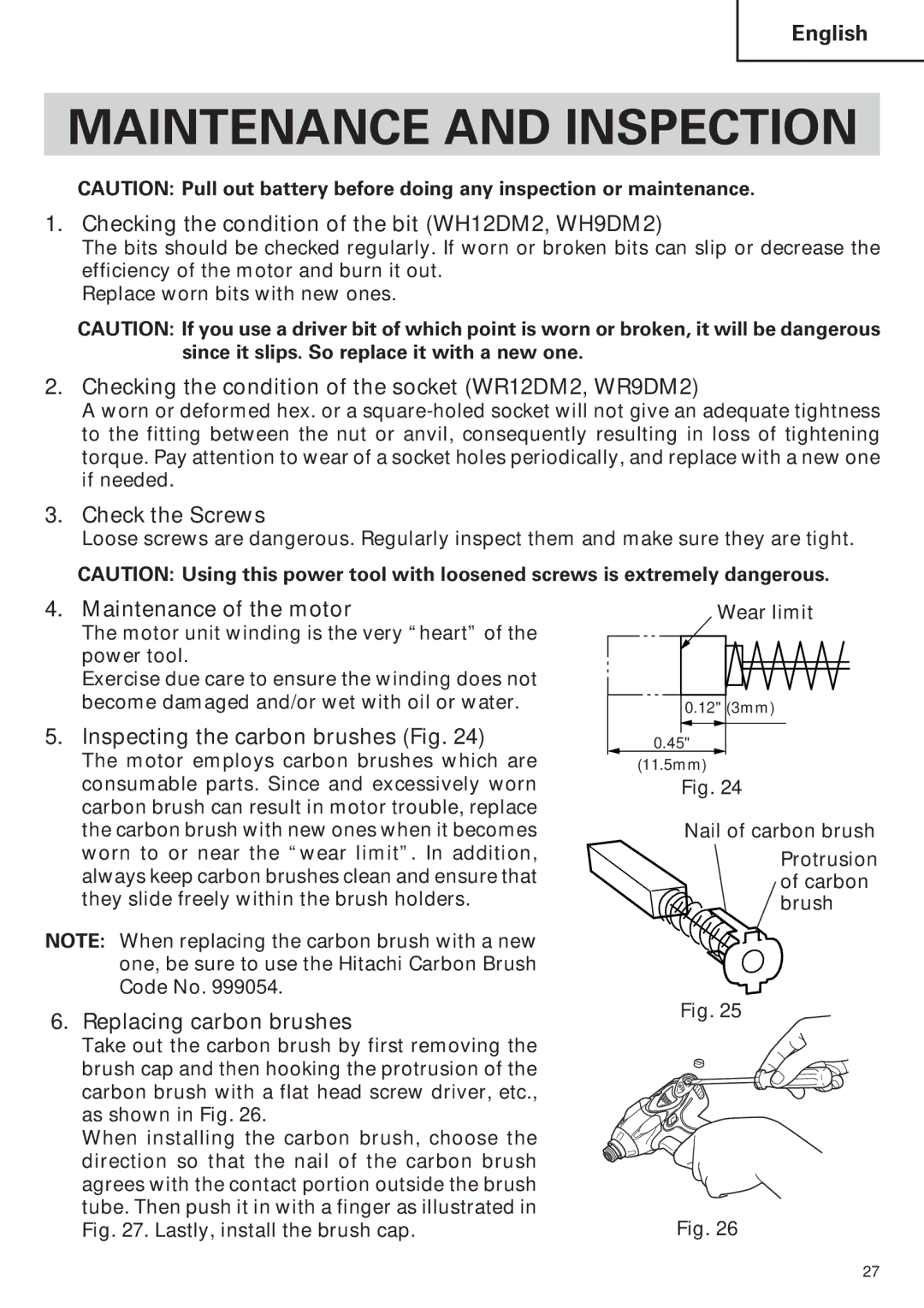

Maintenance and Inspection

Check for Dust

Disposal of the exhausted battery Storage

Service and repairs

Service parts list

Accessories

Standard Accessories

Battery

Drill chuck adapter set Code No

Phillips bit

Hexagonal socket

Wood working drill bit Code No

WR12DM2, WR9DM2

Sockets

Long Socket

9.5 mm

Extension bar WR12DM2, WR9DM2

Universal joint WR12DM2, WR9DM2

12.7 mm

Duct socket WR12DM2

Corner attachment Model EW-14R WR12DM2

Mm adapter WR12DM2

Bit adaptor WR12DM2

2 12.7 mm Square adaptor WR9DM2

Signification DES Mots D’AVERTISSEMENT

Informations Importantes DE Sécurité

Conserver CES Instructions

Securite

Avertissement

Min Rotations ou mouvements de va-et-vient par minute

Regles DE Securite Specifiques

Courant continu

Vitesse à vide

Français

Intensité nominale d’entrée CA ampères

Français

Français

Visseuse à percussion à batterie/Clé à choc à batterie

Description Fonctionnelle

Modele

NOM DES Parties

Modèle

Chargeur de batterie

Visseuse à percussion à batterie

Orifice

Clé à choc à batterie

Méthode DE Recharge

Méthode DE Retrait ET D’INSTALLATION DE LA Batterie

Assemblage ET Fonctionnement

Utilisations

Français

Verte

Avant L’UTILISATION

Utilisation

Utilisation du crochet avec lampe

Français

Ne pas trop serrer la vis. Cela pourrait abîmer le filetage

Mise en place de la mèche WH12DM2

Retrait de la mèche WH12DM2, WH9DM2

Mise in place d’une douille , 15-1 WR12DM2

En appuyant sur le côté L du bouton-poussoir

Type de bague de retenue , 15-2 WR9DM2

Fonctionnement de l’interrupteur

Serrage et desserrage des vis

Serrage et desserrage des boulon

Utiliser le couple de serrage adapté à chaque type de vis

Precautions Dutilisation

Repos de l’appareil après un travail continu

Couple de serrage

Vérifier le couple de serrage

Pour WH9DM2

Pour WH12DM2

Pour WR12DM2

Pour WR9DM2

Boulon Epaisseur de la Plaque d’acier t Ecrou

Français

Entretien ET Inspection

Rangement

Remplacement d’un balai en carbone

Vérifier s’il y a de la poussière

Mise au rebut d’une batterie usée

Liste des pièces de rechange

EB1220BL N de code

Accessoires

Accessoires Standard

Batterie

Mèche Phillips

Douille hexagonale

Foret pour le forage du bois N de Code

Jeu d’adaptateur de mandrin de foreuse N de Code

Douilles

Utiliser la foreuse en vente WR12DM2, WR9DM2

Pour WR9DM2 Tableau

Douille longue

9,5 mm

Barre de rallonge WR12DM2, WR9DM2

Joint universel WR12DM2, WR9DM2

12,7 mm

Adaptateur 9,5 mm WR12DM2

Dimension S

Douille à tubulure WR12DM2

Fixation en coin Modèle EW-14R WR12DM2

Adaptateur carré de 1/2 12,7 mm WR9DM2

Adaptateur de mèche WR12DM2

Cet adaptateur est utilisé pour serrer des petites vis M6

Significado DE LAS Palabras DE Señalización

Información Importante Sobre Seguridad

Guarde Estas Instrucciones

Seguridad

Advertencia

Utilice la herramienta correcta

Normas Específicos DE Seguridad

Español

25 7,5 100 150

Español

Español

Atornillador/Llave de impacto a batería

Descripción Funcional

Modelo

Nomenclatura

La torsión es de pernos 9/16

Modelo

Velocidad sin carga 2800/min

Capacidad

Tiempo de carga Aprox min Cargador Tensión de carga

Llave de impacto a batería

Cargador de baterías

Monofàsica 120 V CA, 60 Hz

Método DE Carga

Montaje Y Operación

Aplicaciones

Método DE Extracción E Instalación DE LA Batería

Lámpara piloto Orificio de instalación de la batería

Precaución

Roja

Tabla

Antes DE LA Utilización

Operación

Empleo del gancho equipado con luz

El diámetro más grande queda en dirección opuesta

Negativo -. Fig

Interruptor

De la flecha. Fig

Alineélas con las indicaciones del gancho y

Tipo anillo de retención , 15-2 WR9DM2

Instalación de la punta del atornillador WH12DM2, WH9DM2

Extracción de la broca WH12DM2, WH9DM2

Instalacón de un receptáculo , 15-1 WR12DM2

Operación de conmutación

Apretado y aflojado de pernos

RPulsador L PresionarPresionar

13. Número posible de aprietes WR12DM2, WR9DM2

11. Número posible de aprietes WH12DM2, WH9DM2

Precauciones Operacionales

Español

Para WH9DM2

Para WH12DM2

Para WR12DM2

Para WR9DM2

Perno Tuerca Grosor de la plancha de acero t

Completamente descargado

Mantenimiento de motor

Mantenimiento E Inspección

Comprobación de las condiciones de la broca WH12DM2, WH9DM2

Comprobación de los tornillos

Almacenamiento

Reemplazar el carbón de contacto

Comprobación del polvo

Eliminación de las baterías agotadas

Modificaciones

Lista de repuestos

UC14YF21

Accesorios

Accesorios Estándar

WH12DM2, WH9DM2 1. Batería

Broca Phillips

Receptáculo hexagonal para tuercas y pernos

Broca para taladrar madera Nº de código

Juego adaptador de portabrocas Nº de código

WR12DM2, WR9DM2 1. Battería

Cubos

Para WR9DM2 Tabla

Cubo largo

Barra de extensión WR12DM2, WR9DM2

Junta cardánica WR12DM2, WR9DM2

Nº de código Dimensión B, S Modelo

Cubo para conductos WR12DM2

Accesorio para esquinas Modelo EW-14R WR12DM2

Adaptador de 9,5 mm WR12DM2

Adaptador de brocas WR12DM2

Adaptador rectangular de 1/2 12,7 mm WR9DM2

1R D2 2M

107

Kestrel Road Mississauga on L5T 1Z5

![]() CAUTION: Pull out battery before doing any inspection or maintenance.

CAUTION: Pull out battery before doing any inspection or maintenance.![]() CAUTION: If you use a driver bit of which point is worn or broken, it will be dangerous since it slips. So replace it with a new one.

CAUTION: If you use a driver bit of which point is worn or broken, it will be dangerous since it slips. So replace it with a new one.![]() CAUTION: Using this power tool with loosened screws is extremely dangerous.

CAUTION: Using this power tool with loosened screws is extremely dangerous.