X200 specifications

The Hitachi X200 series is a line of cutting-edge industrial drives designed to enhance operational efficiency and performance across various applications. Developed with advanced technologies, the X200 drives are geared toward providing seamless integration, superior control, and robust reliability in manufacturing environments.One of the standout features of the Hitachi X200 is its exceptional control capabilities. The drive employs vector control technology, enabling precise and efficient motor control across a range of speeds. This allows users to achieve optimal performance in applications that require a high level of accuracy and responsiveness. The built-in auto-tuning function simplifies the setup process, adjusting parameters automatically to ensure that the drive operates at its best.

Another key characteristic of the X200 series is its energy efficiency. The drives are designed to minimize energy consumption while maximizing output. With features like energy-saving mode and advanced power management, operators can significantly reduce operational costs. This focus on sustainability is becoming increasingly important as industries strive to meet environmental regulations and improve their carbon footprint.

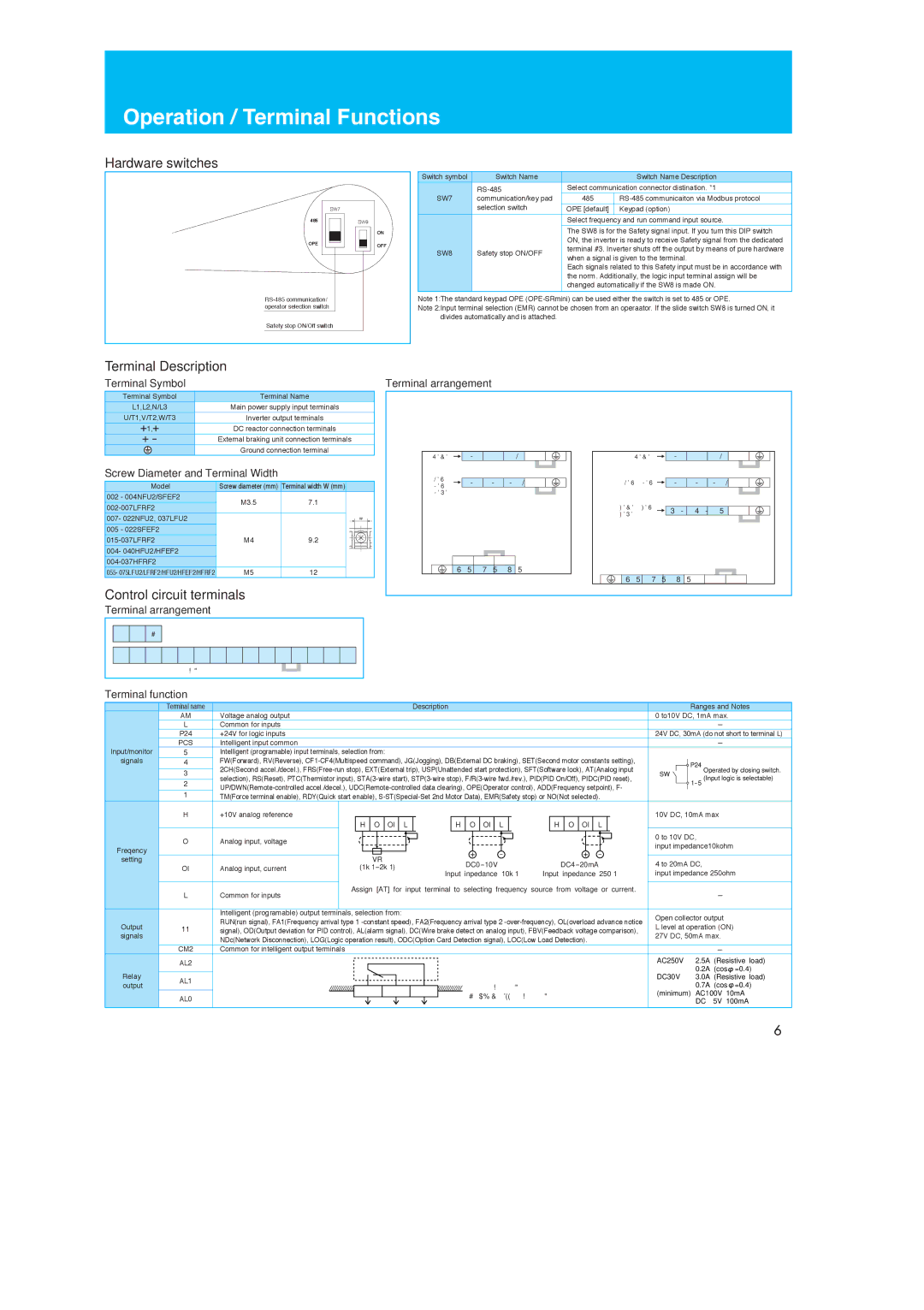

The X200 series also showcases robust communication capabilities. It supports multiple communication protocols, including Modbus, Profibus, and Ethernet/IP. This flexibility ensures that users can easily integrate the drives into existing automation systems and communicate seamlessly with other devices. Additionally, the drive supports remote monitoring and control, allowing for real-time performance tracking and adjustments from anywhere.

Reliability is paramount in industrial settings, and the Hitachi X200 does not disappoint. It is built with high-quality components that ensure durability and longevity even in harsh operating conditions. The drives have a wide operational temperature range and are designed to withstand vibrations, making them suitable for challenging environments.

Furthermore, the X200 series comes equipped with advanced safety features, including built-in motor overload protection and fault diagnosis capabilities. This ensures that any potential issues are identified promptly, minimizing downtime and improving overall reliability.

In conclusion, the Hitachi X200 series offers a comprehensive solution for industries looking to enhance their motor control and automation capabilities. With its advanced control technologies, energy efficiency, robust communication options, and high reliability, the X200 drives stand out as a top choice for modern industrial applications. These features combine to deliver not just performance but also a pathway toward greater operational efficiency and sustainability.