SECTION 4 − OPERATION

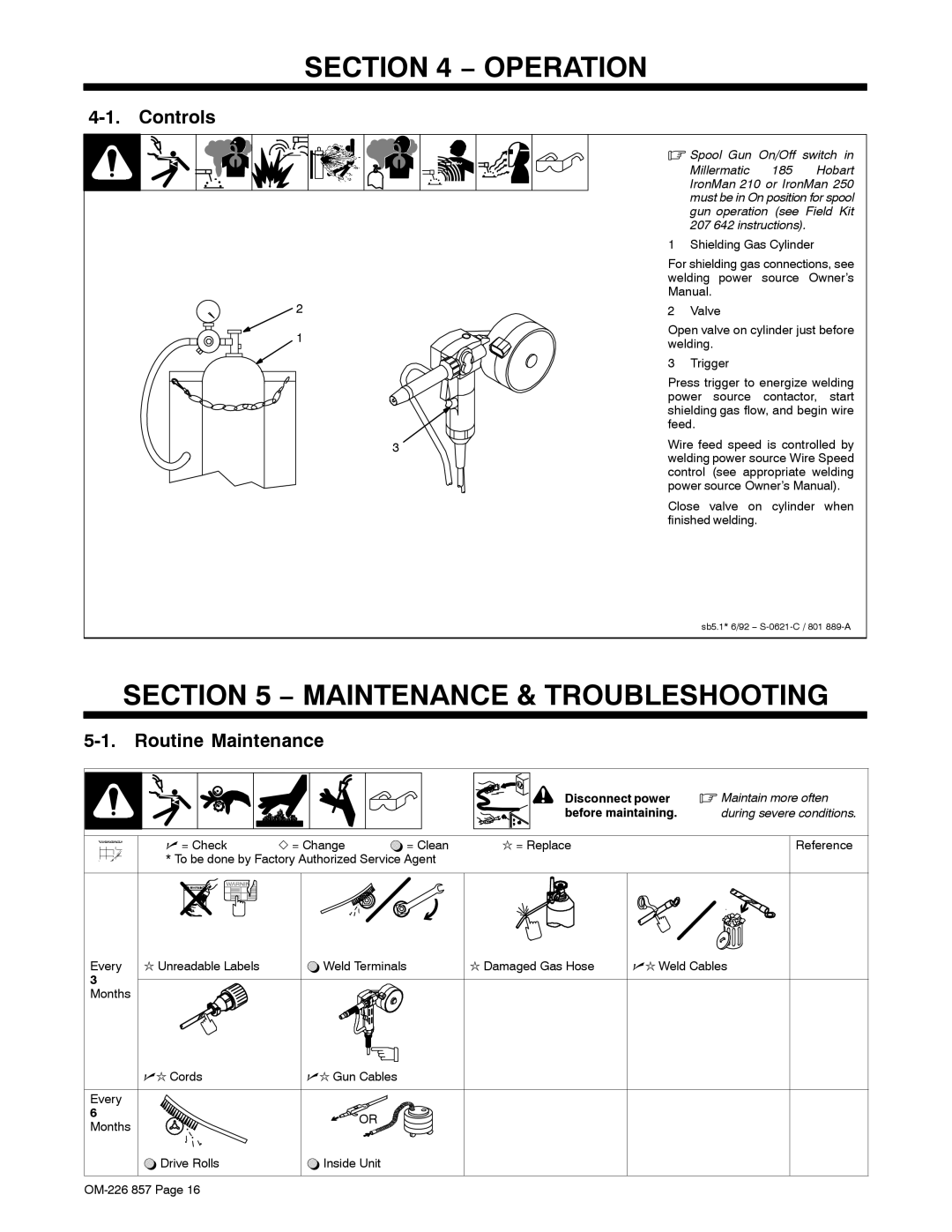

4-1. Controls

2

1

| . Spool Gun | On/Off | switch in | ||

|

| Millermatic | 185 | Hobart | |

|

| IronMan 210 or IronMan 250 | |||

|

| must be in On position for spool | |||

|

| gun operation (see Field Kit | |||

|

| 207 642 instructions). | |||

| 1 | Shielding Gas Cylinder | |||

| For shielding gas connections, see | ||||

| welding | power | source | Owner’s | |

| Manual. |

|

|

| |

| 2 | Valve |

|

| |

| Open valve on cylinder just before | ||||

| welding. |

|

| ||

| 3 | Trigger |

|

| |

| Press trigger to energize welding | ||||

| power | source | contactor, start | ||

| shielding gas flow, and begin wire | ||||

| feed. |

|

|

| |

3 | Wire feed speed is controlled by | ||||

| welding power source Wire Speed | ||||

| control | (see appropriate welding | |||

| power source Owner’s Manual). | ||||

Close valve on cylinder when finished welding.

sb5.1* 6/92 −

SECTION 5 − MAINTENANCE & TROUBLESHOOTING

5-1. Routine Maintenance

|

|

| ! Disconnect power | . Maintain more often |

|

|

| before maintaining. | during severe conditions. |

n = Check | Z = Change | ~ = Clean | l = Replace | Reference |

* To be done by Factory Authorized Service Agent |

|

| ||

Every l Unreadable Labels | ~ Weld Terminals | l Damaged Gas Hose | nl Weld Cables |

3 |

|

|

|

Months |

|

|

|

nl Cords | nl Gun Cables | |

Every |

| |

6 | OR | |

Months | ||

|

~Drive Rolls

~Inside Unit